What is Global Nitrile Rubber Gaskets Market?

The Global Nitrile Rubber Gaskets Market refers to the worldwide industry focused on the production and distribution of gaskets made from nitrile rubber, also known as NBR (Nitrile Butadiene Rubber). These gaskets are essential components used in various industries due to their excellent resistance to oils, fuels, and other chemicals. Nitrile rubber gaskets are particularly valued for their durability, flexibility, and ability to maintain a tight seal under extreme conditions. They are commonly used in applications where there is a need for a reliable seal to prevent leaks and ensure the proper functioning of machinery and equipment. The market for these gaskets is driven by the increasing demand from sectors such as automotive, aerospace, oil and gas, and healthcare, where the performance and reliability of sealing solutions are critical. As industries continue to expand and modernize, the need for high-quality nitrile rubber gaskets is expected to grow, making this market a vital component of the global industrial landscape.

Standard Nitrile, Special Nitrile in the Global Nitrile Rubber Gaskets Market:

Standard Nitrile and Special Nitrile are two key types of nitrile rubber used in the Global Nitrile Rubber Gaskets Market. Standard Nitrile, also known as Buna-N, is the most commonly used type of nitrile rubber. It is known for its excellent resistance to petroleum-based oils and fuels, making it ideal for use in automotive and industrial applications. Standard Nitrile gaskets are widely used in fuel systems, oil pans, and other components where oil resistance is crucial. They also offer good mechanical properties, such as tensile strength and abrasion resistance, which contribute to their durability and longevity. On the other hand, Special Nitrile refers to nitrile rubber that has been modified or enhanced to provide additional properties or to meet specific requirements. For example, hydrogenated nitrile butadiene rubber (HNBR) is a type of Special Nitrile that offers improved resistance to heat, ozone, and aging compared to Standard Nitrile. This makes HNBR gaskets suitable for use in high-temperature environments and applications where long-term durability is essential. Another example of Special Nitrile is carboxylated nitrile butadiene rubber (XNBR), which has enhanced abrasion and tear resistance, making it ideal for use in dynamic sealing applications such as hydraulic systems and conveyor belts. The choice between Standard Nitrile and Special Nitrile depends on the specific requirements of the application, including the type of fluids being sealed, the operating temperature range, and the mechanical stresses involved. Both types of nitrile rubber offer unique advantages and are used in a wide range of industries to ensure reliable and effective sealing solutions.

Aerospace and Defense, Infrastructure, Medical and Health Care, Oil Industry, Automotive, Others in the Global Nitrile Rubber Gaskets Market:

The usage of Global Nitrile Rubber Gaskets Market spans across various industries, including Aerospace and Defense, Infrastructure, Medical and Health Care, Oil Industry, Automotive, and others. In the Aerospace and Defense sector, nitrile rubber gaskets are used in aircraft fuel systems, hydraulic systems, and other critical components where reliable sealing is essential to ensure safety and performance. These gaskets must withstand extreme temperatures, pressures, and exposure to various chemicals, making nitrile rubber an ideal material. In the Infrastructure sector, nitrile rubber gaskets are used in water and wastewater systems, pipelines, and construction equipment. Their resistance to oils, fuels, and chemicals makes them suitable for sealing joints and preventing leaks in various infrastructure applications. In the Medical and Health Care sector, nitrile rubber gaskets are used in medical devices, laboratory equipment, and pharmaceutical manufacturing. Their chemical resistance and biocompatibility make them suitable for use in environments where hygiene and safety are paramount. In the Oil Industry, nitrile rubber gaskets are used in drilling equipment, pipelines, and refineries. Their ability to withstand harsh chemicals, high pressures, and extreme temperatures makes them essential for ensuring the safe and efficient operation of oil and gas facilities. In the Automotive sector, nitrile rubber gaskets are used in engines, transmissions, and fuel systems. Their resistance to oils and fuels, combined with their durability and flexibility, makes them ideal for use in various automotive applications. Other industries that use nitrile rubber gaskets include food and beverage, electronics, and manufacturing, where reliable sealing solutions are critical for maintaining product quality and operational efficiency. Overall, the versatility and performance of nitrile rubber gaskets make them indispensable in a wide range of applications across multiple industries.

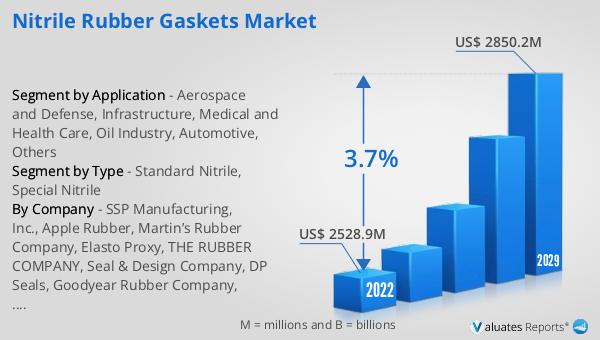

Global Nitrile Rubber Gaskets Market Outlook:

The Global Nitrile Butadiene Rubber (NBR) market is anticipated to grow significantly, reaching an estimated value of US$ 2850.2 million by 2029, up from US$ 2528.9 million in 2022. This growth represents a compound annual growth rate (CAGR) of 3.7% over the forecast period from 2023 to 2029. China stands out as the largest market for NBR, accounting for approximately 37% of the global market share. Following China, Southeast Asia and Europe hold significant shares of about 16% and 15%, respectively. This market outlook highlights the increasing demand for NBR across various regions, driven by its extensive applications in industries such as automotive, oil and gas, and healthcare. The robust growth in these regions underscores the importance of NBR as a critical material for manufacturing high-performance gaskets and seals that meet the stringent requirements of modern industrial applications. As the market continues to expand, manufacturers and suppliers are likely to focus on innovation and quality to meet the evolving needs of their customers and maintain a competitive edge in the global market.

| Report Metric | Details |

| Report Name | Nitrile Rubber Gaskets Market |

| Accounted market size in 2022 | US$ 2528.9 million |

| Forecasted market size in 2029 | US$ 2850.2 million |

| CAGR | 3.7% |

| Base Year | 2022 |

| Forecasted years | 2024 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SSP Manufacturing, Inc., Apple Rubber, Martin’s Rubber Company, Elasto Proxy, THE RUBBER COMPANY, Seal & Design Company, DP Seals, Goodyear Rubber Company, Atlantic Gasket Corporation, Dawn, Custom Rubber, CGR, Satori Seal, Hennig Gasket & Seals, KINDDI, GAOXIN RUBBER&PLASTIC, ERIKS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |