What is Global Roll-Annealed (RA) Copper Foil Market?

The Global Roll-Annealed (RA) Copper Foil Market is a specialized segment within the broader copper foil industry, focusing on the production and distribution of roll-annealed copper foil. This type of copper foil is created through a process that involves rolling and annealing, which enhances its mechanical properties, making it more suitable for various high-performance applications. Roll-annealed copper foil is known for its excellent ductility, high tensile strength, and superior conductivity, making it a preferred choice in industries that require reliable and efficient electrical and thermal performance. The market for RA copper foil is driven by its extensive use in electronics, automotive, and energy storage sectors, among others. As technology advances and the demand for more efficient and compact electronic devices grows, the need for high-quality RA copper foil is expected to increase. This market is characterized by a high level of competition among key players who are continually innovating to improve the quality and performance of their products.

TPC Copper Foil, HA Copper Foil, HS Copper Foil in the Global Roll-Annealed (RA) Copper Foil Market:

TPC Copper Foil, HA Copper Foil, and HS Copper Foil are three distinct types of copper foils that play significant roles in the Global Roll-Annealed (RA) Copper Foil Market. TPC Copper Foil, or Tough-Pitch Copper Foil, is known for its high electrical conductivity and excellent thermal properties. It is widely used in applications where efficient heat dissipation and electrical performance are critical, such as in power transformers and high-frequency circuits. The manufacturing process of TPC Copper Foil involves a series of rolling and annealing steps that enhance its mechanical strength and flexibility, making it suitable for complex electronic components. HA Copper Foil, or High-Accuracy Copper Foil, is designed for applications that require precise thickness control and uniformity. This type of copper foil is often used in the production of high-density interconnect (HDI) printed circuit boards (PCBs) and other advanced electronic devices. The high accuracy in thickness ensures consistent performance and reliability in these applications. HA Copper Foil is also known for its excellent surface finish, which is crucial for the adhesion of other materials in multilayer PCBs. HS Copper Foil, or High-Strength Copper Foil, is characterized by its superior tensile strength and durability. This type of copper foil is ideal for applications that demand high mechanical performance, such as in automotive and aerospace industries. The high strength of HS Copper Foil allows it to withstand harsh environmental conditions and mechanical stresses, ensuring long-term reliability and performance. The production process of HS Copper Foil involves advanced rolling and annealing techniques that enhance its grain structure and mechanical properties. In the Global Roll-Annealed (RA) Copper Foil Market, these three types of copper foils cater to different needs and applications, each offering unique properties that make them suitable for specific uses. The continuous innovation and development in the production processes of TPC, HA, and HS Copper Foils are driving the growth and diversification of the RA copper foil market.

Copper Clad Laminate, Printed Circuit Boards, Li-ion Battery in the Global Roll-Annealed (RA) Copper Foil Market:

The usage of Global Roll-Annealed (RA) Copper Foil Market spans several critical areas, including Copper Clad Laminate, Printed Circuit Boards, and Li-ion Batteries. In the production of Copper Clad Laminate (CCL), RA copper foil is used as a conductive layer that is bonded to a non-conductive substrate, typically made of fiberglass or other insulating materials. The high conductivity and excellent mechanical properties of RA copper foil make it an ideal choice for CCL, which is a fundamental component in the manufacturing of PCBs. The uniform thickness and superior surface finish of RA copper foil ensure reliable electrical performance and efficient heat dissipation in CCL applications. In Printed Circuit Boards (PCBs), RA copper foil is used to create the conductive pathways that connect various electronic components. The high ductility and tensile strength of RA copper foil allow it to be easily etched and patterned to form intricate circuit designs. This is particularly important in the production of high-density interconnect (HDI) PCBs, where precise and reliable electrical connections are crucial. The use of RA copper foil in PCBs enhances the overall performance and reliability of electronic devices, making it a preferred choice in the electronics industry. In Li-ion Batteries, RA copper foil is used as a current collector in the anode, playing a critical role in the battery's performance and efficiency. The high conductivity and excellent mechanical properties of RA copper foil ensure efficient charge and discharge cycles, contributing to the overall energy density and lifespan of the battery. The uniform thickness and superior surface finish of RA copper foil also enhance the adhesion of active materials, improving the battery's overall performance. The use of RA copper foil in Li-ion batteries is particularly important in applications that require high energy density and long cycle life, such as in electric vehicles and portable electronic devices. The versatility and superior properties of RA copper foil make it an essential material in these critical applications, driving the growth and demand in the Global Roll-Annealed (RA) Copper Foil Market.

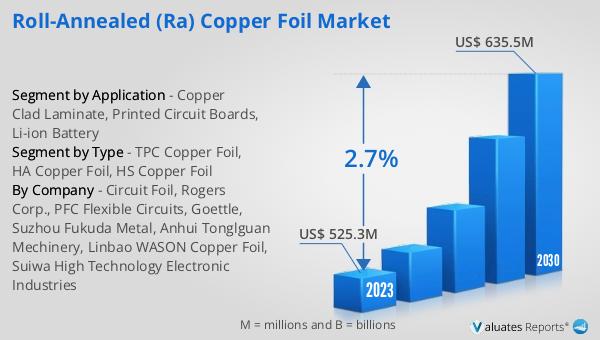

Global Roll-Annealed (RA) Copper Foil Market Outlook:

The global Roll-Annealed (RA) Copper Foil market was valued at US$ 525.3 million in 2023 and is anticipated to reach US$ 635.5 million by 2030, witnessing a CAGR of 2.7% during the forecast period 2024-2030. China is the largest Rolled Annealed Copper Foil market with about 38% market share. Japan is the follower accounting for about 21% market share. Top 3 companies occupied about 64% market share.

| Report Metric | Details |

| Report Name | Roll-Annealed (RA) Copper Foil Market |

| Accounted market size in 2023 | US$ 525.3 million |

| Forecasted market size in 2030 | US$ 635.5 million |

| CAGR | 2.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Circuit Foil, Rogers Corp., PFC Flexible Circuits, Goettle, Suzhou Fukuda Metal, Anhui Tonglguan Mechinery, Linbao WASON Copper Foil, Suiwa High Technology Electronic Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |