What is Global Nickel-Zinc Ferrite Core Market?

The Global Nickel-Zinc Ferrite Core Market is a specialized segment within the broader electronics and materials industry. Nickel-Zinc Ferrite Cores are magnetic materials composed primarily of nickel, zinc, and iron oxides. These cores are widely used in various electronic applications due to their high magnetic permeability and low electrical conductivity, which make them ideal for minimizing energy losses in high-frequency applications. The market for these cores is driven by their extensive use in transformers, inductors, and various types of electromagnetic interference (EMI) suppression devices. As technology advances and the demand for more efficient electronic components grows, the need for high-performance ferrite cores also increases. This market is characterized by continuous innovation and development to meet the evolving requirements of modern electronic devices. The global reach of this market indicates its significance in supporting the infrastructure of numerous high-tech industries, from consumer electronics to automotive applications.

Laminated Molding, Dry Pressing, Hot Die Casting in the Global Nickel-Zinc Ferrite Core Market:

Laminated Molding, Dry Pressing, and Hot Die Casting are three primary manufacturing techniques used in the production of Nickel-Zinc Ferrite Cores, each with its unique advantages and applications. Laminated Molding involves layering thin sheets of ferrite material and bonding them together under high pressure and temperature. This method is particularly effective for creating cores with complex shapes and high mechanical strength. It is often used in applications where precise magnetic properties are crucial, such as in high-frequency transformers and inductors. Dry Pressing, on the other hand, involves compacting ferrite powder into a desired shape using a high-pressure press. This technique is cost-effective and suitable for mass production, making it ideal for producing standard core shapes used in a wide range of electronic devices. The pressed cores are then sintered at high temperatures to achieve the necessary magnetic properties. Hot Die Casting is a more advanced method that involves injecting molten ferrite material into a mold under high pressure. This process allows for the production of highly intricate and precise core shapes with excellent surface finish and dimensional accuracy. Hot Die Casting is particularly useful for applications requiring high-performance cores with tight tolerances, such as in advanced communication systems and automotive electronics. Each of these manufacturing techniques plays a crucial role in meeting the diverse needs of the Global Nickel-Zinc Ferrite Core Market, ensuring that the final products meet the stringent requirements of various high-tech applications.

Consumer Electronics, Household Appliances, Communication, LED, Automotive, Others in the Global Nickel-Zinc Ferrite Core Market:

The Global Nickel-Zinc Ferrite Core Market finds extensive usage across several key areas, including Consumer Electronics, Household Appliances, Communication, LED, Automotive, and others. In Consumer Electronics, these ferrite cores are essential components in devices such as smartphones, laptops, and tablets, where they help in reducing electromagnetic interference and improving signal integrity. They are also used in power supplies and chargers to enhance energy efficiency and performance. In Household Appliances, Nickel-Zinc Ferrite Cores are used in various electrical components like motors, transformers, and inductors, contributing to the overall efficiency and reliability of appliances such as washing machines, refrigerators, and air conditioners. In the Communication sector, these cores are critical in the manufacturing of antennas, filters, and transformers used in wireless communication devices, ensuring clear signal transmission and reception. The LED industry also benefits from the use of ferrite cores in LED drivers and power supplies, where they help in minimizing energy losses and improving the overall efficiency of LED lighting systems. In the Automotive sector, Nickel-Zinc Ferrite Cores are used in various electronic control units, sensors, and power management systems, playing a vital role in enhancing the performance and reliability of modern vehicles. Additionally, these cores are used in other applications such as industrial machinery, medical devices, and renewable energy systems, where their unique magnetic properties contribute to improved performance and efficiency. The widespread usage of Nickel-Zinc Ferrite Cores across these diverse sectors underscores their importance in modern technology and their role in driving innovation and efficiency in various high-tech applications.

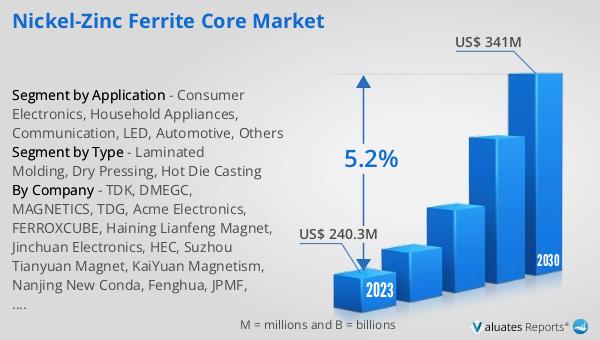

Global Nickel-Zinc Ferrite Core Market Outlook:

The global Nickel-Zinc Ferrite Core market was valued at approximately US$ 240.3 million in 2023 and is projected to grow significantly, reaching an estimated value of US$ 341 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period from 2024 to 2030. The increasing demand for high-performance electronic components across various industries, including consumer electronics, automotive, and communication, is a key driver of this market growth. As technology continues to advance and the need for more efficient and reliable electronic devices grows, the demand for Nickel-Zinc Ferrite Cores is expected to rise correspondingly. This market outlook highlights the robust growth potential of the Nickel-Zinc Ferrite Core market and underscores its critical role in supporting the infrastructure of numerous high-tech industries.

| Report Metric | Details |

| Report Name | Nickel-Zinc Ferrite Core Market |

| Accounted market size in 2023 | US$ 240.3 million |

| Forecasted market size in 2030 | US$ 341 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TDK, DMEGC, MAGNETICS, TDG, Acme Electronics, FERROXCUBE, Haining Lianfeng Magnet, Jinchuan Electronics, HEC, Suzhou Tianyuan Magnet, KaiYuan Magnetism, Nanjing New Conda, Fenghua, JPMF, Hitachi Metals, FDK, Samwha Electronics, TOMITA ELECTRIC, JFE Ferrite, NEC TOKIN, Nippon Ceramic, Feelux |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |