What is Global Nitrogen Generator Market?

The global nitrogen generator market is a rapidly evolving sector that focuses on the production and distribution of nitrogen gas generators. These generators are essential for various industries that require a consistent and reliable supply of nitrogen gas. Nitrogen generators work by separating nitrogen molecules from the air, providing a cost-effective and efficient solution for industries that need nitrogen for their operations. The market for nitrogen generators is driven by the increasing demand for nitrogen in industries such as food and beverage, chemical and petrochemical, electronics, and general industrial applications. The global nitrogen generator market is characterized by technological advancements, increasing industrialization, and the need for sustainable and efficient gas generation solutions. As industries continue to grow and evolve, the demand for nitrogen generators is expected to rise, making this market a crucial component of the global industrial landscape.

PSA Nitrogen Generator, Membrane Nitrogen Generator in the Global Nitrogen Generator Market:

PSA (Pressure Swing Adsorption) nitrogen generators and membrane nitrogen generators are two primary types of nitrogen generators used in the global nitrogen generator market. PSA nitrogen generators operate by using a process called pressure swing adsorption, where compressed air is passed through a bed of carbon molecular sieve (CMS) material. The CMS material adsorbs oxygen and other gases, allowing nitrogen to pass through as the product gas. This method is highly efficient and can produce high-purity nitrogen gas, making it suitable for applications that require a high level of nitrogen purity. PSA nitrogen generators are widely used in industries such as food and beverage, electronics, and pharmaceuticals due to their reliability and ability to produce nitrogen on-demand. On the other hand, membrane nitrogen generators use a different technology to separate nitrogen from the air. These generators employ semi-permeable membranes that allow nitrogen to pass through while retaining other gases. The compressed air is fed into the membrane module, where the nitrogen molecules permeate through the membrane, resulting in a stream of nitrogen gas. Membrane nitrogen generators are known for their simplicity, low maintenance, and energy efficiency. They are often used in applications where moderate nitrogen purity is sufficient, such as in the chemical and petrochemical industries, fire prevention, and tire inflation. Both PSA and membrane nitrogen generators have their unique advantages and are chosen based on the specific requirements of the application. PSA nitrogen generators are preferred for applications that demand high-purity nitrogen, while membrane nitrogen generators are favored for their energy efficiency and lower operational costs. The choice between the two types of generators depends on factors such as the required nitrogen purity, flow rate, and overall cost considerations. In the global nitrogen generator market, PSA nitrogen generators hold a significant share due to their ability to produce high-purity nitrogen gas. These generators are commonly used in industries where the quality of nitrogen is critical, such as in the food and beverage industry for packaging and preservation, in the electronics industry for manufacturing processes, and in the pharmaceutical industry for maintaining sterile environments. The high demand for pure nitrogen in these sectors drives the adoption of PSA nitrogen generators. Membrane nitrogen generators, while not as widely used as PSA generators, still play a crucial role in the market. Their energy efficiency and low maintenance requirements make them an attractive option for industries that do not require extremely high-purity nitrogen. For example, in the chemical and petrochemical industries, membrane nitrogen generators are used for inerting and blanketing processes, where the primary goal is to prevent oxidation and ensure safety rather than achieving high nitrogen purity. Overall, the global nitrogen generator market is diverse, with both PSA and membrane nitrogen generators catering to different industrial needs. The continuous advancements in technology and the growing demand for efficient and sustainable gas generation solutions are expected to drive the market forward. As industries continue to expand and evolve, the need for reliable and cost-effective nitrogen generators will remain a key factor in the market's growth.

Food & Beverage, Chemical & Petrochemical, Electronics, General Industrial, Others in the Global Nitrogen Generator Market:

The global nitrogen generator market finds extensive usage across various industries, including food and beverage, chemical and petrochemical, electronics, general industrial, and others. In the food and beverage industry, nitrogen generators are used to preserve the freshness and quality of products. Nitrogen gas is used in packaging to displace oxygen, which helps in preventing oxidation and spoilage. This extends the shelf life of perishable goods such as snacks, beverages, and dairy products. Additionally, nitrogen is used in the production of carbonated drinks to maintain the desired level of carbonation and prevent the growth of bacteria. In the chemical and petrochemical industry, nitrogen generators play a crucial role in ensuring safety and efficiency. Nitrogen is used for inerting and blanketing processes, where it is introduced into storage tanks and pipelines to displace oxygen and prevent the risk of explosions or fires. This is particularly important in the handling and storage of flammable and hazardous chemicals. Nitrogen is also used in purging and cleaning processes to remove contaminants and moisture from equipment and pipelines, ensuring the integrity and quality of the products. The electronics industry relies on nitrogen generators for various manufacturing processes. Nitrogen gas is used in soldering and reflow processes to create an inert atmosphere, preventing oxidation and ensuring high-quality solder joints. This is essential for the production of electronic components and circuit boards, where even the slightest contamination can lead to defects and failures. Nitrogen is also used in the production of semiconductors and other electronic devices, where it helps in maintaining a controlled environment and preventing contamination. In general industrial applications, nitrogen generators are used for a wide range of purposes. Nitrogen is used in metal fabrication and welding processes to create an inert atmosphere, preventing oxidation and ensuring high-quality welds. It is also used in the production of plastics and rubber, where it helps in maintaining the desired properties of the materials. Additionally, nitrogen is used in the aerospace and automotive industries for testing and calibration of equipment, as well as in the production of tires and other components. Other industries that utilize nitrogen generators include pharmaceuticals, healthcare, and oil and gas. In the pharmaceutical industry, nitrogen is used to maintain sterile environments and prevent contamination during the production and packaging of drugs. In healthcare, nitrogen is used in cryopreservation and medical gas applications. In the oil and gas industry, nitrogen is used for well stimulation, pressure testing, and pipeline purging. Overall, the global nitrogen generator market serves a diverse range of industries, each with its unique requirements and applications. The versatility and efficiency of nitrogen generators make them an essential component in various industrial processes, contributing to improved safety, quality, and productivity. As industries continue to grow and evolve, the demand for nitrogen generators is expected to increase, driving the market forward.

Global Nitrogen Generator Market Outlook:

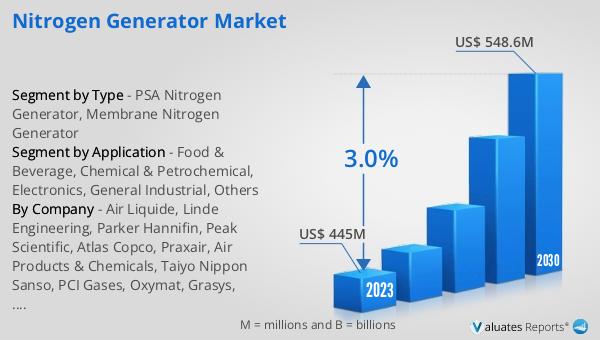

The global nitrogen generator market is anticipated to grow significantly, reaching an estimated value of US$ 548.6 million by 2030, up from US$ 459.5 million in 2024, with a compound annual growth rate (CAGR) of 3.0% between 2024 and 2030. Key players in the market include Peak Scientific, Parker Hannifin, Fizz Dispense Optimization, Air Liquide, Linde Engineering, and Altrad, collectively accounting for approximately 32% of the market share. Europe stands as the largest market for nitrogen generators, holding a share of over 30%. Among the various types of nitrogen generators, PSA (Pressure Swing Adsorption) nitrogen generators are the most prevalent, representing more than 79% of the market. The general industrial sector is the leading application area, with a share exceeding 34%. These statistics highlight the significant role of nitrogen generators in various industries and regions, underscoring their importance in ensuring efficient and reliable nitrogen supply for diverse applications.

| Report Metric | Details |

| Report Name | Nitrogen Generator Market |

| Accounted market size in 2024 | an estimated US$ 459.5 million |

| Forecasted market size in 2030 | US$ 548.6 million |

| CAGR | 3.0% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Air Liquide, Linde Engineering, Parker Hannifin, Peak Scientific, Atlas Copco, Praxair, Air Products & Chemicals, Taiyo Nippon Sanso, PCI Gases, Oxymat, Grasys, Inmatec Gase Technologie, Holtec Gas Systems, Kuraray, MVS Engineering, NOVAIR Noxerior, Sysadvance, Claind, AirSep, Rich, Absoger, On Site Gas Systems, Erredue, Mahler Ags, Isolcell, SMC, Generon, Air Water Bellpearl, South-Tek Systems, Fizz Dispense Optimization, Kofloc, Oxywise, Great Lakes Air, Shandong Gamma Gas Engineering, Titus, SAM GAS Projects, Advance Riken, Proton OnSite, FEDA Nitrogen, General Gas, Burns Machinery, Compressed Gas Technologies, Green Air Supply, Van Amerongen, Zhongrui, PSA Nitrogen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |