What is Global 3D Printed Polymers Market?

The Global 3D Printed Polymers Market is a rapidly evolving sector that leverages the capabilities of 3D printing technology to create objects from polymer materials. This market encompasses a wide range of applications, from prototyping to full-scale production, across various industries. Polymers, which include plastics, resins, and other materials, are favored for their versatility, durability, and cost-effectiveness. The market is driven by advancements in 3D printing technology, increasing demand for customized products, and the need for efficient manufacturing processes. As industries continue to explore the potential of 3D printing, the demand for high-quality polymers is expected to grow, making this market a crucial component of modern manufacturing and innovation.

Plastics, Resins, Others in the Global 3D Printed Polymers Market:

In the Global 3D Printed Polymers Market, plastics, resins, and other materials play a pivotal role. Plastics are the most commonly used materials due to their versatility, ease of use, and cost-effectiveness. They are used in a variety of applications, from consumer electronics to automotive parts. Common types of plastics used in 3D printing include ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), and PETG (Polyethylene Terephthalate Glycol). These materials are favored for their strength, flexibility, and ability to produce detailed and complex shapes. Resins, on the other hand, are used primarily in stereolithography (SLA) and digital light processing (DLP) 3D printing technologies. They offer high precision and smooth surface finishes, making them ideal for applications that require fine details, such as dental models, jewelry, and intricate prototypes. Resins can be further categorized into standard resins, tough resins, flexible resins, and castable resins, each offering unique properties to meet specific needs. Other materials in the 3D printed polymers market include composites and specialty polymers. Composites are materials made from two or more constituent materials with different physical or chemical properties. They are designed to achieve a combination of properties that are not possible with individual materials alone. For example, carbon fiber-reinforced polymers are used in applications that require high strength and low weight, such as aerospace and automotive components. Specialty polymers, such as high-performance thermoplastics, are used in demanding applications that require exceptional mechanical properties, chemical resistance, and thermal stability. These materials are often used in the aerospace, automotive, and medical industries, where performance and reliability are critical. The choice of material in 3D printing depends on various factors, including the intended application, desired properties, and cost considerations. As the technology continues to advance, new materials are being developed to meet the evolving needs of different industries. This ongoing innovation is driving the growth of the Global 3D Printed Polymers Market, enabling manufacturers to produce high-quality, customized products with greater efficiency and precision.

Consumer Electronics, Manufacturing, Healthcare, Packaging, Aerospace, Automotive, Others in the Global 3D Printed Polymers Market:

The usage of Global 3D Printed Polymers Market spans across several key industries, each benefiting from the unique advantages of 3D printing technology. In consumer electronics, 3D printed polymers are used to create custom components, housings, and prototypes. This allows for rapid prototyping and iterative design processes, enabling companies to bring new products to market faster. In manufacturing, 3D printed polymers are used to produce jigs, fixtures, and tooling, which can significantly reduce production time and costs. The ability to create complex geometries and lightweight structures also makes 3D printing an attractive option for manufacturing applications. In the healthcare sector, 3D printed polymers are used to create custom implants, prosthetics, and medical devices. The ability to produce patient-specific solutions improves the fit and functionality of these devices, leading to better patient outcomes. Additionally, 3D printing is used to create anatomical models for surgical planning and training, enhancing the precision and effectiveness of medical procedures. In the packaging industry, 3D printed polymers are used to create custom packaging solutions, prototypes, and molds. This allows for greater flexibility and creativity in packaging design, as well as faster turnaround times. In the aerospace industry, 3D printed polymers are used to produce lightweight components, reducing the overall weight of aircraft and improving fuel efficiency. The ability to create complex, high-performance parts also makes 3D printing an attractive option for aerospace applications. In the automotive industry, 3D printed polymers are used to create custom parts, prototypes, and tooling. This allows for faster design iterations and reduced production costs, as well as the ability to produce lightweight and high-performance components. Other industries, such as fashion, architecture, and education, also benefit from the versatility and efficiency of 3D printed polymers. The ability to create customized, high-quality products with greater precision and speed is driving the adoption of 3D printing technology across a wide range of applications.

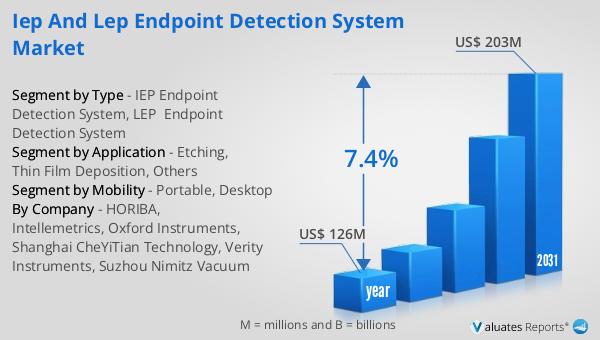

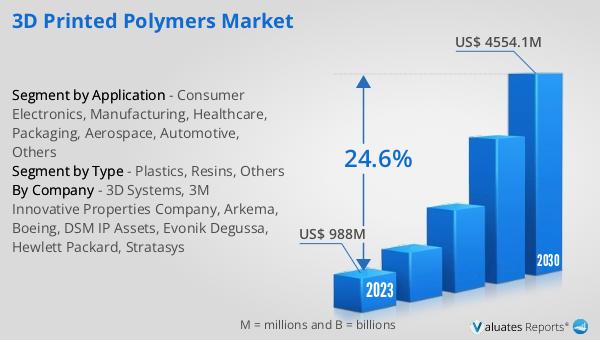

Global 3D Printed Polymers Market Outlook:

The global 3D Printed Polymers market was valued at US$ 988 million in 2023 and is anticipated to reach US$ 4554.1 million by 2030, witnessing a CAGR of 24.6% during the forecast period 2024-2030. This significant growth reflects the increasing adoption of 3D printing technology across various industries and the rising demand for high-quality polymer materials. The versatility and efficiency of 3D printing make it an attractive option for manufacturers looking to produce customized products with greater precision and speed. As the technology continues to advance, new materials and applications are being developed, further driving the growth of the market. The ability to create complex geometries, lightweight structures, and high-performance components is particularly appealing to industries such as aerospace, automotive, healthcare, and consumer electronics. Additionally, the cost-effectiveness and reduced production times associated with 3D printing are encouraging more companies to invest in this technology. The market's rapid expansion is also supported by ongoing research and development efforts aimed at improving the properties and performance of 3D printed polymers. As a result, the Global 3D Printed Polymers Market is poised for continued growth, offering new opportunities for innovation and efficiency in manufacturing and product development.

| Report Metric | Details |

| Report Name | 3D Printed Polymers Market |

| Accounted market size in 2023 | US$ 988 million |

| Forecasted market size in 2030 | US$ 4554.1 million |

| CAGR | 24.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3D Systems, 3M Innovative Properties Company, Arkema, Boeing, DSM IP Assets, Evonik Degussa, Hewlett Packard, Stratasys |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |