What is Global Aluminum Honeycomb Core for Aircraft and Aerospace Market?

The Global Aluminum Honeycomb Core for Aircraft and Aerospace Market refers to the specialized segment of the aerospace industry that focuses on the production and application of aluminum honeycomb cores. These cores are lightweight, strong, and highly efficient materials used in various aerospace components. The honeycomb structure, which resembles the hexagonal pattern found in natural honeycombs, provides exceptional strength-to-weight ratios, making it ideal for use in aircraft and spacecraft. The market encompasses the manufacturing, distribution, and utilization of these cores in different aerospace applications, including aircraft components, space and satellite components, and rocket components. The demand for aluminum honeycomb cores is driven by the need for lightweight materials that can enhance fuel efficiency, reduce emissions, and improve overall performance in the aerospace sector. The market is characterized by continuous innovation and advancements in material science to meet the stringent requirements of the aerospace industry.

5052 Aluminum Alloy, 5056 Aluminum Alloy in the Global Aluminum Honeycomb Core for Aircraft and Aerospace Market:

5052 Aluminum Alloy and 5056 Aluminum Alloy are two prominent materials used in the Global Aluminum Honeycomb Core for Aircraft and Aerospace Market. The 5052 Aluminum Alloy is known for its excellent corrosion resistance, high fatigue strength, and good weldability. It is commonly used in applications where these properties are critical, such as in the construction of aircraft fuel tanks, hydraulic tubes, and marine environments. The alloy's ability to withstand harsh conditions makes it a preferred choice for aerospace applications that require durability and reliability. On the other hand, the 5056 Aluminum Alloy is recognized for its high strength and excellent corrosion resistance, particularly in marine and industrial environments. This alloy is often used in the manufacturing of rivets, screws, and other fasteners that are essential in aerospace construction. The combination of these two alloys in the production of aluminum honeycomb cores provides a balance of strength, durability, and lightweight properties, making them ideal for various aerospace applications. The honeycomb structure, when made from these alloys, offers superior mechanical performance, including high compressive strength and energy absorption capabilities. This makes them suitable for use in critical aerospace components where weight reduction and structural integrity are paramount. The continuous development and optimization of these alloys contribute to the advancement of the Global Aluminum Honeycomb Core for Aircraft and Aerospace Market, ensuring that the materials meet the evolving demands of the aerospace industry.

Aircraft Components, Space and Satellite Components, Rocket Components, Others in the Global Aluminum Honeycomb Core for Aircraft and Aerospace Market:

The usage of Global Aluminum Honeycomb Core for Aircraft and Aerospace Market spans across various critical areas, including Aircraft Components, Space and Satellite Components, Rocket Components, and others. In Aircraft Components, aluminum honeycomb cores are extensively used in the construction of aircraft fuselage, wings, and control surfaces. The lightweight and high-strength properties of the honeycomb structure help in reducing the overall weight of the aircraft, leading to improved fuel efficiency and reduced operational costs. Additionally, the cores provide excellent impact resistance and energy absorption, enhancing the safety and durability of the aircraft. In Space and Satellite Components, aluminum honeycomb cores are utilized in the construction of satellite panels, reflectors, and other structural components. The lightweight nature of the honeycomb cores is crucial in space applications, where every gram counts. The cores also offer high thermal conductivity, which is essential for managing the extreme temperatures encountered in space. For Rocket Components, aluminum honeycomb cores are used in the construction of rocket fairings, interstages, and other structural elements. The high strength-to-weight ratio of the honeycomb cores ensures that the rockets can withstand the intense forces and vibrations during launch and flight. Additionally, the cores provide excellent thermal insulation, protecting sensitive components from the extreme heat generated during re-entry. Other applications of aluminum honeycomb cores in the aerospace market include the construction of UAVs (Unmanned Aerial Vehicles), drones, and other advanced aerospace systems. The versatility and superior performance of aluminum honeycomb cores make them an indispensable material in the aerospace industry, driving continuous innovation and development in this market.

Global Aluminum Honeycomb Core for Aircraft and Aerospace Market Outlook:

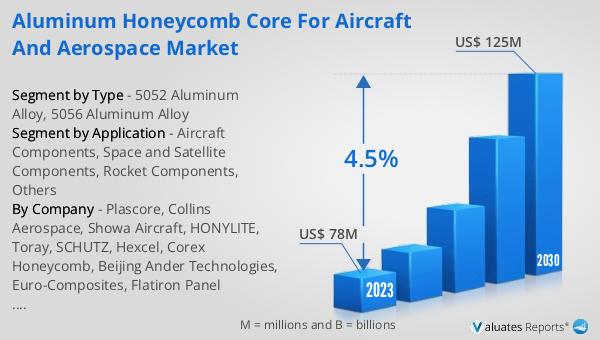

The global Aluminum Honeycomb Core for Aircraft and Aerospace market was valued at US$ 78 million in 2023 and is anticipated to reach US$ 125 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This growth reflects the increasing demand for lightweight and high-strength materials in the aerospace industry. The aluminum honeycomb core market is driven by the need for materials that can enhance fuel efficiency, reduce emissions, and improve overall performance in aircraft and aerospace applications. The market's expansion is also fueled by continuous advancements in material science and manufacturing technologies, which enable the production of more efficient and cost-effective honeycomb cores. The growing adoption of aluminum honeycomb cores in various aerospace applications, including aircraft components, space and satellite components, and rocket components, further contributes to the market's growth. As the aerospace industry continues to evolve, the demand for innovative materials like aluminum honeycomb cores is expected to rise, driving the market's expansion in the coming years.

| Report Metric | Details |

| Report Name | Aluminum Honeycomb Core for Aircraft and Aerospace Market |

| Accounted market size in 2023 | US$ 78 million |

| Forecasted market size in 2030 | US$ 125 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Plascore, Collins Aerospace, Showa Aircraft, HONYLITE, Toray, SCHUTZ, Hexcel, Corex Honeycomb, Beijing Ander Technologies, Euro-Composites, Flatiron Panel Products, Lasermation, Jiaxing Joybusiness, Haxcore |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |