What is Global Oil and Gas Drill Bit Market?

The Global Oil and Gas Drill Bit Market is a crucial segment within the oil and gas industry, focusing on the tools used to drill into the earth to extract oil and gas. Drill bits are essential for creating the boreholes that allow for the extraction of these valuable resources. The market encompasses various types of drill bits, including fixed cutter bits and roller cone bits, each designed for specific drilling conditions and rock formations. The demand for these drill bits is driven by the ongoing need for energy, advancements in drilling technology, and the exploration of new oil and gas reserves. The market is influenced by factors such as oil prices, technological innovations, and geopolitical events that impact the global energy landscape. Companies operating in this market continuously invest in research and development to improve the efficiency and durability of their drill bits, aiming to reduce drilling costs and enhance the overall productivity of oil and gas extraction operations. The market's growth is also supported by the increasing exploration activities in both onshore and offshore regions, as well as the rising demand for energy in developing economies.

Fixed Cutter Bits, Roller Cone Bits in the Global Oil and Gas Drill Bit Market:

Fixed cutter bits and roller cone bits are two primary types of drill bits used in the global oil and gas industry, each with distinct characteristics and applications. Fixed cutter bits, also known as PDC (polycrystalline diamond compact) bits, are designed with a solid body and cutting elements that are fixed in place. These bits are highly efficient in drilling through soft to medium-hard formations and are known for their durability and long lifespan. The cutting elements, typically made of synthetic diamond or tungsten carbide, provide excellent wear resistance and maintain their sharpness over extended periods. Fixed cutter bits are particularly effective in high-speed drilling operations and are widely used in both onshore and offshore drilling projects. Their design allows for a smoother drilling process, reducing the risk of bit failure and minimizing downtime. On the other hand, roller cone bits, also known as tri-cone bits, consist of three rotating cones with cutting teeth that crush and grind the rock as the bit rotates. These bits are versatile and can handle a wide range of rock formations, from soft to extremely hard. The cones are mounted on bearings, allowing them to rotate independently and adapt to the varying hardness of the rock. Roller cone bits are known for their ability to handle high-impact drilling conditions and are often used in challenging environments where fixed cutter bits may not be as effective. The design of roller cone bits allows for efficient removal of cuttings from the borehole, reducing the risk of clogging and improving drilling performance. Both fixed cutter bits and roller cone bits play a vital role in the global oil and gas drill bit market, catering to different drilling needs and conditions. The choice between the two types of bits depends on various factors, including the geological characteristics of the drilling site, the desired drilling speed, and the overall cost considerations. Companies in the oil and gas industry often use a combination of both types of bits to optimize their drilling operations and achieve the best results. The continuous advancements in drill bit technology, such as the development of hybrid bits that combine the features of fixed cutter and roller cone bits, further enhance the efficiency and versatility of drilling operations. These innovations contribute to the overall growth and competitiveness of the global oil and gas drill bit market, enabling companies to explore new reserves and meet the increasing demand for energy.

Offshore, Onshore in the Global Oil and Gas Drill Bit Market:

The usage of drill bits in the global oil and gas market varies significantly between offshore and onshore drilling operations, each presenting unique challenges and requirements. Offshore drilling involves extracting oil and gas from beneath the ocean floor, often at great depths and under high-pressure conditions. The drill bits used in offshore drilling must be highly durable and capable of withstanding extreme environments. Fixed cutter bits are commonly used in offshore drilling due to their efficiency and ability to maintain sharpness over long periods. These bits are ideal for drilling through the soft to medium-hard formations typically found in offshore reservoirs. The smooth drilling process provided by fixed cutter bits reduces the risk of equipment failure and minimizes downtime, which is crucial in the costly and complex offshore drilling operations. Roller cone bits are also used in offshore drilling, particularly in harder rock formations where their crushing and grinding action is more effective. The versatility of roller cone bits allows them to handle the varying geological conditions encountered in offshore drilling, making them a valuable tool in the exploration and extraction of underwater oil and gas reserves. The ability of roller cone bits to efficiently remove cuttings from the borehole is especially important in offshore drilling, where maintaining a clean and stable borehole is critical to the success of the operation. The advancements in drill bit technology, such as the development of hybrid bits, further enhance the efficiency and reliability of offshore drilling operations, enabling companies to explore deeper and more challenging reservoirs. Onshore drilling, on the other hand, involves extracting oil and gas from land-based reservoirs. The geological conditions in onshore drilling can vary widely, from soft sedimentary formations to hard crystalline rocks. Fixed cutter bits are widely used in onshore drilling due to their durability and high drilling speed. These bits are particularly effective in drilling through the soft to medium-hard formations commonly found in onshore reservoirs. The long lifespan of fixed cutter bits reduces the need for frequent bit changes, improving the overall efficiency and cost-effectiveness of onshore drilling operations. The ability of fixed cutter bits to maintain their sharpness over extended periods also contributes to the smooth and continuous drilling process, minimizing downtime and enhancing productivity. Roller cone bits are also extensively used in onshore drilling, especially in harder rock formations where their crushing and grinding action is more effective. The versatility of roller cone bits allows them to handle a wide range of geological conditions, making them a valuable tool in the exploration and extraction of onshore oil and gas reserves. The efficient removal of cuttings provided by roller cone bits is crucial in maintaining a clean and stable borehole, which is essential for the success of onshore drilling operations. The continuous advancements in drill bit technology, such as the development of hybrid bits, further enhance the efficiency and reliability of onshore drilling operations, enabling companies to explore new reserves and meet the increasing demand for energy. In summary, the usage of drill bits in the global oil and gas market is essential for both offshore and onshore drilling operations. The choice between fixed cutter bits and roller cone bits depends on various factors, including the geological characteristics of the drilling site, the desired drilling speed, and the overall cost considerations. Companies in the oil and gas industry often use a combination of both types of bits to optimize their drilling operations and achieve the best results. The continuous advancements in drill bit technology further enhance the efficiency and versatility of drilling operations, contributing to the overall growth and competitiveness of the global oil and gas drill bit market.

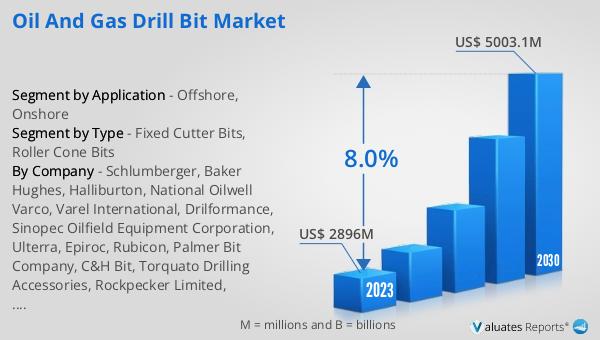

Global Oil and Gas Drill Bit Market Outlook:

The global Oil and Gas Drill Bit market was valued at US$ 2896 million in 2023 and is anticipated to reach US$ 5003.1 million by 2030, witnessing a CAGR of 8.0% during the forecast period 2024-2030. This significant growth reflects the increasing demand for energy and the continuous exploration of new oil and gas reserves. The market's expansion is driven by advancements in drilling technology, which enhance the efficiency and durability of drill bits, reducing drilling costs and improving overall productivity. The rising demand for energy in developing economies also contributes to the market's growth, as these regions invest in new exploration and extraction projects to meet their energy needs. The global oil and gas drill bit market is characterized by intense competition among key players, who continuously invest in research and development to innovate and improve their products. This competitive landscape drives the development of new and advanced drill bits, further boosting the market's growth. The market's outlook is positive, with significant opportunities for growth and development in the coming years, supported by the ongoing need for energy and the exploration of new oil and gas reserves.

| Report Metric | Details |

| Report Name | Oil and Gas Drill Bit Market |

| Accounted market size in 2023 | US$ 2896 million |

| Forecasted market size in 2030 | US$ 5003.1 million |

| CAGR | 8.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schlumberger, Baker Hughes, Halliburton, National Oilwell Varco, Varel International, Drilformance, Sinopec Oilfield Equipment Corporation, Ulterra, Epiroc, Rubicon, Palmer Bit Company, C&H Bit, Torquato Drilling Accessories, Rockpecker Limited, MICON-Drilling, Western Drilling Tools Inc, Shear bits, Volgaburmash |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |