What is Global Spiral Groove Elastic Coupling Market?

The Global Spiral Groove Elastic Coupling Market is a specialized segment within the broader mechanical coupling industry. These couplings are designed to connect two shafts together, allowing for the transmission of torque while accommodating misalignment and reducing vibration. The spiral groove design provides flexibility and elasticity, which helps in absorbing shocks and compensating for angular, parallel, and axial misalignments. This makes them particularly useful in applications where precision and reliability are critical. The market for these couplings is driven by their widespread use in various industries, including automotive, aerospace, manufacturing, and robotics. As industries continue to automate and seek more efficient machinery, the demand for high-performance couplings like the spiral groove elastic type is expected to grow. These couplings are known for their durability, ease of installation, and maintenance, making them a preferred choice for engineers and technicians. The market is also influenced by advancements in materials and manufacturing technologies, which enhance the performance and lifespan of these couplings. Overall, the Global Spiral Groove Elastic Coupling Market is poised for steady growth, driven by the increasing need for reliable and efficient mechanical components in various industrial applications.

Jaw Type, Gear Type, Pin Type, Other in the Global Spiral Groove Elastic Coupling Market:

The Global Spiral Groove Elastic Coupling Market can be categorized into several types based on their design and application, including Jaw Type, Gear Type, Pin Type, and others. Jaw Type couplings are among the most commonly used due to their simplicity and effectiveness. They consist of two metal hubs with interlocking jaws and an elastomeric element, known as a spider, which sits between them. This design allows for the absorption of shocks and vibrations, making them ideal for applications where smooth torque transmission is essential. They are widely used in pumps, compressors, and other machinery where alignment is a concern. Gear Type couplings, on the other hand, are designed for high-torque applications. They consist of two hubs with external teeth that mesh with internal teeth on a sleeve. This design provides high torque capacity and can accommodate significant misalignment. Gear Type couplings are commonly used in heavy machinery, such as cranes and conveyors, where robust performance is required. Pin Type couplings use pins and bushings to connect the two hubs. The pins are usually made of metal, while the bushings are made of elastomeric material. This design allows for flexibility and shock absorption, making them suitable for applications where there is a need to dampen vibrations and accommodate misalignment. They are often used in automotive and industrial machinery. Other types of spiral groove elastic couplings include disc couplings, which use a series of thin, flexible metal discs to transmit torque while accommodating misalignment. These are typically used in high-precision applications, such as robotics and aerospace, where accuracy and reliability are paramount. Each type of coupling has its own set of advantages and is chosen based on the specific requirements of the application. The diversity in design and functionality ensures that there is a suitable coupling for almost any mechanical system, making the Global Spiral Groove Elastic Coupling Market a versatile and essential component of modern industry.

Agricultural Vehicle, Construction Machinery, Industrial Equipment, Ship, Mining Equipment in the Global Spiral Groove Elastic Coupling Market:

The usage of Global Spiral Groove Elastic Coupling Market spans across various sectors, including Agricultural Vehicles, Construction Machinery, Industrial Equipment, Ships, and Mining Equipment. In agricultural vehicles, these couplings are essential for connecting different parts of the machinery, such as the engine to the transmission or the PTO (Power Take-Off) shaft to various implements. The flexibility and shock-absorbing properties of spiral groove elastic couplings help in reducing wear and tear on the machinery, thereby extending its lifespan and improving reliability. In construction machinery, these couplings are used in equipment like excavators, bulldozers, and cranes. The ability to accommodate misalignment and absorb shocks is crucial in these applications, as construction sites often involve rough and uneven terrain. The couplings ensure smooth operation and reduce the risk of mechanical failure, which is vital for maintaining productivity and safety on the job site. Industrial equipment, such as pumps, compressors, and conveyor systems, also rely heavily on spiral groove elastic couplings. These couplings help in maintaining alignment and reducing vibrations, which can lead to increased efficiency and reduced maintenance costs. In the shipping industry, these couplings are used in various applications, including propulsion systems and auxiliary machinery. The harsh marine environment requires components that can withstand high levels of stress and corrosion, and spiral groove elastic couplings are well-suited for this purpose. They help in ensuring smooth and reliable operation, which is critical for the safety and efficiency of maritime operations. Lastly, in mining equipment, these couplings are used in machinery such as drills, crushers, and conveyors. The demanding conditions of mining operations, including heavy loads and harsh environments, require robust and reliable components. Spiral groove elastic couplings provide the necessary flexibility and durability to handle these challenges, ensuring continuous operation and reducing downtime. Overall, the versatility and reliability of spiral groove elastic couplings make them an indispensable component in a wide range of industries, contributing to improved performance and reduced maintenance costs.

Global Spiral Groove Elastic Coupling Market Outlook:

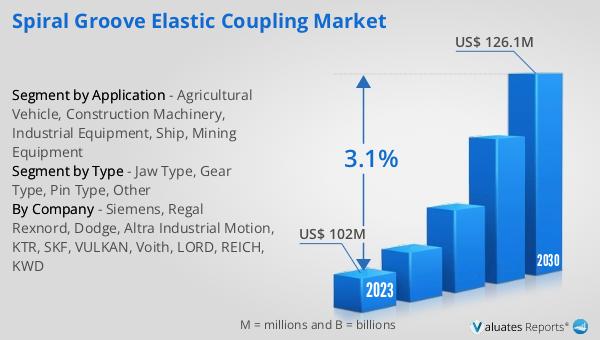

The global Spiral Groove Elastic Coupling market was valued at US$ 102 million in 2023 and is anticipated to reach US$ 126.1 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for reliable and efficient mechanical components across various industries. The projected growth reflects the expanding applications of spiral groove elastic couplings in sectors such as automotive, aerospace, manufacturing, and robotics. As industries continue to seek ways to enhance the performance and longevity of their machinery, the demand for high-quality couplings is expected to rise. The market's growth is also supported by advancements in materials and manufacturing technologies, which contribute to the improved performance and durability of these couplings. The steady CAGR of 3.1% underscores the market's resilience and the ongoing need for innovative solutions in mechanical coupling technology. This positive outlook suggests that the Global Spiral Groove Elastic Coupling Market will continue to play a crucial role in various industrial applications, providing essential components that contribute to the efficiency and reliability of machinery and equipment.

| Report Metric | Details |

| Report Name | Spiral Groove Elastic Coupling Market |

| Accounted market size in 2023 | US$ 102 million |

| Forecasted market size in 2030 | US$ 126.1 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens, Regal Rexnord, Dodge, Altra Industrial Motion, KTR, SKF, VULKAN, Voith, LORD, REICH, KWD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |