What is Global Fire-resistant and Heat-resistant Fabric Market?

The global fire-resistant and heat-resistant fabric market is a specialized segment within the broader textile industry, focusing on materials that can withstand high temperatures and resist ignition. These fabrics are essential for safety in various high-risk environments, such as industrial settings, firefighting, and military applications. The market encompasses a range of materials, including aramid fibers, melamine fibers, and other specialized fabrics designed to offer protection against extreme heat and flames. The demand for these fabrics is driven by stringent safety regulations and the need for protective clothing in hazardous work environments. As industries continue to prioritize worker safety and regulatory compliance, the market for fire-resistant and heat-resistant fabrics is expected to grow. These fabrics are not only used in protective clothing but also in other applications such as upholstery, curtains, and automotive interiors, where fire resistance is crucial. The market is characterized by continuous innovation, with manufacturers developing new materials and technologies to enhance the performance and durability of these fabrics. Overall, the global fire-resistant and heat-resistant fabric market plays a vital role in ensuring safety and protection in various high-risk environments.

Aramid Fiber, Melamine Fiber, Others in the Global Fire-resistant and Heat-resistant Fabric Market:

Aramid fibers, melamine fibers, and other specialized materials are the backbone of the global fire-resistant and heat-resistant fabric market. Aramid fibers, such as Kevlar and Nomex, are renowned for their exceptional strength and heat resistance. These fibers are synthetic polymers that can withstand temperatures up to 500 degrees Celsius without degrading. They are commonly used in protective clothing for firefighters, military personnel, and industrial workers. Aramid fibers are also used in composite materials for aerospace and automotive applications due to their high strength-to-weight ratio. Melamine fibers, on the other hand, are known for their excellent flame resistance and thermal stability. These fibers are made from melamine-formaldehyde resin and can withstand temperatures up to 400 degrees Celsius. Melamine fibers are often used in protective clothing, insulation materials, and fire-blocking layers in mattresses and upholstery. Other specialized materials in the market include PBI (polybenzimidazole) fibers, which offer superior flame resistance and thermal stability, and carbon fibers, which are known for their high strength and heat resistance. These materials are used in a variety of applications, including protective clothing, aerospace, and automotive industries. The global fire-resistant and heat-resistant fabric market is characterized by continuous innovation, with manufacturers developing new materials and technologies to enhance the performance and durability of these fabrics. For example, some manufacturers are developing fabrics that combine the properties of different fibers to create multi-functional materials that offer both flame resistance and thermal insulation. Others are focusing on developing eco-friendly and sustainable materials that meet the growing demand for environmentally responsible products. Overall, the market for fire-resistant and heat-resistant fabrics is driven by the need for safety and protection in high-risk environments, and the continuous development of new materials and technologies is expected to drive growth in the market.

Oil and Gas, Utilities, Electrician, Combustible Dust, Welding, Molten Metal, Others in the Global Fire-resistant and Heat-resistant Fabric Market:

The global fire-resistant and heat-resistant fabric market finds extensive usage in various high-risk industries, including oil and gas, utilities, electrical work, combustible dust environments, welding, molten metal handling, and others. In the oil and gas industry, these fabrics are essential for protecting workers from the extreme heat and potential fire hazards associated with drilling and refining operations. Workers in this industry often wear flame-resistant clothing made from aramid or melamine fibers to ensure their safety. In the utilities sector, fire-resistant fabrics are used to protect workers who maintain and repair electrical grids and other infrastructure. Electricians, in particular, require protective clothing that can withstand electrical arcs and high temperatures. Fire-resistant fabrics are also crucial in environments where combustible dust is present, such as grain elevators, food processing plants, and chemical manufacturing facilities. These fabrics help prevent ignition and protect workers from potential explosions. In welding operations, fire-resistant fabrics are used to protect workers from sparks, molten metal splashes, and intense heat. Welders often wear protective clothing made from aramid fibers or other heat-resistant materials to ensure their safety. Similarly, in industries that handle molten metal, such as foundries and metalworking plants, fire-resistant fabrics are essential for protecting workers from the extreme heat and potential splashes of molten metal. Other industries that benefit from fire-resistant and heat-resistant fabrics include firefighting, military, and aerospace. Firefighters rely on protective clothing made from aramid fibers to shield them from flames and high temperatures. Military personnel use fire-resistant fabrics in their uniforms and gear to protect them in combat situations. In the aerospace industry, fire-resistant fabrics are used in aircraft interiors and protective clothing for pilots and crew members. Overall, the global fire-resistant and heat-resistant fabric market plays a crucial role in ensuring the safety and protection of workers in various high-risk industries.

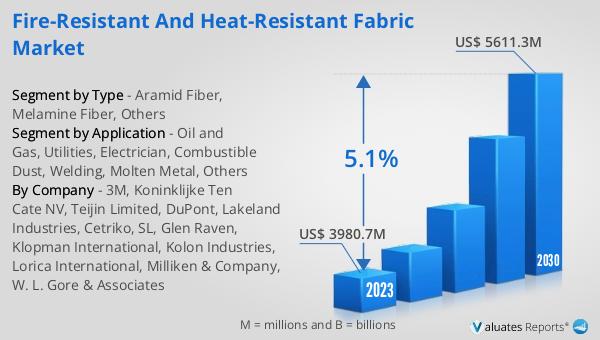

Global Fire-resistant and Heat-resistant Fabric Market Outlook:

The global fire-resistant and heat-resistant fabric market was valued at approximately USD 3980.7 million in 2023. It is projected to reach around USD 5611.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This growth is driven by increasing safety regulations and the need for protective clothing in various high-risk industries. The market's expansion is also fueled by continuous innovation in materials and technologies, which enhance the performance and durability of fire-resistant and heat-resistant fabrics. As industries prioritize worker safety and regulatory compliance, the demand for these specialized fabrics is expected to rise. The market's growth is further supported by the development of eco-friendly and sustainable materials, meeting the growing demand for environmentally responsible products. Overall, the global fire-resistant and heat-resistant fabric market is poised for significant growth in the coming years, driven by the need for safety and protection in high-risk environments.

| Report Metric | Details |

| Report Name | Fire-resistant and Heat-resistant Fabric Market |

| Accounted market size in 2023 | US$ 3980.7 million |

| Forecasted market size in 2030 | US$ 5611.3 million |

| CAGR | 5.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Koninklijke Ten Cate NV, Teijin Limited, DuPont, Lakeland Industries, Cetriko, SL, Glen Raven, Klopman International, Kolon Industries, Lorica International, Milliken & Company, W. L. Gore & Associates |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |