What is Global Aerospace Grade Aramid Fiber Honeycomb Market?

The Global Aerospace Grade Aramid Fiber Honeycomb Market refers to the industry focused on producing and utilizing aramid fiber honeycomb materials specifically designed for aerospace applications. Aramid fibers, known for their exceptional strength and heat resistance, are woven into a honeycomb structure to create lightweight yet incredibly strong materials. These honeycomb structures are used extensively in the aerospace industry to manufacture components that require high strength-to-weight ratios, such as aircraft interiors, control surfaces, and structural panels. The market encompasses the entire supply chain, from raw material suppliers to manufacturers and end-users, including both civil and military aviation sectors. The demand for these materials is driven by the need for fuel efficiency, durability, and safety in modern aircraft. As the aerospace industry continues to grow and evolve, the Global Aerospace Grade Aramid Fiber Honeycomb Market is expected to expand, driven by technological advancements and increasing adoption of lightweight materials in aircraft design.

Hexagonal, Rectangular(Overexpanded), Pentagonal in the Global Aerospace Grade Aramid Fiber Honeycomb Market:

Hexagonal, Rectangular (Overexpanded), and Pentagonal honeycomb structures are key configurations in the Global Aerospace Grade Aramid Fiber Honeycomb Market, each offering unique benefits and applications. Hexagonal honeycomb is the most common and widely used structure due to its excellent balance of strength and weight. The hexagonal cells provide uniform strength distribution, making it ideal for applications requiring high structural integrity and lightweight properties, such as aircraft wings, fuselage panels, and flooring. The hexagonal configuration also allows for efficient material usage, reducing waste and cost. Rectangular (Overexpanded) honeycomb, on the other hand, features elongated cells that provide enhanced flexibility and impact resistance. This structure is particularly useful in areas where the material needs to conform to complex shapes or absorb energy from impacts, such as in aircraft interiors, cargo compartments, and leading edges of wings. The overexpanded design allows for better drapability and easier installation in curved or irregular surfaces. Pentagonal honeycomb structures, while less common, offer unique advantages in specific applications. The pentagonal cells provide a higher degree of isotropy, meaning the material exhibits similar properties in all directions. This makes pentagonal honeycomb suitable for applications where uniform strength and stiffness are required, such as in certain structural components and aerospace insulation panels. Each of these honeycomb configurations plays a crucial role in the aerospace industry, contributing to the overall performance, safety, and efficiency of modern aircraft. The choice of honeycomb structure depends on the specific requirements of the application, including factors such as load-bearing capacity, impact resistance, flexibility, and ease of installation. As the aerospace industry continues to innovate and push the boundaries of material science, the demand for these specialized honeycomb structures is expected to grow, driving further advancements in the Global Aerospace Grade Aramid Fiber Honeycomb Market.

Civil Aircraft, Military Aircraft in the Global Aerospace Grade Aramid Fiber Honeycomb Market:

The usage of Global Aerospace Grade Aramid Fiber Honeycomb Market materials in civil and military aircraft is extensive and varied, driven by the need for lightweight, durable, and high-performance components. In civil aircraft, aramid fiber honeycomb materials are used in a wide range of applications to enhance fuel efficiency, reduce weight, and improve overall performance. These materials are commonly found in aircraft interiors, including seats, overhead bins, and flooring, where their lightweight properties contribute to significant weight savings. Additionally, aramid fiber honeycomb is used in structural components such as fuselage panels, wings, and control surfaces, where their high strength-to-weight ratio ensures structural integrity while minimizing weight. The use of these materials in civil aircraft helps airlines reduce fuel consumption, lower operating costs, and meet stringent environmental regulations. In military aircraft, the demand for aramid fiber honeycomb materials is driven by the need for advanced performance, durability, and survivability. These materials are used in a variety of applications, including armor plating, structural components, and interior fittings. The lightweight and high-strength properties of aramid fiber honeycomb make it ideal for use in aircraft that require high maneuverability, speed, and payload capacity. Additionally, the material's resistance to heat and impact makes it suitable for use in combat and high-stress environments. Military aircraft also benefit from the material's ability to absorb energy and reduce the impact of explosions and ballistic threats, enhancing the safety and survivability of both the aircraft and its occupants. Overall, the usage of Global Aerospace Grade Aramid Fiber Honeycomb Market materials in civil and military aircraft plays a crucial role in advancing the performance, safety, and efficiency of modern aviation. As the aerospace industry continues to evolve, the demand for these advanced materials is expected to grow, driving further innovation and development in the market.

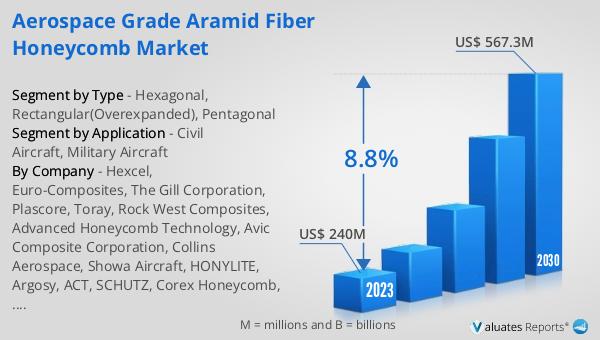

Global Aerospace Grade Aramid Fiber Honeycomb Market Outlook:

The global Aerospace Grade Aramid Fiber Honeycomb market was valued at US$ 240 million in 2023 and is anticipated to reach US$ 567.3 million by 2030, witnessing a CAGR of 8.8% during the forecast period 2024-2030. According to the survey and statistics of the research team, the global aramid paper market sales reached 480 million yuan in 2022 and are expected to reach 890 million yuan in 2029, with a compound annual growth rate (CAGR) of 9.1% from 2023 to 2029. North America is the largest production region, with about 73% share, followed by China and Japan with 20% and 8% shares, respectively. North America is also the largest market, with a share of about 44%, followed by Asia Pacific and Europe with 42% and 14%, respectively.

| Report Metric | Details |

| Report Name | Aerospace Grade Aramid Fiber Honeycomb Market |

| Accounted market size in 2023 | US$ 240 million |

| Forecasted market size in 2030 | US$ 567.3 million |

| CAGR | 8.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexcel, Euro-Composites, The Gill Corporation, Plascore, Toray, Rock West Composites, Advanced Honeycomb Technology, Avic Composite Corporation, Collins Aerospace, Showa Aircraft, HONYLITE, Argosy, ACT, SCHUTZ, Corex Honeycomb, Haxcore, Jiaxing Joybusiness, Regal, Wuxi GDE Technology, TUSUN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |