What is Global Elastic Couplings for Power Transmission Market?

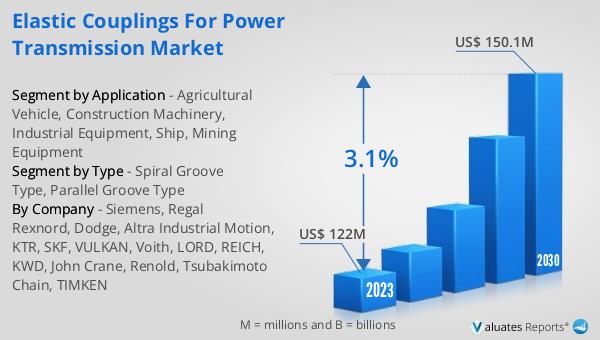

Global Elastic Couplings for Power Transmission Market refers to the industry focused on the production and distribution of elastic couplings used in power transmission systems. These couplings are essential components that connect two shafts together, allowing for the transfer of torque while accommodating misalignment and reducing vibration. The elastic element within these couplings provides flexibility, which helps in compensating for minor misalignments and absorbing shocks, thereby protecting the machinery and enhancing its lifespan. The market for these couplings is driven by their widespread application across various industries, including agriculture, construction, industrial equipment, marine, and mining. As industries continue to seek efficient and reliable power transmission solutions, the demand for elastic couplings is expected to grow. The global market for these couplings was valued at US$ 122 million in 2023 and is projected to reach US$ 150.1 million by 2030, with a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030.

Spiral Groove Type, Parallel Groove Type in the Global Elastic Couplings for Power Transmission Market:

Elastic couplings come in various types, with Spiral Groove Type and Parallel Groove Type being two prominent categories. The Spiral Groove Type elastic coupling features a helical groove pattern that allows for greater flexibility and torsional stiffness. This design is particularly effective in applications where high torque transmission and minimal backlash are required. The spiral grooves enable the coupling to accommodate angular, radial, and axial misalignments, making it suitable for high-precision machinery and equipment. On the other hand, the Parallel Groove Type elastic coupling has parallel grooves that provide a balanced distribution of stress and strain across the coupling. This design is ideal for applications where moderate flexibility and misalignment compensation are needed. The parallel grooves help in reducing vibration and noise, ensuring smooth and efficient power transmission. Both types of elastic couplings are widely used in various industries due to their ability to enhance the performance and reliability of power transmission systems. The choice between Spiral Groove Type and Parallel Groove Type depends on the specific requirements of the application, such as the level of misalignment, torque transmission, and environmental conditions. As industries continue to evolve and demand more efficient power transmission solutions, the market for these elastic couplings is expected to grow, driven by their versatility and effectiveness in various applications.

Agricultural Vehicle, Construction Machinery, Industrial Equipment, Ship, Mining Equipment in the Global Elastic Couplings for Power Transmission Market:

The usage of Global Elastic Couplings for Power Transmission Market spans across several key areas, including Agricultural Vehicles, Construction Machinery, Industrial Equipment, Ships, and Mining Equipment. In agricultural vehicles, elastic couplings are used to connect the engine to various implements, such as plows, harvesters, and tractors. These couplings help in absorbing shocks and vibrations, ensuring smooth operation and reducing wear and tear on the machinery. In construction machinery, elastic couplings are essential for connecting different components, such as engines, gearboxes, and hydraulic systems. They help in accommodating misalignments and reducing vibrations, which enhances the durability and performance of the machinery. In industrial equipment, elastic couplings are used in a wide range of applications, including conveyor systems, pumps, compressors, and generators. They provide flexibility and reliability, ensuring efficient power transmission and reducing maintenance costs. In ships, elastic couplings are used to connect the engine to the propeller shaft, allowing for smooth and efficient power transmission while accommodating misalignments caused by the movement of the ship. In mining equipment, elastic couplings are used to connect various components, such as crushers, conveyors, and drilling machines. They help in absorbing shocks and vibrations, ensuring smooth operation and reducing downtime. Overall, the usage of elastic couplings in these areas helps in enhancing the performance, reliability, and lifespan of the machinery, making them an essential component in power transmission systems.

Global Elastic Couplings for Power Transmission Market Outlook:

The global market for Elastic Couplings for Power Transmission is driven by the unique benefits provided by the elastic element within the coupling. This elastic element plays a crucial role in compensating for misalignments and absorbing shocks, which helps in protecting the connected machinery and enhancing its performance. In 2023, the market was valued at US$ 122 million and is expected to reach US$ 150.1 million by 2030, with a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. The increasing demand for efficient and reliable power transmission solutions across various industries is a key factor driving the growth of this market. As industries continue to evolve and seek advanced solutions for power transmission, the demand for elastic couplings is expected to rise, further boosting the market growth. The versatility and effectiveness of elastic couplings in accommodating misalignments, reducing vibrations, and enhancing the performance of machinery make them a preferred choice in various applications, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Elastic Couplings for Power Transmission Market |

| Accounted market size in 2023 | US$ 122 million |

| Forecasted market size in 2030 | US$ 150.1 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens, Regal Rexnord, Dodge, Altra Industrial Motion, KTR, SKF, VULKAN, Voith, LORD, REICH, KWD, John Crane, Renold, Tsubakimoto Chain, TIMKEN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |