What is Global Automotive Dry Film Lubricants Market?

The Global Automotive Dry Film Lubricants Market refers to the industry focused on the production and distribution of specialized lubricants used in the automotive sector. These lubricants are unique because they are applied in a dry form, unlike traditional liquid lubricants. They are designed to reduce friction, wear, and corrosion on various automotive components, enhancing the performance and longevity of vehicles. Dry film lubricants are particularly useful in extreme conditions where traditional lubricants might fail, such as high temperatures, heavy loads, or environments with significant dust and debris. They are used in various parts of vehicles, including engines, transmissions, and braking systems, to ensure smooth operation and reduce maintenance needs. The market for these lubricants is driven by the increasing demand for high-performance vehicles, advancements in automotive technology, and the need for more efficient and durable lubrication solutions. As the automotive industry continues to evolve, the role of dry film lubricants becomes increasingly important in maintaining vehicle reliability and performance.

Polytetrafluoroethylene (PTFE), Molybdenum disulfide (MoS2), Tungsten Disulfide, Boron Nitride, Graphite, Others in the Global Automotive Dry Film Lubricants Market:

Polytetrafluoroethylene (PTFE), Molybdenum disulfide (MoS2), Tungsten Disulfide, Boron Nitride, Graphite, and other materials are key components in the Global Automotive Dry Film Lubricants Market. PTFE, commonly known as Teflon, is renowned for its low friction and high-temperature resistance, making it ideal for applications where smooth, long-lasting lubrication is required. It is often used in engine components and other high-stress areas. Molybdenum disulfide (MoS2) is another critical material, known for its excellent lubricating properties under extreme pressure and temperature conditions. It is frequently used in heavy-duty applications such as gears and bearings. Tungsten Disulfide is similar to MoS2 but offers even better performance in terms of reducing friction and wear, making it suitable for high-performance and racing vehicles. Boron Nitride, often referred to as "white graphite," provides excellent thermal conductivity and electrical insulation, making it useful in electronic components and other specialized automotive parts. Graphite itself is a well-known lubricant, valued for its ability to withstand high temperatures and provide consistent lubrication over long periods. It is commonly used in brake systems and other high-heat environments. Other materials used in dry film lubricants include various polymers and composite materials that offer unique properties tailored to specific automotive applications. These materials are selected based on their ability to provide reliable lubrication under the demanding conditions found in modern vehicles. The combination of these advanced materials ensures that dry film lubricants can meet the diverse needs of the automotive industry, from everyday passenger cars to high-performance sports cars and heavy-duty commercial vehicles.

Passenger Vehicles, Light Commercial Vehicle, Heavy Commercial Vehicle in the Global Automotive Dry Film Lubricants Market:

The usage of Global Automotive Dry Film Lubricants Market spans across various types of vehicles, including passenger vehicles, light commercial vehicles, and heavy commercial vehicles. In passenger vehicles, dry film lubricants are used to enhance the performance and longevity of critical components such as engines, transmissions, and braking systems. These lubricants help reduce friction and wear, leading to smoother operation and reduced maintenance costs. They are particularly beneficial in high-performance cars where the demands on lubrication are greater. In light commercial vehicles, which are often used for delivery and transportation purposes, dry film lubricants play a crucial role in ensuring reliability and efficiency. These vehicles typically operate under varying loads and conditions, and the use of dry film lubricants helps maintain consistent performance and reduce the risk of component failure. In heavy commercial vehicles, such as trucks and buses, the demands on lubrication are even more significant due to the heavy loads and long operating hours. Dry film lubricants are essential in these vehicles to prevent wear and tear on critical components, reduce downtime, and extend the lifespan of the vehicle. They are used in various parts of the vehicle, including the engine, transmission, and braking systems, to ensure smooth and reliable operation. The use of dry film lubricants in these different types of vehicles highlights their versatility and importance in the automotive industry. By providing reliable lubrication under a wide range of conditions, these lubricants help improve vehicle performance, reduce maintenance costs, and enhance overall reliability.

Global Automotive Dry Film Lubricants Market Outlook:

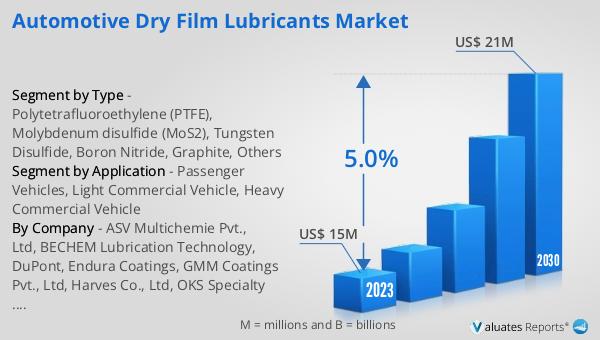

The global Automotive Dry Film Lubricants market was valued at US$ 15 million in 2023 and is anticipated to reach US$ 21 million by 2030, witnessing a CAGR of 5.0% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-performance lubrication solutions in the automotive industry. As vehicles become more advanced and the demands on their components grow, the need for reliable and efficient lubrication becomes more critical. Dry film lubricants offer several advantages over traditional liquid lubricants, including better performance under extreme conditions, reduced friction and wear, and longer-lasting protection. These benefits are driving the adoption of dry film lubricants across various types of vehicles, from passenger cars to heavy commercial vehicles. The market's growth is also supported by advancements in lubricant technology and the development of new materials that offer improved performance and durability. As the automotive industry continues to evolve, the role of dry film lubricants in ensuring vehicle reliability and performance is expected to become even more significant.

| Report Metric | Details |

| Report Name | Automotive Dry Film Lubricants Market |

| Accounted market size in 2023 | US$ 15 million |

| Forecasted market size in 2030 | US$ 21 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASV Multichemie Pvt., Ltd, BECHEM Lubrication Technology, DuPont, Endura Coatings, GMM Coatings Pvt., Ltd, Harves Co., Ltd, OKS Specialty Lubricants LLC, Poeton Industries Limited, The Chemours Company, Vitracoat America Inc, Whitford Corporation, Whitmore Manufacturing Company, Sun Coating Company, Miller-Stephenson |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |