What is Non-spill Coupling - Global Market?

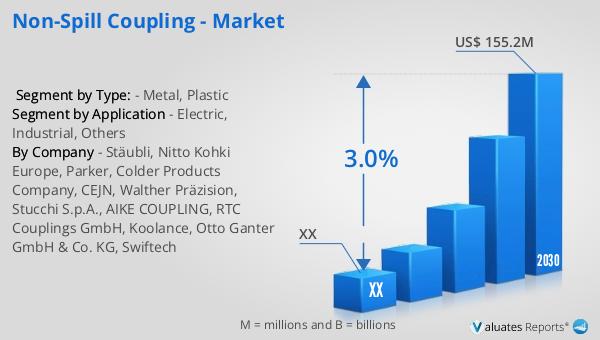

In the realm of fluid and gas transfer, the non-spill coupling market is a critical segment that ensures efficient, leak-free connections between hoses or pipes. This technology is particularly designed to prevent spills and leaks, which can be costly and hazardous, especially in industries dealing with volatile or sensitive substances. Non-spill couplings, also known as dry break couplings, automatically seal off the flow of fluid or gas when disconnected, minimizing the risk of spillage. The global market for non-spill couplings has been recognized for its importance across various sectors, including automotive, chemical, pharmaceutical, and oil & gas industries, among others. As of 2023, the market was valued at approximately US$ 126 million and is anticipated to grow to US$ 155.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0%. This growth is attributed to increasing industrialization, stringent environmental regulations, and the rising demand for safer fluid handling solutions across the globe.

Metal, Plastic in the Non-spill Coupling - Global Market:

The non-spill coupling market is broadly categorized into metal and plastic-based couplings, each serving distinct purposes across various industries. Metal couplings, made from materials such as steel, brass, and aluminum, are favored for their durability, resistance to high temperatures, and compatibility with a wide range of chemicals. They are commonly used in environments that require robust performance, such as in the oil and gas sector, where the risk of corrosion and the need for high-pressure handling are significant. On the other hand, plastic-based non-spill couplings are lightweight, cost-effective, and resistant to chemical corrosion, making them suitable for applications in the pharmaceutical, food and beverage, and chemical processing industries. These couplings are typically made from materials like polypropylene, PVDF, and nylon, offering excellent resistance to aggressive chemicals and environments where metal couplings might not be suitable. The choice between metal and plastic non-spill couplings depends on the specific requirements of the application, including chemical compatibility, pressure ratings, and environmental conditions. As the global market continues to expand, the demand for both metal and plastic non-spill couplings is expected to rise, driven by the growing need for safe and efficient fluid handling solutions across a broad spectrum of industries.

Electric, Industrial, Others in the Non-spill Coupling - Global Market:

Non-spill couplings play a pivotal role in various sectors, including electric, industrial, and others, by providing secure and efficient connections for the transfer of fluids and gases. In the electric sector, these couplings are utilized in cooling systems for batteries and electronic components, where precise temperature control and leak prevention are crucial for maintaining performance and safety. The industrial sector benefits significantly from non-spill couplings, as they are employed in hydraulic systems, fuel lines, and chemical processing, where preventing spills is essential to protect workers and the environment while ensuring uninterrupted operations. Other areas where non-spill couplings find applications include agriculture for pesticide and fertilizer distribution systems, the automotive industry for fuel and brake line connections, and the medical field for the safe handling of fluids and gases in various devices and equipment. The versatility and reliability of non-spill couplings make them indispensable in these sectors, contributing to their growing demand in the global market. The emphasis on safety, environmental protection, and operational efficiency across these industries continues to drive the adoption of non-spill coupling solutions worldwide.

Non-spill Coupling - Global Market Outlook:

The outlook for the non-spill coupling market globally presents a promising future, with the sector valued at US$ 126 million in 2023 and projected to reach US$ 155.2 million by 2030. This growth trajectory, representing a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030, underscores the increasing demand for these essential components across various industries. In North America, a significant market for non-spill couplings, the industry's value in 2023 sets the stage for continued expansion, with expectations to achieve substantial growth by 2030. This anticipated growth is fueled by the critical role non-spill couplings play in ensuring safe, efficient fluid and gas transfer in numerous applications, from industrial manufacturing processes to the automotive and energy sectors. The market's expansion is further supported by technological advancements in coupling design and materials, enhancing their performance and broadening their applicability. As industries worldwide strive for greater operational efficiency and environmental compliance, the demand for non-spill couplings is set to rise, marking a period of robust growth for the market in the coming years.

| Report Metric | Details |

| Report Name | Non-spill Coupling - Market |

| Forecasted market size in 2030 | US$ 155.2 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stäubli, Nitto Kohki Europe, Parker, Colder Products Company, CEJN, Walther Präzision, Stucchi S.p.A., AIKE COUPLING, RTC Couplings GmbH, Koolance, Otto Ganter GmbH & Co. KG, Swiftech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |