What is Global Flue Gas Desulfurization Tower Market?

The Global Flue Gas Desulfurization (FGD) Tower Market is a specialized sector focused on the development and deployment of towers designed to remove sulfur dioxide (SO2) from flue gases produced by industrial processes. These towers are essential in reducing air pollution and meeting environmental regulations. The market encompasses various types of FGD towers, each utilizing different technologies to achieve desulfurization. The demand for these towers is driven by stringent environmental regulations, increasing industrial activities, and the need for cleaner energy production. The market is characterized by continuous innovation and technological advancements aimed at improving efficiency and reducing operational costs. Companies operating in this market are investing in research and development to enhance the performance of FGD towers and expand their application across various industries. The global FGD tower market is poised for significant growth, driven by the increasing awareness of environmental issues and the need for sustainable industrial practices.

Spray Tower, Bubbling Tower, Liquid Column Tower, Packed Tower in the Global Flue Gas Desulfurization Tower Market:

Spray Tower, Bubbling Tower, Liquid Column Tower, and Packed Tower are four primary types of towers used in the Global Flue Gas Desulfurization (FGD) Tower Market. Each type has unique characteristics and applications. Spray Towers are widely used due to their simplicity and effectiveness. They operate by spraying a liquid absorbent into the flue gas stream, which reacts with the sulfur dioxide to form a byproduct that can be removed. These towers are particularly effective in handling large volumes of gas and are commonly used in power plants and industrial facilities. Bubbling Towers, also known as bubble column reactors, utilize a liquid absorbent that is bubbled through the flue gas. The gas bubbles rise through the liquid, allowing for efficient contact and reaction with the absorbent. This type of tower is known for its high mass transfer efficiency and is often used in chemical processing industries. Liquid Column Towers operate by passing the flue gas through a column of liquid absorbent. The gas is forced to bubble through the liquid, allowing for effective contact and reaction. These towers are highly efficient and are used in applications where high levels of desulfurization are required. Packed Towers are filled with packing material that provides a large surface area for the gas and liquid to contact. The flue gas passes through the packing material, allowing for efficient absorption of sulfur dioxide. Packed Towers are known for their high efficiency and low pressure drop, making them suitable for a wide range of industrial applications. Each type of FGD tower has its advantages and is selected based on the specific requirements of the application, including the volume of gas to be treated, the concentration of sulfur dioxide, and the desired level of desulfurization. The choice of tower type also depends on factors such as cost, maintenance requirements, and operational efficiency. As the demand for cleaner industrial processes continues to grow, the development and deployment of advanced FGD towers will play a crucial role in reducing air pollution and meeting environmental regulations.

Chemical Industry, Metalworking Industry, Thermal Power Industry, Food Industry, Fertilizer Industry in the Global Flue Gas Desulfurization Tower Market:

The Global Flue Gas Desulfurization (FGD) Tower Market finds extensive usage across various industries, including the Chemical Industry, Metalworking Industry, Thermal Power Industry, Food Industry, and Fertilizer Industry. In the Chemical Industry, FGD towers are used to remove sulfur dioxide from the flue gases produced during chemical manufacturing processes. This is essential to prevent the release of harmful pollutants into the atmosphere and to comply with environmental regulations. The Metalworking Industry also relies on FGD towers to control emissions from processes such as smelting and refining. These towers help in reducing the environmental impact of metal production and ensure compliance with air quality standards. In the Thermal Power Industry, FGD towers are critical for controlling emissions from coal-fired power plants. These plants are significant sources of sulfur dioxide emissions, and the use of FGD towers helps in reducing these emissions to meet regulatory requirements. The Food Industry uses FGD towers to control emissions from processes such as food processing and packaging. This is important to ensure that the industry operates in an environmentally responsible manner and to prevent the release of harmful pollutants. The Fertilizer Industry also benefits from the use of FGD towers to control emissions from the production of fertilizers. This helps in reducing the environmental impact of fertilizer production and ensures compliance with environmental regulations. Overall, the use of FGD towers in these industries is essential for reducing air pollution, meeting environmental regulations, and promoting sustainable industrial practices.

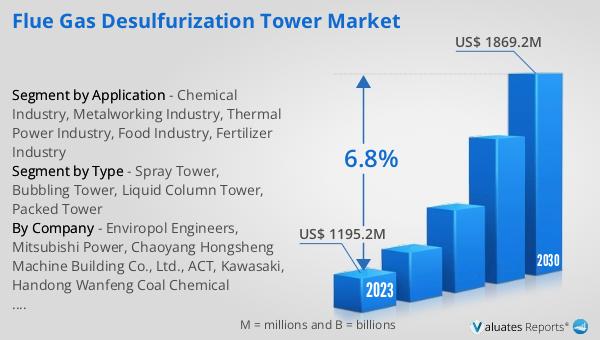

Global Flue Gas Desulfurization Tower Market Outlook:

The global Flue Gas Desulfurization (FGD) Tower market was valued at US$ 1195.2 million in 2023 and is anticipated to reach US$ 1869.2 million by 2030, witnessing a CAGR of 6.8% during the forecast period 2024-2030. This market growth is driven by the increasing demand for cleaner industrial processes and the need to comply with stringent environmental regulations. The market is characterized by continuous innovation and technological advancements aimed at improving the efficiency and effectiveness of FGD towers. Companies operating in this market are investing in research and development to enhance the performance of their products and expand their application across various industries. The growing awareness of environmental issues and the need for sustainable industrial practices are also contributing to the market's growth. As industries continue to seek ways to reduce their environmental impact, the demand for advanced FGD towers is expected to increase, driving the market's expansion over the forecast period.

| Report Metric | Details |

| Report Name | Flue Gas Desulfurization Tower Market |

| Accounted market size in 2023 | US$ 1195.2 million |

| Forecasted market size in 2030 | US$ 1869.2 million |

| CAGR | 6.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Enviropol Engineers, Mitsubishi Power, Chaoyang Hongsheng Machine Building Co., Ltd., ACT, Kawasaki, Handong Wanfeng Coal Chemical Equipment Manufacturing Co, Weihai Puyi Marine Environmental Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |