What is Global Injection Molding Machinery Market?

The Global Injection Molding Machinery Market refers to the worldwide industry involved in the production and sale of machines used for injection molding. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. This market encompasses a variety of machinery types, including hydraulic, electric, and hybrid machines, each designed to meet specific production needs. The market is driven by the demand for high-quality, precision-engineered plastic products across various industries such as automotive, electronics, packaging, and consumer goods. Technological advancements, increasing automation, and the need for energy-efficient solutions are key factors propelling the growth of this market. Companies in this sector are continually innovating to offer machines that provide higher efficiency, better performance, and lower operational costs. The market is highly competitive, with numerous players striving to gain a larger share by offering advanced features and superior customer service. The global reach of this market means that it is influenced by economic conditions, regulatory changes, and technological trends across different regions.

Clamping Force: Below 250T, Clamping Force: 250-650T, Clamping Force: Above 650T in the Global Injection Molding Machinery Market:

In the Global Injection Molding Machinery Market, clamping force is a critical parameter that determines the machine's capability to hold the mold closed during the injection process. Machines with a clamping force below 250 tons (250T) are typically used for producing small to medium-sized parts. These machines are highly favored in industries where precision and intricate detailing are paramount, such as electronics, medical devices, and small consumer goods. Their compact size and lower operational costs make them ideal for manufacturers looking to produce high-quality parts in smaller volumes. On the other hand, machines with a clamping force ranging from 250 to 650 tons (250-650T) are versatile and can handle a broader range of applications. These machines are commonly used in the automotive industry, where they produce medium-sized components like dashboards, bumpers, and interior trims. The balance between power and flexibility makes them suitable for manufacturers who need to switch between different types of products without compromising on quality or efficiency. Machines with a clamping force above 650 tons (650T) are designed for heavy-duty applications and are capable of producing large, complex parts. These machines are essential in industries such as automotive, where they are used to manufacture large components like car body panels and structural parts. They are also used in the production of large household appliances, industrial containers, and other bulky items. The high clamping force ensures that the mold remains securely closed during the injection process, preventing defects and ensuring the production of high-quality parts. Despite their higher operational costs, these machines are indispensable for manufacturers who require robust and reliable machinery to produce large volumes of heavy-duty parts. The choice of clamping force depends on various factors, including the size and complexity of the parts being produced, the material used, and the production volume. Manufacturers must carefully consider these factors to select the appropriate machine that meets their specific needs while optimizing production efficiency and cost-effectiveness.

General Plastics Industry, Automobile Industry, Home Appliance Industry, Other Industries in the Global Injection Molding Machinery Market:

The Global Injection Molding Machinery Market finds extensive usage across various industries, each with its unique requirements and applications. In the general plastics industry, these machines are used to produce a wide range of products, from simple items like plastic bottles and containers to more complex components like gears and housings. The versatility of injection molding machines allows manufacturers to produce high-quality plastic parts with precision and consistency, making them indispensable in this industry. In the automobile industry, injection molding machines play a crucial role in the production of various components, including dashboards, bumpers, interior trims, and engine parts. The ability to produce lightweight, durable, and high-precision parts is essential for automotive manufacturers looking to improve fuel efficiency and meet stringent safety standards. The home appliance industry also relies heavily on injection molding machinery for the production of components such as refrigerator liners, washing machine parts, and vacuum cleaner housings. The demand for aesthetically pleasing and functional household appliances drives the need for high-quality injection molded parts. Other industries, such as electronics, medical devices, and packaging, also benefit from the capabilities of injection molding machines. In the electronics industry, these machines are used to produce components like connectors, housings, and circuit boards, where precision and reliability are critical. The medical device industry requires injection molding machines to manufacture components like syringes, surgical instruments, and diagnostic equipment, where hygiene and accuracy are paramount. The packaging industry uses these machines to produce a variety of containers, caps, and closures, ensuring that products are safely and securely packaged. The adaptability and efficiency of injection molding machines make them a valuable asset across these diverse industries, driving innovation and enabling the production of high-quality products.

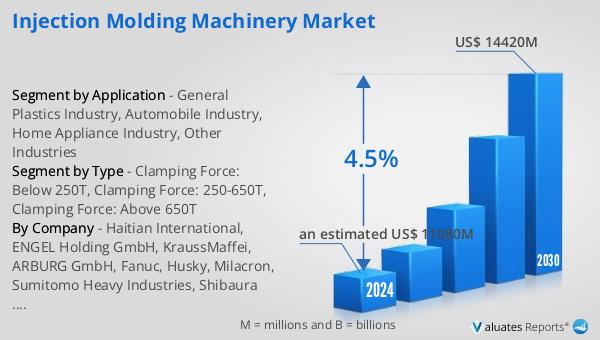

Global Injection Molding Machinery Market Outlook:

The global Injection Molding Machinery market is anticipated to grow significantly, reaching an estimated value of US$ 14420 million by 2030, up from US$ 11080 million in 2024, with a compound annual growth rate (CAGR) of 4.5% during the period from 2024 to 2030. Haitian International stands out as the world's largest manufacturer of injection molding machines, having sold over 32,000 units in 2019, which accounted for 22% of the global market. The Asia Pacific region is the largest consumer, holding nearly 55% of the consumption market share in 2019. When analyzing product specifications, small and medium-sized models with a clamping force of up to 650 tons dominate the market, occupying more than 90% of the market share. In terms of application, the general plastics industry, automobile industry, and household appliances industry hold significant market shares, respectively.

| Report Metric | Details |

| Report Name | Injection Molding Machinery Market |

| Accounted market size in 2024 | an estimated US$ 11080 million |

| Forecasted market size in 2030 | US$ 14420 million |

| CAGR | 4.5% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Haitian International, ENGEL Holding GmbH, KraussMaffei, ARBURG GmbH, Fanuc, Husky, Milacron, Sumitomo Heavy Industries, Shibaura Machine, Nissei Plastic, JSW Plastics Machinery, Wittmann Battenfeld, Chen Hsong Injection Molding Machinery, Toyo, Guangdong Yizumi Precision Machinery Co.,Ltd., UBE Machinery, L.K. Technology Holdings Limited, Cosmos Machinery, TEDERIC Machinery, Windsor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |