What is Operation and Maintenance Load Monitoring System - Global Market?

The Operation and Maintenance Load Monitoring System global market is a sophisticated arena that focuses on the provision of crucial data regarding the load operations across various industries. This system plays a pivotal role in ensuring the efficiency, safety, and longevity of machinery and equipment by continuously monitoring and analyzing the load exerted on them. Essentially, it helps in preventing overloading and underloading, which can lead to equipment failure or inefficient operation. With the advent of advanced technologies, these systems have become more precise and reliable, offering real-time insights and alerts to prevent potential hazards. The global market for these systems is significant, given their importance across a wide range of industries including manufacturing, construction, and transportation. As industries strive for optimization and safety, the demand for operation and maintenance load monitoring systems is expected to surge, reflecting the system's integral role in modern industrial operations. This market's growth is driven by the increasing awareness among businesses about the benefits of maintaining proper load management to enhance operational efficiency and extend the lifespan of equipment.

Analog Load Cell, Digital Load Cell in the Operation and Maintenance Load Monitoring System - Global Market:

Diving into the specifics, the Operation and Maintenance Load Monitoring System global market is segmented into analog and digital load cells, each playing a unique role in load monitoring. Analog load cells, known for their simplicity and reliability, convert physical force into an electrical signal that can be measured. They are widely used in various industries due to their cost-effectiveness and ease of integration into existing systems. On the other hand, digital load cells offer a more sophisticated approach to load monitoring. These devices not only measure weight but also process data within the cell itself, providing more accurate and faster readings. Digital load cells are equipped with communication capabilities, allowing for easy integration into modern IoT (Internet of Things) systems for real-time monitoring and analysis. This digital advancement enhances predictive maintenance capabilities, making it possible to anticipate equipment failures before they occur, thereby reducing downtime and maintenance costs. The global market's shift towards digitalization has seen a growing preference for digital load cells, attributed to their enhanced accuracy, reliability, and the ability to seamlessly integrate with advanced monitoring systems. This transition is reflective of the broader industrial move towards automation and data-driven decision-making, positioning digital load cells as a critical component in the future of operation and maintenance load monitoring systems.

Automobile Industry, Healthcare Industry, Construction Industry in the Operation and Maintenance Load Monitoring System - Global Market:

In the realm of the Operation and Maintenance Load Monitoring System global market, its application across the automobile, healthcare, and construction industries showcases its versatility and critical importance. In the automobile industry, these systems ensure the precise assembly of vehicles, monitoring the load on various components to guarantee safety and reliability. This precision is crucial in maintaining the integrity of the vehicle's structure and performance. In healthcare, load monitoring systems play a vital role in patient care equipment, such as surgical tables and patient lifts, ensuring safety and functionality. The accurate measurement of load can significantly impact the quality of care and the safety of both patients and healthcare providers. Meanwhile, in the construction industry, these systems are indispensable for monitoring the load on structures during construction to prevent overloading and potential collapse. They ensure that the materials and structures can withstand the intended load, adhering to safety standards and regulations. The application of operation and maintenance load monitoring systems in these industries not only enhances safety and efficiency but also contributes to the longevity and reliability of equipment and structures, underscoring the system's value across diverse sectors.

Operation and Maintenance Load Monitoring System - Global Market Outlook:

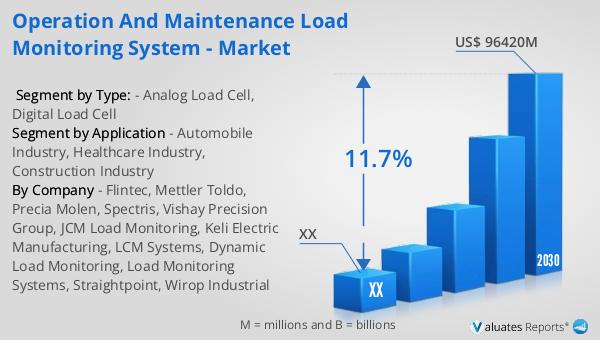

The market outlook for the Operation and Maintenance Load Monitoring System global market presents a promising future. In 2023, the market's value was estimated at approximately $44,640 million, showcasing its significant role across various industries. Looking ahead, projections indicate a substantial growth, with the market expected to reach around $96,420 million by the year 2030. This growth trajectory, characterized by a Compound Annual Growth Rate (CAGR) of 11.7% from 2024 to 2030, underscores the increasing reliance on and demand for these systems. The anticipated expansion reflects the growing recognition of the importance of load monitoring in maintaining operational efficiency, safety, and equipment longevity. As industries continue to evolve and prioritize these aspects, the Operation and Maintenance Load Monitoring System market is set to witness substantial growth, highlighting its critical role in the future of industrial operations.

| Report Metric | Details |

| Report Name | Operation and Maintenance Load Monitoring System - Market |

| Forecasted market size in 2030 | US$ 96420 million |

| CAGR | 11.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flintec, Mettler Toldo, Precia Molen, Spectris, Vishay Precision Group, JCM Load Monitoring, Keli Electric Manufacturing, LCM Systems, Dynamic Load Monitoring, Load Monitoring Systems, Straightpoint, Wirop Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |