What is Global Automobile Solid Stabilizer Bar Market?

The Global Automobile Solid Stabilizer Bar Market refers to the industry focused on the production and distribution of solid stabilizer bars used in vehicles worldwide. These bars are crucial components in a vehicle's suspension system, designed to reduce body roll during cornering and improve overall stability. By connecting opposite wheels through short lever arms linked by a torsion spring, stabilizer bars help maintain a vehicle's balance, especially during sharp turns or uneven road conditions. The market encompasses various types of stabilizer bars, including those made from different materials like cast iron, steel, and alloys, each offering unique benefits in terms of strength, weight, and cost. The demand for these bars is driven by the need for enhanced vehicle safety and performance, as well as the growing automotive industry globally. As vehicles become more advanced and consumer expectations for safety and handling increase, the importance of high-quality stabilizer bars continues to rise. This market is also influenced by technological advancements and innovations aimed at improving the efficiency and effectiveness of stabilizer bars.

Cast iron, Steel, Alloy in the Global Automobile Solid Stabilizer Bar Market:

Cast iron, steel, and alloy materials play significant roles in the Global Automobile Solid Stabilizer Bar Market, each offering distinct advantages and characteristics. Cast iron stabilizer bars are known for their durability and cost-effectiveness. They are typically used in heavy-duty applications where strength and resistance to wear are paramount. Cast iron's high carbon content makes it exceptionally hard and capable of withstanding significant stress, making it a reliable choice for stabilizer bars in commercial vehicles and larger passenger cars. However, cast iron is relatively heavy, which can impact the overall weight of the vehicle and, consequently, its fuel efficiency. Steel stabilizer bars, on the other hand, are widely favored for their balance of strength, flexibility, and weight. Steel is less brittle than cast iron, allowing it to absorb and dissipate energy more effectively during impacts and sharp turns. This flexibility helps in maintaining vehicle stability and improving ride comfort. Additionally, steel stabilizer bars can be manufactured using various processes, such as hot rolling or cold forging, to enhance their mechanical properties. The versatility of steel makes it suitable for a broad range of vehicles, from compact cars to SUVs and light trucks. Moreover, advancements in steel manufacturing, such as the development of high-strength, low-alloy (HSLA) steels, have further improved the performance and weight efficiency of steel stabilizer bars. Alloy stabilizer bars represent the cutting edge of material technology in the automotive industry. These bars are made from a combination of metals, typically including elements like chromium, nickel, and molybdenum, which enhance their mechanical properties. Alloy stabilizer bars are designed to offer superior strength-to-weight ratios, making them ideal for high-performance and luxury vehicles where both performance and efficiency are critical. The use of alloys allows for the creation of stabilizer bars that are not only strong and durable but also lightweight, contributing to better fuel efficiency and handling characteristics. Additionally, alloys can be engineered to provide specific properties, such as increased corrosion resistance, which is particularly beneficial in regions with harsh weather conditions or where road salt is commonly used. In summary, the choice of material for automobile solid stabilizer bars—whether cast iron, steel, or alloy—depends on the specific requirements of the vehicle and the desired balance between cost, performance, and durability. Each material offers unique benefits that cater to different segments of the automotive market, from heavy-duty commercial vehicles to high-performance sports cars. As the automotive industry continues to evolve, the development and application of advanced materials in stabilizer bars will play a crucial role in enhancing vehicle safety, performance, and efficiency.

Passenger Car, Commercial Vehicle in the Global Automobile Solid Stabilizer Bar Market:

The usage of solid stabilizer bars in passenger cars and commercial vehicles highlights their importance in enhancing vehicle stability and safety. In passenger cars, stabilizer bars are essential for providing a smooth and controlled driving experience. These bars help reduce body roll during cornering, ensuring that the vehicle remains stable and predictable even during sharp turns or sudden maneuvers. This not only enhances the comfort of the passengers but also significantly improves safety by reducing the risk of rollover accidents. In modern passenger cars, where the focus is on delivering a balanced combination of performance, comfort, and safety, the role of stabilizer bars is indispensable. They contribute to the overall handling characteristics of the vehicle, making it more responsive and easier to control, which is particularly important in urban driving conditions where quick and precise maneuvers are often required. In commercial vehicles, the role of stabilizer bars is even more critical due to the larger size and higher center of gravity of these vehicles. Commercial vehicles, such as trucks and buses, are more prone to body roll and instability, especially when carrying heavy loads or navigating through uneven terrain. Solid stabilizer bars in these vehicles help maintain stability by distributing the load more evenly across the suspension system and reducing the sway that can occur during turns or sudden changes in direction. This not only enhances the safety of the vehicle but also improves the comfort of the driver and passengers, reducing fatigue and the risk of accidents. In addition, stabilizer bars in commercial vehicles contribute to better tire wear and fuel efficiency by ensuring that the tires maintain optimal contact with the road surface, reducing unnecessary friction and drag. Furthermore, the use of advanced materials and technologies in the manufacturing of stabilizer bars has led to significant improvements in their performance and durability. For instance, the development of high-strength steel and alloy stabilizer bars has enabled manufacturers to produce bars that are both lightweight and exceptionally strong, providing superior stability without adding unnecessary weight to the vehicle. This is particularly beneficial in commercial vehicles, where weight savings can translate into increased payload capacity and better fuel efficiency. Additionally, the integration of electronic stability control systems with stabilizer bars has further enhanced their effectiveness, allowing for real-time adjustments to the suspension system based on driving conditions and vehicle dynamics. In conclusion, the usage of solid stabilizer bars in passenger cars and commercial vehicles is crucial for ensuring vehicle stability, safety, and performance. These components play a vital role in reducing body roll, improving handling, and enhancing overall driving comfort. As the automotive industry continues to advance, the importance of high-quality stabilizer bars will only grow, driven by the increasing demand for safer, more efficient, and more comfortable vehicles. The ongoing development of new materials and technologies will further enhance the capabilities of stabilizer bars, making them an integral part of modern vehicle design and engineering.

Global Automobile Solid Stabilizer Bar Market Outlook:

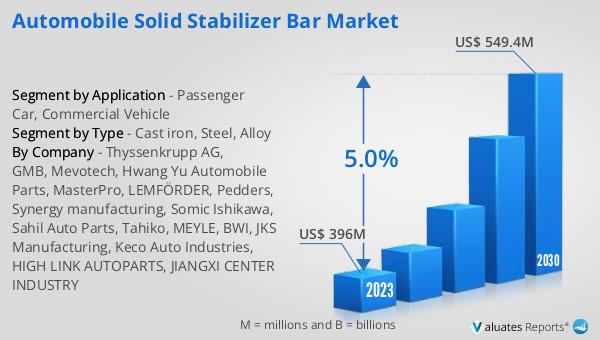

Devices that keep your car stable are essential in the automotive industry, and the global market for Automobile Solid Stabilizer Bars reflects this importance. In 2023, the market was valued at approximately US$ 396 million. Looking ahead, it is projected to grow significantly, reaching an estimated value of US$ 549.4 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. The increasing demand for vehicle safety and performance, coupled with advancements in stabilizer bar technology, are key factors driving this market expansion. As vehicles become more sophisticated and consumer expectations for stability and handling continue to rise, the role of solid stabilizer bars in ensuring a smooth and safe driving experience becomes even more critical. This market outlook underscores the growing recognition of the importance of stabilizer bars in the automotive industry and their contribution to vehicle safety and performance.

| Report Metric | Details |

| Report Name | Automobile Solid Stabilizer Bar Market |

| Accounted market size in 2023 | US$ 396 million |

| Forecasted market size in 2030 | US$ 549.4 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thyssenkrupp AG, GMB, Mevotech, Hwang Yu Automobile Parts, MasterPro, LEMFÖRDER, Pedders, Synergy manufacturing, Somic Ishikawa, Sahil Auto Parts, Tahiko, MEYLE, BWI, JKS Manufacturing, Keco Auto Industries, HIGH LINK AUTOPARTS, JIANGXI CENTER INDUSTRY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |