What is Global Safety Interlocking System Market?

The Global Safety Interlocking System Market refers to the industry focused on the development, production, and distribution of safety interlocking systems. These systems are crucial for ensuring the safety and operational efficiency of various industrial processes. Safety interlocking systems are designed to prevent accidents and equipment damage by ensuring that certain conditions are met before machinery or processes can be initiated. They are widely used in industries such as manufacturing, chemical processing, power generation, and food processing, among others. The market for these systems is driven by the increasing emphasis on workplace safety, stringent regulatory requirements, and the need for reliable and efficient safety solutions. As industries continue to prioritize safety and compliance, the demand for advanced safety interlocking systems is expected to grow, leading to innovations and advancements in this field.

Relay Type, Solid State Circuit Type, Programmable Electronic Type in the Global Safety Interlocking System Market:

In the Global Safety Interlocking System Market, there are several types of interlocking systems, including Relay Type, Solid State Circuit Type, and Programmable Electronic Type. Relay Type interlocking systems are among the oldest and most traditional forms of safety interlocking. They use electromechanical relays to control the operation of machinery and processes. These systems are known for their reliability and simplicity, making them suitable for applications where basic safety requirements need to be met. However, they can be bulky and may require regular maintenance due to the mechanical nature of relays. Solid State Circuit Type interlocking systems, on the other hand, utilize solid-state components such as transistors and diodes to achieve interlocking functions. These systems are more compact and have fewer moving parts compared to relay-based systems, resulting in higher reliability and lower maintenance requirements. Solid-state interlocking systems are also faster in operation, making them suitable for applications that require quick response times. Programmable Electronic Type interlocking systems represent the most advanced form of safety interlocking. These systems use programmable logic controllers (PLCs) or other programmable devices to implement complex interlocking logic. They offer high flexibility and can be easily reprogrammed to accommodate changes in the process or machinery. Programmable electronic interlocking systems are ideal for applications that require sophisticated safety functions and integration with other control systems. They also support advanced diagnostics and monitoring capabilities, enhancing overall system performance and safety. Each type of interlocking system has its own advantages and limitations, and the choice of system depends on the specific requirements of the application, including factors such as complexity, reliability, maintenance, and cost. As technology continues to evolve, the Global Safety Interlocking System Market is likely to see further innovations and improvements in these interlocking systems, providing industries with more efficient and effective safety solutions.

Gas Station, Chemical Plant, Power Plant, Food Processing Plant in the Global Safety Interlocking System Market:

The usage of Global Safety Interlocking System Market in various industries such as Gas Stations, Chemical Plants, Power Plants, and Food Processing Plants is crucial for ensuring safety and operational efficiency. In Gas Stations, safety interlocking systems are used to prevent accidents related to fuel dispensing and storage. These systems ensure that fuel pumps operate only under safe conditions, such as when the nozzle is properly inserted into the vehicle's fuel tank. They also prevent the simultaneous operation of incompatible processes, reducing the risk of fires and explosions. In Chemical Plants, safety interlocking systems play a vital role in preventing hazardous chemical reactions and ensuring the safe handling of dangerous substances. These systems control the operation of valves, pumps, and other equipment to ensure that chemicals are mixed and processed under safe conditions. They also help in isolating sections of the plant during maintenance or emergencies, minimizing the risk of accidents. In Power Plants, safety interlocking systems are essential for protecting both personnel and equipment. These systems ensure that critical operations, such as the startup and shutdown of turbines and generators, are carried out safely. They also prevent the simultaneous operation of incompatible systems, reducing the risk of equipment damage and power outages. In Food Processing Plants, safety interlocking systems help in maintaining hygiene and preventing contamination. These systems control the operation of machinery and processes to ensure that food products are processed under safe and sanitary conditions. They also help in preventing cross-contamination by ensuring that different stages of the production process are properly isolated. Overall, the use of safety interlocking systems in these industries helps in enhancing safety, reducing the risk of accidents, and ensuring compliance with regulatory requirements. As industries continue to prioritize safety and efficiency, the demand for advanced safety interlocking systems is expected to grow, driving further innovations and advancements in this field.

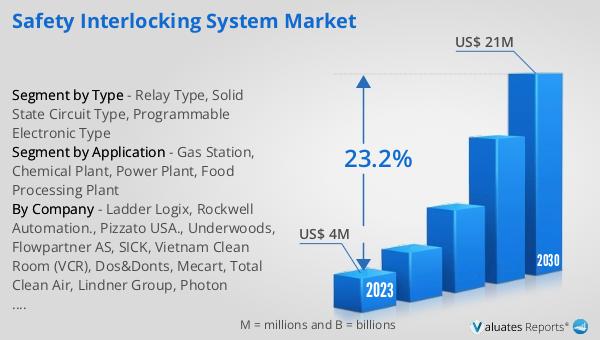

Global Safety Interlocking System Market Outlook:

The global Safety Interlocking System market was valued at US$ 4 million in 2023 and is anticipated to reach US$ 21 million by 2030, witnessing a CAGR of 23.2% during the forecast period 2024-2030. This significant growth reflects the increasing emphasis on safety and regulatory compliance across various industries. The rising awareness about workplace safety and the need to prevent accidents and equipment damage are driving the demand for advanced safety interlocking systems. These systems are becoming an integral part of industrial operations, ensuring that processes are carried out under safe conditions and reducing the risk of hazardous incidents. The market's growth is also supported by technological advancements, which are leading to the development of more efficient and reliable interlocking systems. As industries continue to adopt these advanced safety solutions, the Global Safety Interlocking System Market is expected to witness substantial growth, providing opportunities for innovation and development in this field.

| Report Metric | Details |

| Report Name | Safety Interlocking System Market |

| Accounted market size in 2023 | US$ 4 million |

| Forecasted market size in 2030 | US$ 21 million |

| CAGR | 23.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ladder Logix, Rockwell Automation., Pizzato USA., Underwoods, Flowpartner AS, SICK, Vietnam Clean Room (VCR), Dos&Donts, Mecart, Total Clean Air, Lindner Group, Photon Cleantech, Easypharma, YOUR DEVICE GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |