What is Global Vinyl Resin Market?

The Global Vinyl Resin Market refers to the worldwide industry involved in the production, distribution, and application of vinyl resins. Vinyl resins are a type of synthetic polymer derived from vinyl monomers, which are used in a variety of applications due to their versatility, durability, and chemical resistance. These resins are commonly used in the manufacturing of coatings, adhesives, plastics, and other materials that require strong, long-lasting properties. The market for vinyl resins is driven by demand from various industries, including automotive, construction, electronics, and packaging. As these industries continue to grow and evolve, the need for high-performance materials like vinyl resins increases, leading to advancements in resin technology and production methods. The global market is characterized by a diverse range of products, each tailored to specific applications and performance requirements, making it a dynamic and competitive field.

Standard Bisphenol A Epoxy Vinyl Version, Flame Retardant Epoxy Vinyl Type, Phenolic Phenolic Epoxy Vinyl Model, High Crosslinked Density Phenolic Epoxy Vinyl, Flexible Vinyl Ester Type, PU Modified Epoxy Vinyl, Others in the Global Vinyl Resin Market:

The Global Vinyl Resin Market encompasses a variety of specialized types, each designed to meet specific needs and applications. Standard Bisphenol A Epoxy Vinyl Version is known for its excellent mechanical properties and chemical resistance, making it suitable for coatings and adhesives. Flame Retardant Epoxy Vinyl Type is engineered to provide enhanced fire resistance, crucial for applications in construction and electronics where safety is paramount. Phenolic Phenolic Epoxy Vinyl Model offers superior thermal stability and chemical resistance, ideal for high-temperature environments and harsh chemical conditions. High Crosslinked Density Phenolic Epoxy Vinyl is designed for applications requiring exceptional strength and durability, such as in industrial coatings and structural components. Flexible Vinyl Ester Type provides a balance of flexibility and toughness, making it suitable for applications that require both durability and some degree of flexibility, such as in automotive parts and sporting goods. PU Modified Epoxy Vinyl combines the properties of polyurethane and epoxy, offering enhanced toughness, flexibility, and chemical resistance, making it ideal for coatings, adhesives, and sealants. Other types of vinyl resins include specialized formulations tailored for niche applications, such as those requiring specific electrical properties or enhanced environmental resistance. Each type of vinyl resin is developed to meet the unique demands of its intended application, ensuring optimal performance and longevity. The diversity within the Global Vinyl Resin Market highlights the importance of innovation and customization in meeting the evolving needs of various industries.

The Chemical Industry, Glass Products, Sports Goods in the Global Vinyl Resin Market:

The Global Vinyl Resin Market finds extensive usage across several key industries, including The Chemical Industry, Glass Products, and Sports Goods. In The Chemical Industry, vinyl resins are utilized for their excellent chemical resistance and durability. They are commonly used in the production of coatings, adhesives, and sealants that need to withstand harsh chemical environments. These resins help in protecting surfaces from corrosion and chemical damage, thereby extending the lifespan of industrial equipment and infrastructure. In the Glass Products industry, vinyl resins are used to enhance the strength and durability of glass items. They are often applied as coatings to improve the scratch resistance and impact strength of glass products, making them more resilient and long-lasting. This is particularly important in applications such as automotive windshields, architectural glass, and electronic displays, where durability and safety are critical. In the realm of Sports Goods, vinyl resins are valued for their flexibility, toughness, and lightweight properties. They are used in the manufacturing of various sports equipment, including protective gear, helmets, and sporting goods like tennis rackets and golf clubs. The use of vinyl resins in these products helps to improve performance, safety, and durability, providing athletes with high-quality equipment that can withstand rigorous use. The versatility and performance characteristics of vinyl resins make them an essential material in these industries, driving innovation and enhancing product quality.

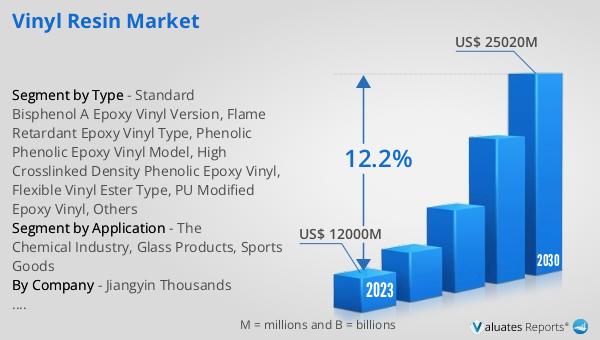

Global Vinyl Resin Market Outlook:

The global Vinyl Resin market was valued at US$ 12,000 million in 2023 and is anticipated to reach US$ 25,020 million by 2030, witnessing a CAGR of 12.2% during the forecast period 2024-2030. In 2021, China's vinyl resin demand was 116,200 tons, a year-on-year increase of 7.1%. In 2022, China's vinyl resin demand was 113,000 tons, a year-on-year increase of 2.7%. With the development of the industry and the advancement of technology, vinyl resin has also developed towards functionalization in recent years, breaking the original technical performance barriers of vinyl resin. Innovations such as higher temperature resistance, stronger oxidation resistance, less VOC volatilization or products with no volatilization, lower shrinkage, stronger toughness, and thickening properties have emerged, adding new vitality to the vinyl resin industry. These advancements have enabled vinyl resins to meet more stringent performance requirements and expand their application scope, further driving market growth and development.

| Report Metric | Details |

| Report Name | Vinyl Resin Market |

| Accounted market size in 2023 | US$ 12000 million |

| Forecasted market size in 2030 | US$ 25020 million |

| CAGR | 12.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Jiangyin Thousands Chemicals Co., Ltd, Bioplastic Biohybrid Resin, Fujimi Corporation, Chroma Color Corporation, Sylvin Technologies, Inc., Micor Company, Hanwha International LLC, Manner Polymers, Westlake Chemical Corp., Amcor Packaging & Chemicals, Fibre Glast Developments Corp., Birch Plastics, Inc., The Dow Chemical Company, ExxonMobil, Carter Chemicals, Fiberglass Supply Corporation, Shintech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |