What is Global High Modulus and High Strength Fiberglass Market?

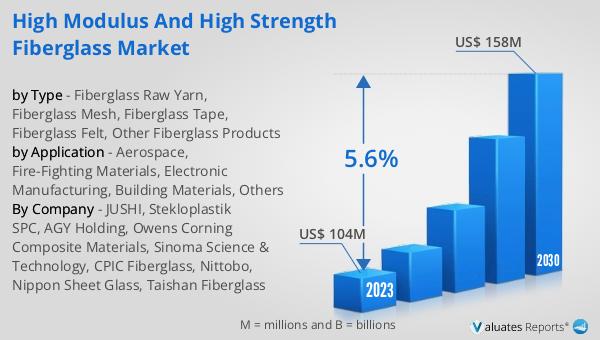

The Global High Modulus and High Strength Fiberglass Market is a fascinating sector that focuses on the production and distribution of fiberglass materials, which are known for their exceptional strength and stiffness. This market caters to a wide range of industries, offering products that are integral to various manufacturing and construction processes. High modulus and high strength fiberglass materials are distinguished by their superior mechanical properties, which include high tensile strength, durability, and resistance to corrosion, making them ideal for applications that demand robust and lightweight materials. The market's significance is underscored by its valuation at approximately US$ 104 million in 2023, with projections suggesting a growth to US$ 158 million by 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030, reflects the increasing demand for these materials across different sectors. The expansion of the market is driven by technological advancements in fiberglass production, as well as the growing recognition of the material's benefits in enhancing product performance and longevity. As industries continue to seek out materials that offer both strength and efficiency, the Global High Modulus and High Strength Fiberglass Market is poised for further growth and innovation.

Fiberglass Raw Yarn, Fiberglass Mesh, Fiberglass Tape, Fiberglass Felt, Other Fiberglass Products in the Global High Modulus and High Strength Fiberglass Market:

Diving into the specifics, the Global High Modulus and High Strength Fiberglass Market encompasses a variety of products, including Fiberglass Raw Yarn, Fiberglass Mesh, Fiberglass Tape, Fiberglass Felt, and other fiberglass-related products. Each of these products serves unique purposes and caters to different market needs. Fiberglass Raw Yarn, for instance, is a fundamental component used in the production of various fiberglass products, offering high tensile strength and resistance to chemicals. Fiberglass Mesh is widely utilized in construction and industrial applications for reinforcing purposes, providing structural stability to buildings and concrete structures. Fiberglass Tape, on the other hand, is essential for electrical insulation and repair tasks, known for its durability and resistance to high temperatures. Fiberglass Felt finds its application in filtration and insulation processes, benefiting industries that require materials with excellent filtration efficiency and thermal insulation properties. Lastly, the market also includes a range of other fiberglass products, each designed to meet specific industrial requirements. These products collectively contribute to the market's diversity and its ability to serve a broad spectrum of applications, from construction and manufacturing to aerospace and electronics. The versatility and high performance of these fiberglass materials underscore their importance in today's industrial landscape, driving the market's growth and innovation.

Aerospace, Fire-Fighting Materials, Electronic Manufacturing, Building Materials, Others in the Global High Modulus and High Strength Fiberglass Market:

The usage of the Global High Modulus and High Strength Fiberglass Market spans across several critical industries, including Aerospace, Fire-Fighting Materials, Electronic Manufacturing, Building Materials, and Others. In the Aerospace sector, these fiberglass materials are prized for their lightweight and high-strength characteristics, which contribute to the overall efficiency and performance of aerospace components. Fire-Fighting Materials also benefit from the use of high modulus and high strength fiberglass, as they require materials that can withstand extreme temperatures and provide protection against fire hazards. In the realm of Electronic Manufacturing, fiberglass is utilized for its electrical insulation properties, making it an essential component in the production of electronic devices and circuit boards. Building Materials made from high modulus and high strength fiberglass offer enhanced durability and resistance to environmental factors, making them ideal for modern construction projects that demand materials with superior performance. Additionally, the versatility of these fiberglass materials allows them to be used in a variety of other applications, further demonstrating their significance in today's market. The widespread use of high modulus and high strength fiberglass in these areas highlights its critical role in advancing technology and improving safety, efficiency, and durability across multiple industries.

Global High Modulus and High Strength Fiberglass Market Outlook:

Regarding the market outlook for the Global High Modulus and High Strength Fiberglass Market, it's noteworthy to mention that the sector, valued at US$ 104 million in 2023, is on a promising trajectory towards reaching US$ 158 million by the year 2030. This growth is expected to unfold at a compound annual growth rate (CAGR) of 5.6% throughout the forecast period spanning from 2024 to 2030. Such an optimistic forecast underscores the robust demand and expanding applications of high modulus and high strength fiberglass across various industries. The market's growth is fueled by the continuous advancements in fiberglass technology and manufacturing processes, coupled with the material's increasing recognition for its exceptional properties, including high strength, durability, and resistance to corrosion. These factors collectively contribute to the market's expansion, reflecting the growing reliance on high modulus and high strength fiberglass as a material of choice for enhancing product performance and longevity in numerous sectors. The market's positive outlook is a testament to the material's versatility and its pivotal role in driving innovation and efficiency across a broad spectrum of applications.

| Report Metric | Details |

| Report Name | High Modulus and High Strength Fiberglass Market |

| Accounted market size in 2023 | US$ 104 million |

| Forecasted market size in 2030 | US$ 158 million |

| CAGR | 5.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JUSHI, Stekloplastik SPC, AGY Holding, Owens Corning Composite Materials, Sinoma Science & Technology, CPIC Fiberglass, Nittobo, Nippon Sheet Glass, Taishan Fiberglass |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |