What is Global Copper Foil for Printed Circuit Board Market?

The global Copper Foil for Printed Circuit Board (PCB) market is a specialized segment within the broader electronics materials industry. Copper foil is a critical component in the manufacturing of PCBs, which are essential for the functioning of electronic devices. The market encompasses various types of copper foils, including rolled and electrolytic, each serving different applications based on their properties. The demand for copper foil is driven by the increasing production of electronic devices, advancements in technology, and the growing need for miniaturization in electronics. The market is characterized by a mix of direct and indirect sales channels, catering to diverse industries such as automotive, military, aerospace, and consumer electronics. The global market for copper foil in PCBs is expected to grow steadily, driven by the continuous innovation and expansion of the electronics industry.

Rolled Copper Foil, Electrolytic Copper Foil in the Global Copper Foil for Printed Circuit Board Market:

Rolled copper foil and electrolytic copper foil are the two primary types of copper foils used in the global Copper Foil for Printed Circuit Board market. Rolled copper foil is produced through a mechanical process that involves rolling copper ingots into thin sheets. This type of foil is known for its high ductility, excellent surface finish, and superior mechanical properties, making it ideal for applications that require flexibility and durability. Rolled copper foil is commonly used in high-frequency circuits, flexible PCBs, and other applications where mechanical strength and flexibility are crucial. On the other hand, electrolytic copper foil is manufactured through an electrochemical process that involves depositing copper onto a rotating drum from a copper sulfate solution. This type of foil is characterized by its high purity, uniform thickness, and excellent electrical conductivity. Electrolytic copper foil is widely used in rigid PCBs, multilayer PCBs, and other applications where high electrical performance is required. Both types of copper foils play a vital role in the PCB manufacturing process, contributing to the overall performance and reliability of electronic devices. The choice between rolled and electrolytic copper foil depends on the specific requirements of the application, including factors such as mechanical properties, electrical performance, and cost considerations. The global market for copper foil in PCBs is highly competitive, with numerous manufacturers offering a wide range of products to meet the diverse needs of the electronics industry. As technology continues to evolve, the demand for high-quality copper foil is expected to increase, driving further innovation and development in the market.

Direct Sales, Indirect Sales, Automobile Industry, Military and Aerospace, Other in the Global Copper Foil for Printed Circuit Board Market:

The usage of global copper foil for printed circuit boards spans various areas, including direct sales, indirect sales, the automobile industry, military and aerospace, and other sectors. In direct sales, manufacturers of copper foil sell their products directly to PCB manufacturers, ensuring a streamlined supply chain and better control over product quality and specifications. This direct relationship allows for customized solutions and quicker response times to market demands. Indirect sales involve distributors and resellers who purchase copper foil from manufacturers and sell it to smaller PCB producers or other end-users. This channel helps manufacturers reach a broader market and provides end-users with easier access to copper foil products. In the automobile industry, copper foil is used in the production of PCBs for various automotive applications, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The increasing complexity and electronic content in modern vehicles drive the demand for high-quality copper foil. In the military and aerospace sectors, copper foil is used in PCBs for critical applications such as communication systems, radar, navigation, and control systems. The stringent performance and reliability requirements in these sectors necessitate the use of high-grade copper foil. Other sectors that utilize copper foil for PCBs include consumer electronics, telecommunications, and industrial equipment. The versatility and essential role of copper foil in the manufacturing of PCBs make it a critical component in the electronics industry, driving its demand across various sectors.

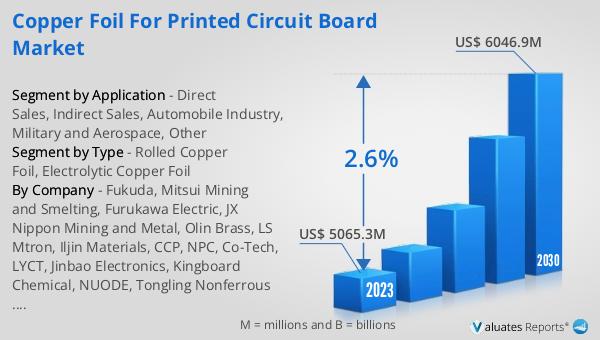

Global Copper Foil for Printed Circuit Board Market Outlook:

The global Copper Foil for Printed Circuit Board market was valued at US$ 5065.3 million in 2023 and is projected to reach US$ 6046.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. This steady growth is indicative of the increasing demand for copper foil in the electronics industry, driven by advancements in technology and the proliferation of electronic devices. The market's expansion is supported by the continuous innovation in PCB manufacturing processes and the growing need for high-performance materials. The projected growth underscores the importance of copper foil as a critical component in the production of PCBs, which are essential for the functioning of a wide range of electronic devices.

| Report Metric | Details |

| Report Name | Copper Foil for Printed Circuit Board Market |

| Accounted market size in 2023 | US$ 5065.3 million |

| Forecasted market size in 2030 | US$ 6046.9 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fukuda, Mitsui Mining and Smelting, Furukawa Electric, JX Nippon Mining and Metal, Olin Brass, LS Mtron, Iljin Materials, CCP, NPC, Co-Tech, LYCT, Jinbao Electronics, Kingboard Chemical, NUODE, Tongling Nonferrous Metal Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |