What is Global Surface Roughness Measuring Machines Market?

The Global Surface Roughness Measuring Machines Market refers to the worldwide industry focused on the production, distribution, and utilization of machines designed to measure the roughness of surfaces. These machines are essential in various industries to ensure the quality and precision of products by assessing the texture and smoothness of surfaces. Surface roughness is a critical parameter in manufacturing processes, affecting the performance, durability, and appearance of products. The market encompasses a range of technologies and devices, including contact and non-contact measuring machines, each suited for different applications and materials. The demand for these machines is driven by the need for high-quality standards in industries such as automotive, aerospace, electronics, and mechanical engineering. As manufacturing processes become more advanced and precise, the importance of accurate surface roughness measurement continues to grow, making this market a vital component of modern industrial quality control.

Contact Surface Roughness Measuring Machines, Non-Contact Surface Roughness Measuring Machines in the Global Surface Roughness Measuring Machines Market:

Contact Surface Roughness Measuring Machines and Non-Contact Surface Roughness Measuring Machines are two primary categories within the Global Surface Roughness Measuring Machines Market. Contact Surface Roughness Measuring Machines operate by physically touching the surface with a stylus or probe to measure its texture. These machines are highly accurate and can provide detailed information about the surface profile, including peaks, valleys, and overall roughness. They are widely used in industries where precision is paramount, such as automotive and aerospace manufacturing. However, the contact method can sometimes be limited by the potential for wear and tear on both the probe and the surface being measured, especially with delicate or soft materials. On the other hand, Non-Contact Surface Roughness Measuring Machines utilize optical or laser-based technologies to assess surface roughness without physical contact. These machines are ideal for measuring surfaces that are sensitive or difficult to reach, as they eliminate the risk of damage. Non-contact methods can quickly scan large areas and provide high-resolution data, making them suitable for applications in electronics, medical devices, and other high-tech industries. Both types of machines have their advantages and limitations, and the choice between them often depends on the specific requirements of the application, such as the material being measured, the desired level of precision, and the production environment. The Global Surface Roughness Measuring Machines Market continues to evolve with advancements in technology, leading to the development of more sophisticated and versatile measuring solutions that cater to a wide range of industrial needs.

Automotive, Mechanical Products, Electronic Products, Others in the Global Surface Roughness Measuring Machines Market:

The usage of Global Surface Roughness Measuring Machines Market spans several key areas, including automotive, mechanical products, electronic products, and others. In the automotive industry, surface roughness measurement is crucial for ensuring the quality and performance of various components such as engine parts, transmission systems, and body panels. Precise surface textures can significantly impact the efficiency, durability, and noise levels of automotive parts, making roughness measurement an integral part of the manufacturing process. In the realm of mechanical products, surface roughness measuring machines are used to assess the finish of gears, bearings, and other critical components. Accurate surface measurements help in reducing friction, wear, and tear, thereby enhancing the lifespan and reliability of mechanical systems. For electronic products, surface roughness measurement is essential in the production of circuit boards, connectors, and semiconductor devices. Smooth and precise surfaces are necessary to ensure proper electrical conductivity and performance, as well as to prevent short circuits and other defects. Additionally, surface roughness measuring machines find applications in other industries such as medical devices, where the texture of surgical instruments and implants can affect their functionality and safety. In the aerospace sector, these machines help in maintaining the high standards required for aircraft components, ensuring their performance and safety. Overall, the Global Surface Roughness Measuring Machines Market plays a vital role in maintaining quality and precision across various industries, contributing to the production of reliable and high-performance products.

Global Surface Roughness Measuring Machines Market Outlook:

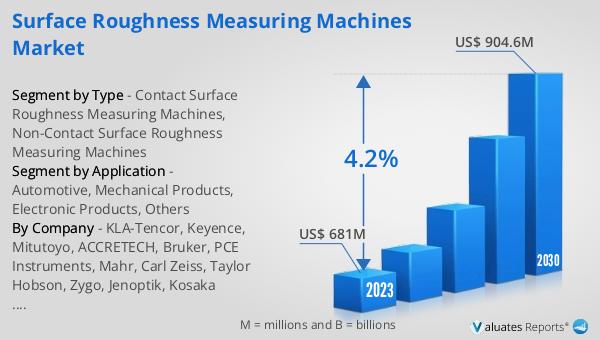

The global Surface Roughness Measuring Machines market was valued at US$ 681 million in 2023 and is anticipated to reach US$ 904.6 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This growth reflects the increasing demand for high-precision measurement tools across various industries. As manufacturing processes become more sophisticated, the need for accurate surface roughness measurement becomes more critical. Industries such as automotive, aerospace, electronics, and medical devices rely heavily on these machines to ensure the quality and performance of their products. The market's expansion is driven by technological advancements that enhance the capabilities and efficiency of surface roughness measuring machines. Innovations in both contact and non-contact measurement technologies are enabling more precise and faster assessments, catering to the evolving needs of modern manufacturing. The growing emphasis on quality control and the adoption of stringent industry standards further contribute to the market's growth. As a result, the Global Surface Roughness Measuring Machines Market is poised to play an increasingly important role in supporting the production of high-quality, reliable, and efficient products across a wide range of applications.

| Report Metric | Details |

| Report Name | Surface Roughness Measuring Machines Market |

| Accounted market size in 2023 | US$ 681 million |

| Forecasted market size in 2030 | US$ 904.6 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KLA-Tencor, Keyence, Mitutoyo, ACCRETECH, Bruker, PCE Instruments, Mahr, Carl Zeiss, Taylor Hobson, Zygo, Jenoptik, Kosaka Laboratory, Polytec, Chotest, Shaanxi Wale M&E Technology, Guangzhou Weierxin Precision Instrument |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |