What is Global Heat Exchange Tube Market?

The Global Heat Exchange Tube Market is a significant segment within the broader heat exchanger industry. Heat exchange tubes are critical components used in various types of heat exchangers, which are devices designed to transfer heat between two or more fluids. These tubes are typically made from materials like stainless steel, copper, and other alloys that can withstand high temperatures and pressures. The market for these tubes is driven by their extensive use in industries such as power generation, chemical processing, oil and gas, HVAC (heating, ventilation, and air conditioning), and food and beverage processing. The demand for heat exchange tubes is influenced by factors such as industrial growth, technological advancements, and the need for energy-efficient systems. As industries continue to expand and seek more efficient ways to manage heat transfer, the global heat exchange tube market is expected to grow steadily. The market's growth is also supported by the increasing focus on sustainability and energy conservation, which drives the adoption of advanced heat exchange technologies.

Separate, Integral in the Global Heat Exchange Tube Market:

In the Global Heat Exchange Tube Market, there are two primary types of tubes: separate and integral. Separate heat exchange tubes are individual tubes that are inserted into the heat exchanger shell. These tubes can be easily replaced or maintained without affecting the entire system. They are commonly used in applications where maintenance and replacement are frequent, such as in power plants and chemical processing units. The advantage of separate tubes is their flexibility and ease of maintenance, which can lead to reduced downtime and operational costs. On the other hand, integral heat exchange tubes are built into the heat exchanger unit itself. These tubes are not meant to be replaced individually; instead, the entire unit is serviced or replaced as needed. Integral tubes are often used in applications where the heat exchanger is subjected to harsh conditions and requires a robust design, such as in oil and gas processing and heavy industrial applications. The choice between separate and integral tubes depends on factors like the specific application, maintenance requirements, and cost considerations. Both types of tubes play a crucial role in ensuring efficient heat transfer and maintaining the overall performance of heat exchangers in various industries.

Metallurgical Industry, Chemical Industry, Ceramic Industry, Machining Industry, Others in the Global Heat Exchange Tube Market:

The Global Heat Exchange Tube Market finds extensive usage across several industries, including the metallurgical, chemical, ceramic, and machining industries, among others. In the metallurgical industry, heat exchange tubes are used in furnaces, heat treatment equipment, and other processes that require precise temperature control. These tubes help in maintaining the desired temperature levels, ensuring the quality and consistency of the metallurgical processes. In the chemical industry, heat exchange tubes are essential for processes such as distillation, condensation, and chemical reactions. They facilitate the transfer of heat between different chemical substances, enabling efficient and safe chemical processing. The ceramic industry also relies on heat exchange tubes for processes like kiln heating and material synthesis. These tubes help in achieving the high temperatures required for ceramic production while ensuring energy efficiency. In the machining industry, heat exchange tubes are used in cooling systems for machine tools and equipment. They help in dissipating the heat generated during machining operations, preventing overheating and ensuring the longevity of the equipment. Other industries that utilize heat exchange tubes include the food and beverage industry, where they are used in pasteurization and refrigeration processes, and the HVAC industry, where they are used in heating and cooling systems. The versatility and efficiency of heat exchange tubes make them indispensable in a wide range of industrial applications.

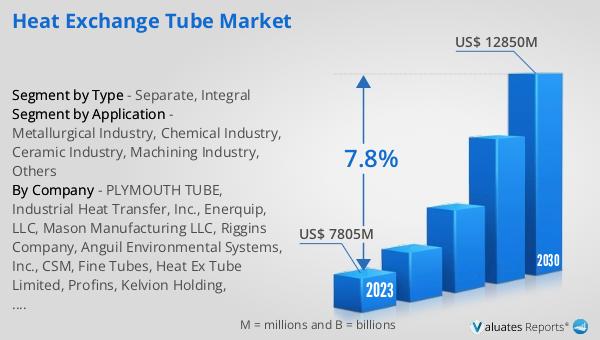

Global Heat Exchange Tube Market Outlook:

The global Heat Exchange Tube market was valued at US$ 7805 million in 2023 and is anticipated to reach US$ 12850 million by 2030, witnessing a CAGR of 7.8% during the forecast period 2024-2030. This significant growth reflects the increasing demand for efficient heat transfer solutions across various industries. The market's expansion is driven by factors such as industrial growth, technological advancements, and the need for energy-efficient systems. As industries continue to seek ways to optimize their processes and reduce energy consumption, the demand for high-quality heat exchange tubes is expected to rise. The market's growth is also supported by the increasing focus on sustainability and energy conservation, which drives the adoption of advanced heat exchange technologies. The projected growth rate of 7.8% CAGR indicates a robust market outlook, with significant opportunities for manufacturers and suppliers of heat exchange tubes. This growth trajectory underscores the importance of heat exchange tubes in modern industrial applications and highlights the ongoing need for efficient and reliable heat transfer solutions.

| Report Metric | Details |

| Report Name | Heat Exchange Tube Market |

| Accounted market size in 2023 | US$ 7805 million |

| Forecasted market size in 2030 | US$ 12850 million |

| CAGR | 7.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PLYMOUTH TUBE, Industrial Heat Transfer, Inc., Enerquip, LLC, Mason Manufacturing LLC, Riggins Company, Anguil Environmental Systems, Inc., CSM, Fine Tubes, Heat Ex Tube Limited, Profins, Kelvion Holding, Ecootherm Limited, Tridan International, Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |