What is Global Automotive Structural Sheet Metal Market?

The Global Automotive Structural Sheet Metal Market refers to the worldwide industry involved in the production and distribution of sheet metal used in the structural components of vehicles. This market encompasses various types of sheet metals, including galvanized, high-strength, aluminum alloy, stainless steel, and titanium alloy sheet metals. These materials are essential for manufacturing the body and frame of vehicles, providing the necessary strength, durability, and resistance to corrosion. The market is driven by the increasing demand for lightweight and fuel-efficient vehicles, advancements in automotive technology, and stringent regulations regarding vehicle safety and emissions. The global automotive structural sheet metal market is a critical segment of the automotive industry, influencing the design, performance, and sustainability of modern vehicles.

Galvanized Sheet Metal, High strength Sheet Metal, Aluminum Alloy Sheet Metal, Stainless Steel Sheet Metal, Titanium Alloy Sheet Metal, Others in the Global Automotive Structural Sheet Metal Market:

Galvanized sheet metal is a type of steel that has been coated with a layer of zinc to prevent rusting. This makes it highly durable and resistant to corrosion, which is essential for automotive applications where exposure to moisture and other environmental factors is common. High-strength sheet metal, on the other hand, is designed to withstand significant stress and strain without deforming. This type of metal is crucial for parts of the vehicle that need to absorb impact and provide structural integrity, such as the chassis and safety cages. Aluminum alloy sheet metal is known for its lightweight properties, which help in reducing the overall weight of the vehicle, thereby improving fuel efficiency and performance. Aluminum is also resistant to corrosion, making it a popular choice for both exterior and interior automotive components. Stainless steel sheet metal offers excellent resistance to rust and staining, making it ideal for parts that are exposed to harsh conditions. It is also known for its strength and durability, which are essential for maintaining the structural integrity of the vehicle. Titanium alloy sheet metal, although more expensive, provides an exceptional strength-to-weight ratio and is highly resistant to corrosion. This makes it suitable for high-performance and luxury vehicles where both performance and aesthetics are critical. Other types of sheet metals used in the automotive industry include various alloys and composites that offer specific advantages in terms of strength, weight, and resistance to environmental factors. Each type of sheet metal plays a unique role in the construction and performance of modern vehicles, contributing to the overall safety, efficiency, and durability of the automotive industry.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Structural Sheet Metal Market:

The usage of global automotive structural sheet metal in passenger vehicles and commercial vehicles varies significantly due to the different requirements and functions of these types of vehicles. In passenger vehicles, the primary focus is on safety, comfort, and fuel efficiency. The use of high-strength sheet metal in the chassis and safety cages helps to protect occupants in the event of a collision by absorbing impact and maintaining the structural integrity of the vehicle. Aluminum alloy sheet metal is often used in the body panels and other components to reduce weight, which in turn improves fuel efficiency and handling. Stainless steel and galvanized sheet metals are used in areas that are prone to rust and corrosion, such as the underbody and exhaust systems, to ensure longevity and durability. In commercial vehicles, the emphasis is on durability, load-bearing capacity, and cost-effectiveness. High-strength sheet metal is crucial for the chassis and frame to support heavy loads and withstand the rigors of daily use. Galvanized sheet metal is commonly used in commercial vehicles to prevent rust and corrosion, especially in parts that are exposed to harsh environmental conditions. Aluminum alloy sheet metal is also used in commercial vehicles, particularly in components where weight reduction can lead to improved fuel efficiency and payload capacity. Stainless steel is used in areas that require high durability and resistance to wear and tear, such as cargo areas and loading ramps. The use of titanium alloy sheet metal is less common in commercial vehicles due to its higher cost, but it may be used in specialized applications where its unique properties are required. Overall, the choice of sheet metal in both passenger and commercial vehicles is driven by the need to balance performance, safety, durability, and cost, ensuring that each vehicle meets the specific demands of its intended use.

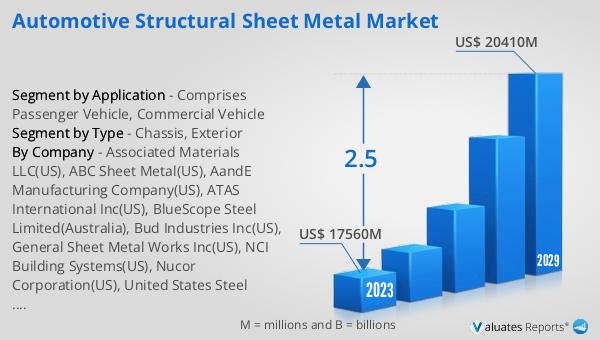

Global Automotive Structural Sheet Metal Market Outlook:

The global automotive structural sheet metal market was valued at $17.07 billion in 2023 and is projected to reach $20.41 billion by 2030, growing at a compound annual growth rate (CAGR) of 2.5% during the forecast period from 2024 to 2030. Currently, more than 90% of the world's automobiles are concentrated in three continents: Asia, Europe, and North America. Asia leads in automobile production, accounting for 56% of the global output, followed by Europe at 20%, and North America at 16%. This distribution highlights the significant role these regions play in the automotive industry and underscores the importance of the automotive structural sheet metal market in supporting the production and development of vehicles in these key areas. The market's growth is driven by the increasing demand for lightweight and fuel-efficient vehicles, advancements in automotive technology, and stringent regulations regarding vehicle safety and emissions. As the automotive industry continues to evolve, the demand for high-quality structural sheet metal will remain a critical factor in the production of safe, efficient, and durable vehicles.

| Report Metric | Details |

| Report Name | Automotive Structural Sheet Metal Market |

| Accounted market size in 2023 | US$ 17070 million |

| Forecasted market size in 2030 | US$ 20410 million |

| CAGR | 2.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | AandE Manufacturing Company(US), ABC Sheet Metal(US), Alcoa Inc(US), Aleris International, Amada, Associated Materials LLC(US), ATAS International Inc(US), Autoline Industries Ltd(India), BlueScope Steel Limited(Australia), Bud Industries Inc(US), Frank Dudley, General Sheet Metal Works Inc(US), General Stamping and Metal Works, Larsen Manufacturing, Mayville Engineering Company, NCI Building Systems(US), Noble Industries(US), Novelis, Nucor Corporation(US), O’Neal Manufacturing Services, Omax Autos, Paul Craemer GmbH, Prototek(India), United States Steel Corporation(US), Wise Alloys LLC(US) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |