What is Global AGV Handling Robot Market?

The Global AGV Handling Robot Market refers to the worldwide industry focused on the development, production, and deployment of Automated Guided Vehicles (AGVs) equipped with robotic handling capabilities. These robots are designed to transport materials and goods within various industrial settings without human intervention. They utilize advanced technologies such as sensors, cameras, and software to navigate and perform tasks autonomously. The market encompasses a wide range of AGV types, including those used in warehousing, logistics, manufacturing, and other sectors. The increasing demand for automation to enhance efficiency, reduce labor costs, and improve safety in industrial operations is driving the growth of this market. Companies across the globe are investing in AGV handling robots to streamline their processes and stay competitive in an ever-evolving industrial landscape. The market is characterized by continuous innovation, with manufacturers constantly developing new models and features to meet the diverse needs of different industries. As a result, the Global AGV Handling Robot Market is poised for significant growth in the coming years, reflecting the broader trend towards automation and smart manufacturing.

Jack-up Type AGV, Fork Type AGV in the Global AGV Handling Robot Market:

Jack-up Type AGVs and Fork Type AGVs are two prominent categories within the Global AGV Handling Robot Market, each serving distinct purposes and applications. Jack-up Type AGVs are designed to lift and transport loads by raising them off the ground. These AGVs are equipped with lifting mechanisms that allow them to pick up pallets, containers, or other items from the floor and move them to designated locations. They are commonly used in environments where precise positioning and handling of goods are required, such as in manufacturing plants and distribution centers. The ability to lift and transport heavy loads with minimal human intervention makes Jack-up Type AGVs an essential component in modern automated material handling systems. On the other hand, Fork Type AGVs are equipped with fork-like structures that enable them to handle pallets and other load carriers. These AGVs operate similarly to traditional forklifts but with the added advantage of autonomous navigation and operation. Fork Type AGVs are widely used in warehousing and logistics operations, where they can efficiently move goods from one location to another, load and unload trucks, and stack pallets in storage racks. The integration of advanced sensors and navigation systems allows these AGVs to operate safely and accurately in dynamic environments, reducing the risk of accidents and improving overall operational efficiency. Both Jack-up Type and Fork Type AGVs are integral to the automation strategies of many industries, helping to streamline material handling processes, reduce labor costs, and enhance productivity. As the demand for automation continues to rise, the adoption of these AGVs is expected to grow, further driving the expansion of the Global AGV Handling Robot Market.

Warehousing Industry, logistics Industry, Construction Site in the Global AGV Handling Robot Market:

The usage of AGV Handling Robots in the warehousing industry has revolutionized the way goods are stored, retrieved, and transported within warehouses. These robots are capable of autonomously navigating through warehouse aisles, picking up items from storage locations, and delivering them to designated areas for packing or shipping. This automation not only speeds up the order fulfillment process but also reduces the likelihood of errors and damages associated with manual handling. In the logistics industry, AGV Handling Robots play a crucial role in optimizing the movement of goods within distribution centers and between different stages of the supply chain. They can efficiently transport packages, pallets, and containers, ensuring timely and accurate deliveries. The ability to operate around the clock without the need for breaks or shifts makes these robots an invaluable asset in meeting the high demands of modern logistics operations. Additionally, AGV Handling Robots are increasingly being deployed in construction sites to enhance the efficiency and safety of material handling tasks. These robots can transport construction materials, tools, and equipment across the site, reducing the physical strain on workers and minimizing the risk of accidents. By automating repetitive and labor-intensive tasks, AGV Handling Robots allow construction workers to focus on more skilled and critical activities, ultimately improving overall project productivity. The versatility and adaptability of AGV Handling Robots make them suitable for a wide range of applications across different industries, driving their adoption and contributing to the growth of the Global AGV Handling Robot Market.

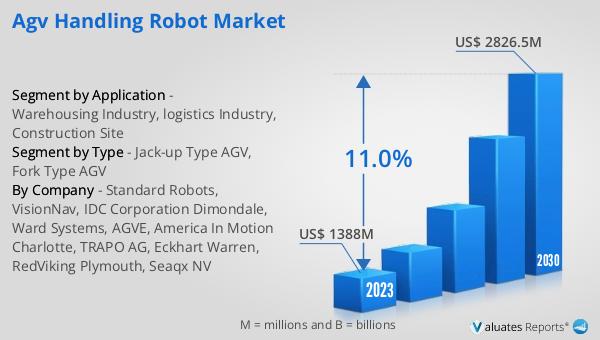

Global AGV Handling Robot Market Outlook:

The global AGV Handling Robot market was valued at US$ 1388 million in 2023 and is anticipated to reach US$ 2826.5 million by 2030, witnessing a CAGR of 11.0% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for automation and efficiency in various industrial sectors. Companies are recognizing the benefits of AGV Handling Robots in terms of cost savings, improved productivity, and enhanced safety. As a result, they are investing heavily in these technologies to stay competitive and meet the evolving needs of their operations. The market's robust growth trajectory is also driven by continuous advancements in robotics and automation technologies, which are making AGV Handling Robots more capable, reliable, and accessible. With the ongoing trend towards smart manufacturing and Industry 4.0, the adoption of AGV Handling Robots is expected to accelerate further, transforming the way industries operate and manage their material handling processes.

| Report Metric | Details |

| Report Name | AGV Handling Robot Market |

| Accounted market size in 2023 | US$ 1388 million |

| Forecasted market size in 2030 | US$ 2826.5 million |

| CAGR | 11.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Standard Robots, VisionNav, IDC Corporation Dimondale, Ward Systems, AGVE, America In Motion Charlotte, TRAPO AG, Eckhart Warren, RedViking Plymouth, Seaqx NV |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |