What is Global Industrial Smoke Extraction Motor Market?

The Global Industrial Smoke Extraction Motor Market is a specialized segment within the broader industrial motor market, focusing on motors designed to extract smoke and fumes from industrial environments. These motors are crucial for maintaining air quality and ensuring the safety of workers in various industrial settings. They are typically used in factories, warehouses, and other large facilities where smoke and fumes can accumulate due to manufacturing processes, chemical reactions, or accidental fires. The primary function of these motors is to drive smoke extraction systems, which include fans and ducts that remove contaminated air and replace it with fresh air. This process helps to prevent the buildup of toxic gases and reduces the risk of fire spreading. The market for these motors is driven by stringent safety regulations, increasing awareness about workplace safety, and the need for efficient ventilation systems in industrial settings. As industries continue to grow and expand, the demand for reliable and efficient smoke extraction motors is expected to rise, making this a vital component of industrial safety and environmental control systems.

200 °C Class, 250 °C Class, 300 °C Class, 400 °C Class in the Global Industrial Smoke Extraction Motor Market:

In the Global Industrial Smoke Extraction Motor Market, motors are classified based on their temperature resistance capabilities, which are crucial for their performance in high-heat environments. The 200 °C Class motors are designed to operate efficiently at temperatures up to 200 degrees Celsius. These motors are typically used in environments where moderate heat is generated, such as in certain manufacturing processes or smaller industrial settings. They provide a balance between cost and performance, making them suitable for a wide range of applications. The 250 °C Class motors can withstand temperatures up to 250 degrees Celsius and are used in more demanding environments where higher heat levels are present. These motors are often found in larger factories or facilities where more intense manufacturing processes take place. The 300 °C Class motors are designed for even higher temperature environments, up to 300 degrees Celsius. These motors are essential in industries where extreme heat is a constant factor, such as in metalworking or chemical processing plants. Finally, the 400 °C Class motors are the most robust, capable of operating in environments with temperatures up to 400 degrees Celsius. These motors are used in the most extreme industrial settings, where safety and reliability are paramount. Each class of motor is designed to meet specific needs, ensuring that smoke extraction systems can operate effectively regardless of the heat levels present in the environment. The classification of these motors based on temperature resistance is a critical factor in their selection and application, as it ensures that the motors can perform reliably under the specific conditions they will encounter. This classification also helps in standardizing the motors, making it easier for industries to choose the right motor for their specific needs. The development and improvement of these motors are driven by advancements in materials and engineering, which allow for better heat resistance and more efficient operation. As industries continue to evolve and face new challenges, the demand for high-performance smoke extraction motors that can operate in extreme conditions is expected to grow. This growth will likely lead to further innovations in motor design and technology, enhancing the overall efficiency and safety of industrial smoke extraction systems.

Factory, Storehouse, Other in the Global Industrial Smoke Extraction Motor Market:

The usage of Global Industrial Smoke Extraction Motors is widespread across various industrial settings, including factories, storehouses, and other facilities. In factories, these motors play a crucial role in maintaining air quality and ensuring the safety of workers. Factories often involve processes that generate significant amounts of smoke, fumes, and other airborne contaminants. Smoke extraction motors drive the ventilation systems that remove these harmful substances, preventing them from accumulating and posing health risks to workers. These motors are essential in industries such as metalworking, chemical processing, and manufacturing, where the production processes can generate high levels of smoke and fumes. In storehouses, smoke extraction motors are equally important. Storehouses often store large quantities of goods, some of which may be flammable or produce fumes. In the event of a fire, smoke extraction motors help to quickly remove smoke, reducing the risk of the fire spreading and making it easier for fire suppression systems to work effectively. They also help to maintain air quality in the storehouse, ensuring that workers can operate in a safe environment. Other facilities that benefit from the use of smoke extraction motors include commercial buildings, hospitals, and public spaces. In commercial buildings, these motors are used to maintain air quality and ensure the safety of occupants in the event of a fire. Hospitals use smoke extraction motors to protect patients and staff from the harmful effects of smoke and fumes, ensuring a safe and healthy environment. Public spaces such as shopping malls, airports, and train stations also rely on smoke extraction motors to maintain air quality and ensure the safety of visitors. The versatility and importance of smoke extraction motors in these various settings highlight their critical role in industrial safety and environmental control. As industries and facilities continue to grow and evolve, the demand for efficient and reliable smoke extraction motors is expected to increase, driving further advancements in motor technology and design.

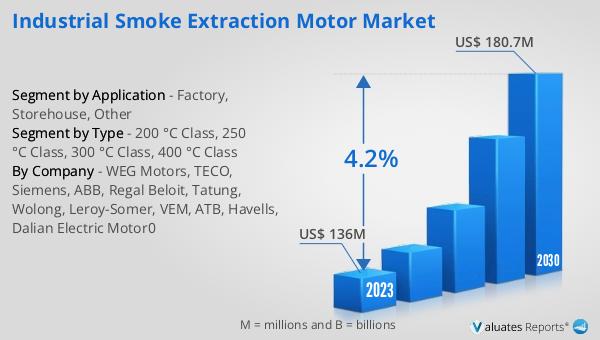

Global Industrial Smoke Extraction Motor Market Outlook:

The global Industrial Smoke Extraction Motor market was valued at US$ 136 million in 2023 and is anticipated to reach US$ 180.7 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing industrial activities and the need for enhanced safety measures in workplaces. The rising awareness about the importance of air quality and the implementation of stringent safety regulations are key factors contributing to this growth. As industries expand and new facilities are established, the demand for efficient smoke extraction systems, powered by reliable motors, is expected to rise. This growth is also supported by technological advancements in motor design and materials, which enhance their performance and durability in high-heat environments. The market's expansion reflects the critical role that smoke extraction motors play in ensuring the safety and well-being of workers in various industrial settings.

| Report Metric | Details |

| Report Name | Industrial Smoke Extraction Motor Market |

| Accounted market size in 2023 | US$ 136 million |

| Forecasted market size in 2030 | US$ 180.7 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | WEG Motors, TECO, Siemens, ABB, Regal Beloit, Tatung, Wolong, Leroy-Somer, VEM, ATB, Havells, Dalian Electric Motor0 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |