What is Global Type IV Composite Pressure Vessel Market?

The Global Type IV Composite Pressure Vessel Market refers to the industry focused on the production and distribution of advanced pressure vessels made from composite materials. These vessels are primarily used for storing gases like compressed natural gas (CNG), liquefied petroleum gas (LPG), and hydrogen. Type IV composite pressure vessels are unique because they have a plastic liner fully wrapped with a carbon fiber or glass fiber composite, making them lightweight yet incredibly strong. This combination of materials allows these vessels to withstand high pressures while being significantly lighter than traditional metal pressure vessels. The market for these advanced storage solutions is growing due to the increasing demand for alternative fuel vehicles, which require efficient and safe storage of high-pressure gases. Additionally, the push for cleaner energy solutions and the need for lightweight, durable storage options in various industries are driving the adoption of Type IV composite pressure vessels globally.

Carbon Fiber, Glass Fiber, Other in the Global Type IV Composite Pressure Vessel Market:

Carbon fiber, glass fiber, and other materials play crucial roles in the Global Type IV Composite Pressure Vessel Market. Carbon fiber is highly valued for its exceptional strength-to-weight ratio, making it an ideal material for pressure vessels that need to withstand high pressures while remaining lightweight. This material is composed of thin, strong crystalline filaments of carbon, which are woven together to form a fabric that can be molded into various shapes. The resulting composite material is not only strong but also resistant to corrosion and fatigue, which are critical factors for pressure vessels used in demanding environments. Glass fiber, on the other hand, is a more cost-effective alternative to carbon fiber. While it doesn't offer the same level of strength and weight advantages, it still provides significant benefits over traditional metal pressure vessels. Glass fiber composites are made from fine fibers of glass that are woven into a fabric and then combined with a resin to form a strong, durable material. These composites are also resistant to corrosion and can handle high pressures, making them suitable for many applications where cost is a significant consideration. Other materials used in the production of Type IV composite pressure vessels include aramid fibers and hybrid composites. Aramid fibers, such as Kevlar, offer excellent impact resistance and are often used in applications where safety is a primary concern. Hybrid composites combine different types of fibers, such as carbon and glass, to create a material that balances cost, weight, and strength. These hybrid materials can be tailored to meet specific performance requirements, making them versatile options for various applications. The choice of material for a Type IV composite pressure vessel depends on several factors, including the intended use, required performance characteristics, and budget constraints. For instance, carbon fiber composites are often chosen for high-performance applications where weight savings and strength are critical, such as in the automotive and aerospace industries. Glass fiber composites, being more affordable, are commonly used in applications where cost is a more significant factor, such as in residential and commercial gas storage. Aramid fibers and hybrid composites are selected for specialized applications that require specific performance attributes, such as impact resistance or a balance of cost and strength. The manufacturing process for these composite materials involves several steps, including fiber weaving, resin impregnation, and curing. The fibers are first woven into a fabric, which is then impregnated with a resin to form a composite material. This material is then molded into the desired shape and cured to harden the resin, creating a strong, durable pressure vessel. Advances in manufacturing techniques and materials science are continually improving the performance and cost-effectiveness of these composite materials, driving their adoption in the Global Type IV Composite Pressure Vessel Market.

CNG Storage Tank, LPG Storage Tank, Hydrogen Storage Tank, Others in the Global Type IV Composite Pressure Vessel Market:

The Global Type IV Composite Pressure Vessel Market finds extensive usage in various areas, including CNG storage tanks, LPG storage tanks, hydrogen storage tanks, and others. In the realm of CNG storage tanks, Type IV composite pressure vessels are highly valued for their lightweight and high-strength properties. Compressed natural gas is stored at high pressures, and the use of composite materials ensures that the storage tanks can withstand these pressures without adding excessive weight. This is particularly important for automotive applications, where reducing the weight of the vehicle can lead to improved fuel efficiency and performance. The lightweight nature of these tanks also makes them easier to handle and install, further enhancing their appeal for CNG storage. For LPG storage tanks, the benefits of Type IV composite pressure vessels are similar. Liquefied petroleum gas is stored under pressure, and the use of composite materials helps to ensure that the storage tanks are both strong and lightweight. This is especially important in residential and commercial applications, where ease of installation and handling are critical considerations. The corrosion resistance of composite materials also makes them an attractive option for LPG storage, as they can withstand the harsh conditions often encountered in these environments. Hydrogen storage tanks represent another significant application area for Type IV composite pressure vessels. Hydrogen is stored at very high pressures, and the lightweight, high-strength properties of composite materials make them ideal for this purpose. The use of composite pressure vessels in hydrogen storage is particularly important for the development of hydrogen fuel cell vehicles, where weight savings can lead to improved vehicle range and performance. Additionally, the safety and durability of composite materials are crucial for ensuring the safe storage and transport of hydrogen, which is a highly flammable gas. Other applications of Type IV composite pressure vessels include their use in various industrial and commercial settings where high-pressure gas storage is required. These can range from storage solutions for industrial gases used in manufacturing processes to portable gas storage for emergency and backup power systems. The versatility of composite materials allows these pressure vessels to be tailored to meet the specific needs of different applications, providing a reliable and efficient solution for high-pressure gas storage across a wide range of industries. The adoption of Type IV composite pressure vessels in these various applications is driven by the need for lightweight, durable, and safe storage solutions. The unique properties of composite materials, including their high strength-to-weight ratio, corrosion resistance, and ability to withstand high pressures, make them an ideal choice for these demanding applications. As industries continue to seek more efficient and sustainable solutions for high-pressure gas storage, the use of Type IV composite pressure vessels is expected to grow, further solidifying their importance in the global market.

Global Type IV Composite Pressure Vessel Market Outlook:

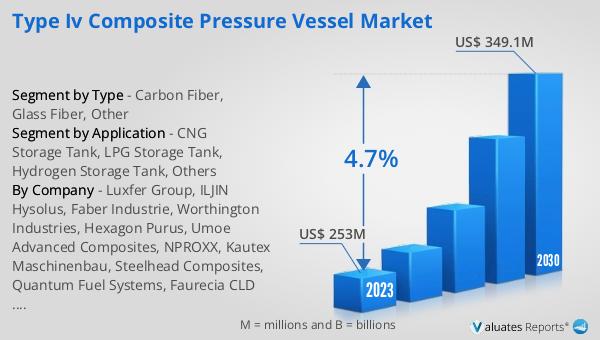

The global Type IV Composite Pressure Vessel market was valued at US$ 253 million in 2023 and is anticipated to reach US$ 349.1 million by 2030, witnessing a CAGR of 4.7% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for advanced pressure vessels that offer a combination of lightweight and high-strength properties. The market's expansion is driven by the rising adoption of alternative fuel vehicles, which require efficient and safe storage solutions for high-pressure gases like CNG, LPG, and hydrogen. Additionally, the push for cleaner energy solutions and the need for durable, corrosion-resistant storage options in various industries are contributing to the market's growth. The use of composite materials, such as carbon fiber and glass fiber, in the production of these pressure vessels is a key factor in their growing popularity. These materials provide significant advantages over traditional metal pressure vessels, including reduced weight, improved strength, and enhanced resistance to corrosion and fatigue. As a result, Type IV composite pressure vessels are becoming the preferred choice for high-pressure gas storage in a wide range of applications, from automotive and aerospace to residential and commercial gas storage. The market's positive outlook is further supported by ongoing advancements in materials science and manufacturing techniques, which are continually improving the performance and cost-effectiveness of composite pressure vessels. As industries continue to seek more efficient and sustainable solutions for high-pressure gas storage, the demand for Type IV composite pressure vessels is expected to grow, driving the market's expansion in the coming years.

| Report Metric | Details |

| Report Name | Type IV Composite Pressure Vessel Market |

| Accounted market size in 2023 | US$ 253 million |

| Forecasted market size in 2030 | US$ 349.1 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Luxfer Group, ILJIN Hysolus, Faber Industrie, Worthington Industries, Hexagon Purus, Umoe Advanced Composites, NPROXX, Kautex Maschinenbau, Steelhead Composites, Quantum Fuel Systems, Faurecia CLD Safety Technology (Shenyang), Beijing Tianhai Industry, Shandong Auyan New Energy Technology, Sinoma Science & Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |