What is Global Hot Rolled Pickled and Oiled Market?

The Global Hot Rolled Pickled and Oiled (HRPO) market refers to the industry that produces and distributes steel products that have undergone a specific treatment process. Hot rolled steel is first passed through a pickling process, which involves immersing the steel in an acid solution to remove scale and other impurities. After pickling, the steel is oiled to prevent rust and corrosion during storage and transportation. This treatment enhances the surface quality and extends the lifespan of the steel, making it more suitable for various applications. The HRPO market is essential for industries that require high-quality steel with improved mechanical properties and surface finish. It serves a wide range of sectors, including automotive, construction, and manufacturing, where durability and performance are critical. The global demand for HRPO steel is driven by its versatility and the growing need for high-strength, low-alloy materials in various industrial applications.

Sulfuric Acid Oil, Hydrochloric Acid Oil in the Global Hot Rolled Pickled and Oiled Market:

Sulfuric acid and hydrochloric acid are two primary acids used in the pickling process within the Global Hot Rolled Pickled and Oiled (HRPO) market. Sulfuric acid pickling is a traditional method that has been widely used due to its cost-effectiveness and efficiency in removing scale from hot rolled steel. The process involves immersing the steel in a sulfuric acid solution, which reacts with the iron oxide scale to form soluble iron sulfate, effectively cleaning the steel surface. This method is particularly suitable for large-scale operations due to its relatively low cost and high throughput. However, sulfuric acid pickling has some drawbacks, including the generation of hazardous waste and the need for extensive wastewater treatment to neutralize the acidic effluent. On the other hand, hydrochloric acid pickling is gaining popularity in the HRPO market due to its faster reaction rate and ability to produce a cleaner surface finish. Hydrochloric acid is more aggressive than sulfuric acid, allowing for quicker removal of scale and reducing the overall pickling time. This method also produces less sludge, making it easier to manage waste and reducing the environmental impact. Additionally, hydrochloric acid pickling can be performed at lower temperatures, which can save energy and reduce operational costs. Despite these advantages, hydrochloric acid pickling requires more stringent safety measures due to the corrosive nature of the acid and the potential for hazardous fumes. Both sulfuric acid and hydrochloric acid pickling processes play a crucial role in the HRPO market, providing essential treatments that enhance the quality and performance of hot rolled steel. The choice between the two methods depends on various factors, including cost, environmental considerations, and specific application requirements. As the HRPO market continues to evolve, advancements in pickling technologies and the development of more sustainable practices are expected to further improve the efficiency and environmental footprint of these processes.

Automobile, Mechanical, Others in the Global Hot Rolled Pickled and Oiled Market:

The Global Hot Rolled Pickled and Oiled (HRPO) market finds extensive usage in various industries, including the automobile, mechanical, and other sectors. In the automobile industry, HRPO steel is highly valued for its superior surface quality and enhanced mechanical properties. It is commonly used in the manufacturing of automotive components such as chassis, frames, and suspension parts, where strength and durability are paramount. The pickling and oiling process ensures that the steel is free from scale and rust, providing a clean surface that is ideal for further processing, such as welding and painting. This results in high-quality automotive parts that meet stringent safety and performance standards. In the mechanical industry, HRPO steel is utilized in the production of machinery and equipment that require robust and reliable materials. The improved surface finish and mechanical properties of HRPO steel make it suitable for applications such as gears, shafts, and bearings, where precision and wear resistance are critical. The pickling process removes impurities that could compromise the integrity of the steel, while the oiling process provides a protective layer that prevents corrosion during storage and transportation. This ensures that the mechanical components maintain their performance and longevity, even in demanding environments. Beyond the automobile and mechanical industries, HRPO steel is also used in various other sectors, including construction, agriculture, and manufacturing. In the construction industry, HRPO steel is employed in the fabrication of structural components such as beams, columns, and trusses, where strength and stability are essential. The clean surface of HRPO steel allows for better adhesion of coatings and paints, enhancing the durability and aesthetic appeal of the structures. In agriculture, HRPO steel is used in the production of farming equipment and machinery, where resistance to wear and corrosion is crucial for reliable operation. The versatility and high performance of HRPO steel make it a preferred choice for a wide range of applications, driving its demand across multiple industries.

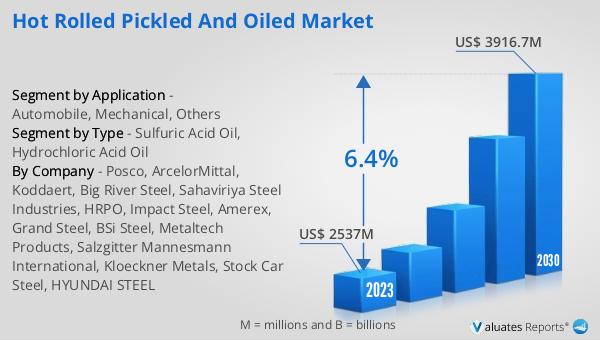

Global Hot Rolled Pickled and Oiled Market Outlook:

The global Hot Rolled Pickled and Oiled (HRPO) market was valued at US$ 2537 million in 2023 and is anticipated to reach US$ 3916.7 million by 2030, witnessing a CAGR of 6.4% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-quality steel products across various industries. The HRPO market's expansion is driven by the need for materials that offer superior surface quality, enhanced mechanical properties, and improved corrosion resistance. As industries such as automotive, construction, and manufacturing continue to evolve and require more advanced materials, the HRPO market is expected to play a crucial role in meeting these demands. The pickling and oiling process not only enhances the performance of hot rolled steel but also extends its lifespan, making it a cost-effective and reliable choice for numerous applications. The projected growth of the HRPO market underscores its importance in providing high-strength, low-alloy steel that meets the stringent requirements of modern industrial applications.

| Report Metric | Details |

| Report Name | Hot Rolled Pickled and Oiled Market |

| Accounted market size in 2023 | US$ 2537 million |

| Forecasted market size in 2030 | US$ 3916.7 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Posco, ArcelorMittal, Koddaert, Big River Steel, Sahaviriya Steel Industries, HRPO, Impact Steel, Amerex, Grand Steel, BSi Steel, Metaltech Products, Salzgitter Mannesmann International, Kloeckner Metals, Stock Car Steel, HYUNDAI STEEL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |