What is Global Nickel Alloy Wires Market?

The Global Nickel Alloy Wires Market is a specialized segment within the broader materials industry, focusing on the production and distribution of wires made from nickel-based alloys. These wires are known for their exceptional resistance to corrosion, high-temperature stability, and mechanical strength, making them suitable for a wide range of industrial applications. Nickel alloy wires are used in various sectors, including aerospace, automotive, electronics, and oil and gas, due to their ability to withstand harsh environments and maintain performance under extreme conditions. The market for these wires is driven by the increasing demand for high-performance materials in advanced manufacturing processes and the growing need for durable and reliable components in critical applications. As industries continue to evolve and seek more efficient and robust materials, the demand for nickel alloy wires is expected to grow, making this market a vital component of the global materials industry.

Nickel Prime Type, Nickel Specialty Type, Others in the Global Nickel Alloy Wires Market:

Nickel alloy wires come in various types, each designed to meet specific requirements and applications. The primary types include Nickel Prime Type, Nickel Specialty Type, and others. Nickel Prime Type wires are typically composed of high-purity nickel and are used in applications where superior corrosion resistance and high-temperature performance are essential. These wires are often employed in the aerospace and aeronautics industries, where materials must withstand extreme conditions and maintain structural integrity. Nickel Specialty Type wires, on the other hand, are alloyed with other elements such as chromium, molybdenum, and iron to enhance specific properties like strength, flexibility, and resistance to oxidation. These specialty wires are used in more demanding applications, such as in the oil and gas industry, where they must endure harsh environments and corrosive substances. Other types of nickel alloy wires include those designed for specific niche applications, such as medical devices and electronic components. These wires are engineered to meet the unique requirements of their respective industries, offering tailored solutions that combine the benefits of nickel with other alloying elements. The versatility and adaptability of nickel alloy wires make them a crucial component in various high-performance applications, driving innovation and efficiency across multiple sectors.

Oil and Gas Industry, Medical Industry, Automotive Industry, Aerospace and Aeronautics Industries, Electronic and Electrical Components, Processing Industry, Others in the Global Nickel Alloy Wires Market:

The usage of Global Nickel Alloy Wires Market spans several critical industries, each benefiting from the unique properties of these materials. In the oil and gas industry, nickel alloy wires are used in drilling equipment, pipelines, and offshore platforms due to their excellent resistance to corrosion and high temperatures. These wires ensure the reliability and longevity of equipment operating in harsh and corrosive environments, reducing maintenance costs and downtime. In the medical industry, nickel alloy wires are utilized in the manufacturing of medical devices, such as stents, pacemakers, and surgical instruments. Their biocompatibility, strength, and resistance to corrosion make them ideal for use in the human body, ensuring patient safety and device durability. The automotive industry also relies on nickel alloy wires for various applications, including exhaust systems, sensors, and electrical components. These wires help improve vehicle performance, reduce emissions, and enhance safety features. In the aerospace and aeronautics industries, nickel alloy wires are used in the construction of aircraft engines, turbines, and structural components. Their ability to withstand extreme temperatures and mechanical stress makes them essential for ensuring the safety and efficiency of aircraft. Electronic and electrical components also benefit from the use of nickel alloy wires, which are used in connectors, resistors, and other critical parts. These wires provide reliable electrical conductivity and resistance to oxidation, ensuring the longevity and performance of electronic devices. In the processing industry, nickel alloy wires are used in heat exchangers, furnaces, and chemical processing equipment. Their resistance to high temperatures and corrosive substances makes them ideal for use in demanding industrial processes. Other applications of nickel alloy wires include their use in the production of consumer goods, such as jewelry and kitchenware, where their aesthetic appeal and durability are highly valued. The diverse applications of nickel alloy wires across multiple industries highlight their importance in modern manufacturing and technology.

Global Nickel Alloy Wires Market Outlook:

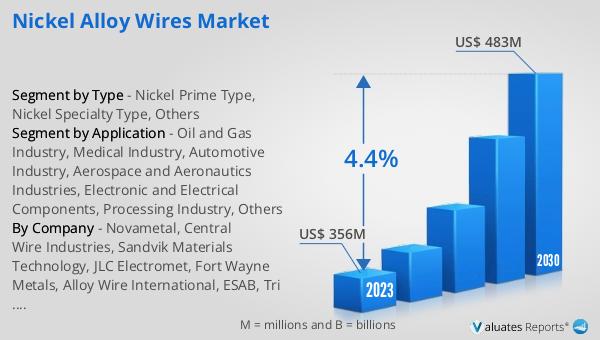

The global Nickel Alloy Wires market is anticipated to grow significantly, with projections indicating it will reach US$ 483 million by 2030, up from an estimated US$ 373 million in 2024, reflecting a compound annual growth rate (CAGR) of 4.4% during the period from 2024 to 2030. This growth is driven by the increasing demand for high-performance materials across various industries. Major manufacturers in this market include Novametal, Central Wire Industries, and Sandvik Materials Technology, which accounted for 12.31%, 9.87%, and 9.30% of the market revenue in 2019, respectively. These companies are at the forefront of innovation and production, providing high-quality nickel alloy wires that meet the stringent requirements of their customers. The market's expansion is supported by advancements in manufacturing technologies, increasing industrialization, and the growing need for durable and reliable materials in critical applications. As industries continue to evolve and seek more efficient and robust materials, the demand for nickel alloy wires is expected to grow, making this market a vital component of the global materials industry.

| Report Metric | Details |

| Report Name | Nickel Alloy Wires Market |

| Accounted market size in 2024 | an estimated US$ 373 million |

| Forecasted market size in 2030 | US$ 483 million |

| CAGR | 4.4% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Novametal, Central Wire Industries, Sandvik Materials Technology, JLC Electromet, Fort Wayne Metals, Alloy Wire International, ESAB, Tri Star Metals, Knight Precision Wire, Raajratna, California Fine Wire, Elektrisola, Radcliff Wire, Wintwire |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |