What is Global Fuel Quality Sensor Market?

The Global Fuel Quality Sensor Market is a specialized segment within the broader sensor market, focusing on devices that measure and monitor the quality of fuel used in various applications. These sensors are crucial for ensuring that engines and machinery operate efficiently and without damage, as poor fuel quality can lead to significant performance issues and maintenance costs. The market encompasses a range of sensor types, including NIR (Near-Infrared) sensors, tuning fork sensors, and other advanced technologies. These sensors are employed in diverse industries such as automotive, construction machinery, generators, and maritime vessels. The growing emphasis on fuel efficiency and stringent environmental regulations are key drivers for the adoption of fuel quality sensors globally. As industries strive to optimize fuel usage and reduce emissions, the demand for accurate and reliable fuel quality sensors is expected to rise. The market is characterized by technological advancements and innovations aimed at enhancing sensor accuracy, durability, and integration capabilities.

NIR Sensors, Tuning Fork Sensors, Other in the Global Fuel Quality Sensor Market:

NIR (Near-Infrared) sensors are a prominent type of fuel quality sensor used in the Global Fuel Quality Sensor Market. These sensors operate by emitting near-infrared light and measuring the absorption of this light by the fuel. The absorption spectrum provides detailed information about the fuel's composition, including the presence of contaminants and the overall quality. NIR sensors are highly valued for their precision and ability to provide real-time data, making them ideal for applications where immediate feedback is crucial. Tuning fork sensors, on the other hand, utilize the principle of resonance frequency to detect changes in fuel quality. These sensors consist of a pair of tuning forks that vibrate at a specific frequency. When fuel passes through the sensor, any changes in the fuel's properties, such as density or viscosity, alter the vibration frequency. This change is then measured and analyzed to determine the fuel quality. Tuning fork sensors are known for their robustness and reliability, making them suitable for harsh environments. Other types of fuel quality sensors include capacitive sensors, which measure changes in the dielectric constant of the fuel, and optical sensors, which use light scattering techniques to assess fuel quality. Each type of sensor has its unique advantages and is chosen based on the specific requirements of the application. The integration of these sensors into fuel systems helps in maintaining optimal engine performance, reducing emissions, and preventing potential damage caused by poor fuel quality.

Automotive, Construction Machinery, Generator, Ship, Other in the Global Fuel Quality Sensor Market:

The usage of Global Fuel Quality Sensor Market spans across various sectors, including automotive, construction machinery, generators, ships, and other industries. In the automotive sector, fuel quality sensors play a critical role in ensuring that vehicles operate efficiently and meet stringent emission standards. These sensors help in detecting contaminants and variations in fuel composition, which can affect engine performance and longevity. By providing real-time data on fuel quality, these sensors enable automotive manufacturers and service providers to optimize fuel injection systems, improve combustion efficiency, and reduce harmful emissions. In construction machinery, fuel quality sensors are essential for maintaining the reliability and performance of heavy-duty equipment. Construction machinery often operates in challenging environments where fuel contamination is a common issue. Fuel quality sensors help in identifying and mitigating the impact of poor fuel quality, thereby reducing downtime and maintenance costs. For generators, especially those used in critical applications such as hospitals and data centers, fuel quality sensors ensure a consistent and reliable power supply. These sensors monitor the fuel quality to prevent generator failures caused by contaminated or degraded fuel. In the maritime industry, fuel quality sensors are used to comply with international regulations on sulfur content and other fuel parameters. Ships rely on these sensors to ensure that the fuel used meets the required standards, thereby avoiding penalties and ensuring efficient engine operation. Other industries, such as aviation and agriculture, also benefit from the use of fuel quality sensors to enhance the performance and reliability of their equipment. Overall, the adoption of fuel quality sensors across these sectors underscores their importance in maintaining operational efficiency, reducing environmental impact, and ensuring compliance with regulatory standards.

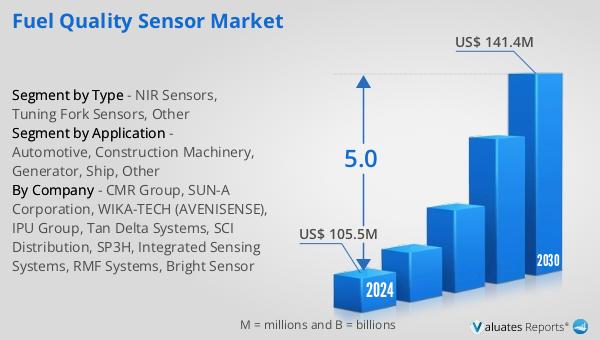

Global Fuel Quality Sensor Market Outlook:

The global Fuel Quality Sensor market is anticipated to grow significantly, reaching an estimated value of US$ 141.4 million by 2030, up from US$ 105.5 million in 2024, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. The market is dominated by the top ten manufacturers, who collectively hold a market share exceeding 37%. Europe stands out as the largest producer of fuel quality sensors, accounting for over 38% of the market share, followed by Japan and North America. In terms of application, the automotive sector emerges as the largest segment, with a market share exceeding 30%. This growth is driven by the increasing demand for fuel-efficient vehicles and the implementation of stringent emission regulations across various regions. The advancements in sensor technology and the integration of these sensors into modern fuel systems are also contributing to the market's expansion. As industries continue to prioritize fuel efficiency and environmental sustainability, the demand for high-quality fuel sensors is expected to rise, further propelling the market growth.

| Report Metric | Details |

| Report Name | Fuel Quality Sensor Market |

| Accounted market size in 2024 | an estimated US$ 105.5 million |

| Forecasted market size in 2030 | US$ 141.4 million |

| CAGR | 5.0% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | CMR Group, SUN-A Corporation, WIKA-TECH (AVENISENSE), IPU Group, Tan Delta Systems, SCI Distribution, SP3H, Integrated Sensing Systems, RMF Systems, Bright Sensor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |