What is Robot Spraying Concrete System - Global Market?

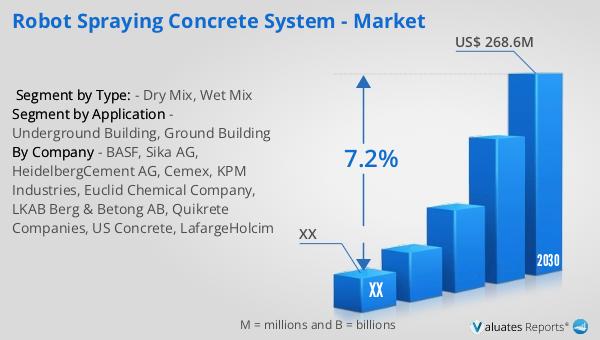

The Robot Spraying Concrete System represents a cutting-edge segment within the global market, characterized by its innovative approach to applying concrete. This system, leveraging robotic technology, offers a more efficient, precise, and cost-effective method of concrete application compared to traditional manual methods. As of 2023, the market value for this technology stood at approximately US$ 163 million, showcasing its emerging significance in the construction industry. With an anticipated compound annual growth rate (CAGR) of 7.2%, the market is expected to reach a valuation of US$ 268.6 million by the year 2030. This growth trajectory underscores the increasing adoption and reliance on robotic systems for concrete spraying tasks across various construction projects worldwide. The system's ability to enhance productivity, reduce labor costs, and improve the quality of construction work has positioned it as a pivotal innovation in the field, promising a transformative impact on global construction practices moving forward.

Dry Mix, Wet Mix in the Robot Spraying Concrete System - Global Market:

In the realm of Robot Spraying Concrete Systems on a global scale, two primary methodologies stand out: Dry Mix and Wet Mix. These techniques represent the foundational approaches utilized in robotic concrete spraying operations, each with its distinct characteristics and applications. The Dry Mix method involves the dry mixing of concrete components, which are then transported pneumatically through a hose to the nozzle, where water is added just before application. This method is prized for its flexibility and control over the water-cement ratio, allowing for adjustments on-the-fly based on specific project requirements. Conversely, the Wet Mix method entails pre-mixing water with the concrete materials before pumping the mixture through the hose to the nozzle for spraying. This approach is often favored for its consistency in mixture quality and the ability to pump over longer distances without segregation of materials. Both methods leverage robotic technology to enhance precision, reduce material wastage, and improve the overall efficiency of concrete spraying tasks. As the global market for Robot Spraying Concrete Systems continues to expand, the choice between Dry Mix and Wet Mix methods will largely depend on project-specific factors such as the required finish quality, work speed, and environmental considerations.

Underground Building, Ground Building in the Robot Spraying Concrete System - Global Market:

The utilization of Robot Spraying Concrete Systems in the global market has significantly transformed construction practices, especially in the areas of Underground and Ground Building construction. In underground construction, such as tunnels and subways, the robotic spraying of concrete offers unparalleled advantages in terms of speed, safety, and structural integrity. The precision and efficiency of robotic systems allow for the uniform application of concrete, crucial for the stability and durability of underground structures. Moreover, the automation minimizes human exposure to hazardous conditions, enhancing safety protocols. On the other hand, in ground building construction, these systems facilitate the rapid erection of structures, from residential buildings to commercial complexes. The adaptability of robotic spraying technology to various design specifications and the ability to work in constrained spaces make it an invaluable tool in modern construction. The consistent quality of sprayed concrete achieved through robotic application ensures the longevity and resilience of buildings, catering to the growing demand for sustainable construction practices. As the global market for Robot Spraying Concrete Systems evolves, its application in both underground and ground building construction is poised to redefine industry standards, promising a future where construction is not only faster and safer but also environmentally conscious.

Robot Spraying Concrete System - Global Market Outlook:

The market outlook for the Robot Spraying Concrete System globally presents a promising future. In 2023, the market's valuation was recorded at US$ 163 million, demonstrating its emerging role in the construction industry's technological advancement. The forecast suggests a significant growth trajectory, with expectations to reach US$ 268.6 million by 2030. This growth, at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030, indicates a robust expansion of the market. Such growth is reflective of the increasing adoption of robotic technology in construction practices, driven by the need for efficiency, precision, and cost-effectiveness. The Robot Spraying Concrete System is at the forefront of this transformation, offering innovative solutions that enhance construction quality and productivity. As the market continues to evolve, it is set to redefine construction methodologies, making a substantial impact on the global construction industry's future.

| Report Metric | Details |

| Report Name | Robot Spraying Concrete System - Market |

| Forecasted market size in 2030 | US$ 268.6 million |

| CAGR | 7.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BASF, Sika AG, HeidelbergCement AG, Cemex, KPM Industries, Euclid Chemical Company, LKAB Berg & Betong AB, Quikrete Companies, US Concrete, LafargeHolcim |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |