What is Global 1,6-diisocyanate (HDI) Market?

The Global 1,6-diisocyanate (HDI) Market is a specialized segment within the broader chemical industry, focusing on the production and application of 1,6-hexamethylene diisocyanate (HDI). HDI is a crucial raw material used primarily in the manufacture of polyurethane products. These products are highly valued for their durability, flexibility, and resistance to chemicals and abrasion. HDI is particularly significant in the production of coatings, adhesives, and inks, which are used across various industries including automotive, construction, and electronics. The market for HDI is driven by the increasing demand for high-performance materials that can withstand harsh environmental conditions. Additionally, advancements in technology and manufacturing processes have made HDI more accessible and cost-effective, further fueling its adoption. The global HDI market is characterized by a competitive landscape with several key players striving to innovate and expand their product offerings. This market is also influenced by regulatory standards and environmental considerations, as HDI production and usage must comply with safety and environmental regulations. Overall, the Global 1,6-diisocyanate (HDI) Market plays a vital role in the development of advanced materials that meet the evolving needs of various industries.

0.995, Others in the Global 1,6-diisocyanate (HDI) Market:

The Global 1,6-diisocyanate (HDI) Market encompasses a variety of product types, including the 0.995 grade and others. The 0.995 grade HDI is known for its high purity level, making it ideal for applications that require superior performance and minimal impurities. This grade is often used in high-end coatings and adhesives where quality and consistency are paramount. The high purity level ensures that the end products have excellent mechanical properties, such as enhanced durability and resistance to wear and tear. On the other hand, the "others" category includes HDI products with varying purity levels and formulations tailored for specific applications. These products may be used in less demanding applications where cost-effectiveness is a priority. The versatility of HDI allows it to be customized to meet the specific needs of different industries. For instance, in the automotive industry, HDI-based coatings are used to provide a durable and aesthetically pleasing finish to vehicles. In the construction industry, HDI adhesives are used to bond various materials, providing strong and long-lasting connections. The electronics industry also benefits from HDI, as it is used in the production of protective coatings for electronic components, ensuring their longevity and reliability. The market for HDI is influenced by several factors, including technological advancements, regulatory standards, and environmental considerations. Manufacturers are continually investing in research and development to improve the performance and sustainability of HDI products. This includes developing eco-friendly formulations that reduce the environmental impact of HDI production and usage. Additionally, regulatory standards play a crucial role in shaping the market, as manufacturers must comply with safety and environmental regulations. This has led to the development of safer and more sustainable HDI products that meet the stringent requirements of various industries. Overall, the Global 1,6-diisocyanate (HDI) Market is a dynamic and evolving segment that offers a wide range of products to meet the diverse needs of different industries.

Polyurethane Coatings, Adhesive, Inks, Others in the Global 1,6-diisocyanate (HDI) Market:

The usage of Global 1,6-diisocyanate (HDI) Market products spans several key areas, including polyurethane coatings, adhesives, inks, and others. Polyurethane coatings are one of the primary applications of HDI, valued for their excellent protective properties. These coatings are used in various industries, including automotive, aerospace, and construction, to provide a durable and resistant finish. HDI-based polyurethane coatings offer superior resistance to chemicals, abrasion, and UV radiation, making them ideal for harsh environments. In the automotive industry, these coatings are used to protect vehicle exteriors from corrosion and wear, ensuring a long-lasting and aesthetically pleasing finish. In the aerospace industry, HDI-based coatings are used to protect aircraft surfaces from extreme weather conditions and mechanical stress. In the construction industry, these coatings are applied to buildings and infrastructure to enhance their durability and longevity. Adhesives are another significant application of HDI, providing strong and reliable bonds for various materials. HDI-based adhesives are used in industries such as construction, automotive, and electronics, where strong and durable bonds are essential. These adhesives offer excellent adhesion properties, ensuring that materials remain securely bonded even under challenging conditions. In the construction industry, HDI-based adhesives are used to bond materials such as wood, metal, and plastic, providing strong and long-lasting connections. In the automotive industry, these adhesives are used in the assembly of vehicles, ensuring that components remain securely attached. In the electronics industry, HDI-based adhesives are used to bond electronic components, ensuring their reliability and longevity. Inks are another important application of HDI, used in the production of high-quality printing inks. HDI-based inks offer excellent adhesion properties, ensuring that prints remain clear and vibrant even under challenging conditions. These inks are used in various industries, including packaging, textiles, and electronics, where high-quality prints are essential. In the packaging industry, HDI-based inks are used to print labels and packaging materials, ensuring that prints remain clear and legible. In the textiles industry, these inks are used to print designs on fabrics, ensuring that prints remain vibrant and durable. In the electronics industry, HDI-based inks are used to print circuit boards and other electronic components, ensuring their reliability and performance. Overall, the usage of Global 1,6-diisocyanate (HDI) Market products in polyurethane coatings, adhesives, inks, and other applications highlights the versatility and importance of HDI in various industries.

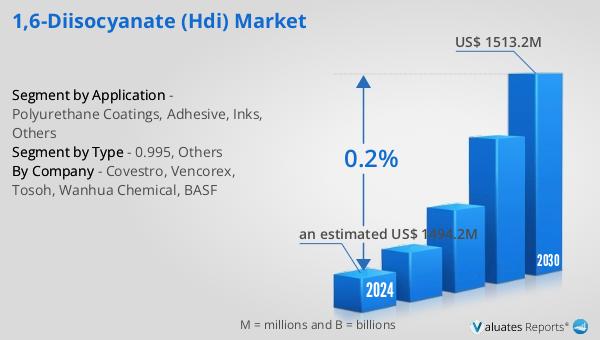

Global 1,6-diisocyanate (HDI) Market Outlook:

The global 1,6-diisocyanate (HDI) market is anticipated to grow from an estimated value of US$ 1494.2 million in 2024 to approximately US$ 1513.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 0.2% over the forecast period. This modest growth rate indicates a stable demand for HDI products across various industries. The market's steady expansion can be attributed to the ongoing need for high-performance materials that offer durability, flexibility, and resistance to harsh environmental conditions. Despite the relatively low CAGR, the market's value underscores the importance of HDI in the production of advanced materials used in coatings, adhesives, and inks. The competitive landscape of the HDI market is characterized by continuous innovation and development, with key players striving to enhance the performance and sustainability of their products. Regulatory standards and environmental considerations also play a significant role in shaping the market, as manufacturers must comply with stringent safety and environmental regulations. This has led to the development of safer and more sustainable HDI products that meet the evolving needs of various industries. Overall, the global 1,6-diisocyanate (HDI) market is poised for steady growth, driven by the ongoing demand for high-performance materials and the continuous efforts of manufacturers to innovate and improve their product offerings.

| Report Metric | Details |

| Report Name | 1,6-diisocyanate (HDI) Market |

| Accounted market size in 2024 | an estimated US$ 1494.2 million |

| Forecasted market size in 2030 | US$ 1513.2 million |

| CAGR | 0.2% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Covestro, Vencorex, Tosoh, Wanhua Chemical, BASF |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |