What is Global Heat Resistant Polymethyl Methacrylate (PMMA) Market?

The Global Heat Resistant Polymethyl Methacrylate (PMMA) Market is a specialized segment within the broader plastics industry, focusing on a type of acrylic polymer known for its exceptional heat resistance. PMMA is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. The heat-resistant variant of PMMA is engineered to withstand higher temperatures, making it suitable for applications where standard PMMA would fail. This market encompasses a wide range of industries, including automotive, medical, lighting, and architecture, among others. The demand for heat-resistant PMMA is driven by its unique properties, such as high optical clarity, UV resistance, and excellent mechanical strength. These attributes make it an ideal material for products that require durability and performance under thermal stress. The market is characterized by continuous innovation and development, with manufacturers constantly seeking to improve the material's properties and expand its applications. As industries increasingly prioritize materials that can endure harsh conditions without compromising on performance, the global heat-resistant PMMA market is poised for sustained growth.

Extrusion Grade, Injection Grade in the Global Heat Resistant Polymethyl Methacrylate (PMMA) Market:

Extrusion grade and injection grade are two primary types of heat-resistant Polymethyl Methacrylate (PMMA) used in various applications. Extrusion grade PMMA is designed for processes where the material is pushed through a die to create continuous shapes like sheets, rods, and tubes. This grade is known for its excellent clarity, UV resistance, and ease of processing, making it ideal for applications such as signage, displays, and protective barriers. The extrusion process allows for the production of large, uniform sheets that can be easily cut and shaped, providing versatility in manufacturing. On the other hand, injection grade PMMA is formulated for injection molding, a process where the material is melted and injected into a mold to create complex, detailed parts. This grade offers superior flow properties, high impact resistance, and excellent dimensional stability, making it suitable for intricate components in industries like automotive, medical devices, and consumer electronics. Injection grade PMMA is particularly valued for its ability to produce parts with tight tolerances and fine details, which are essential in high-precision applications. Both grades of heat-resistant PMMA share common benefits such as high optical clarity, resistance to UV radiation, and durability under thermal stress. However, their specific formulations and processing methods cater to different manufacturing needs and end-use applications. The choice between extrusion and injection grade PMMA depends on factors such as the desired shape, complexity, and performance requirements of the final product. As industries continue to innovate and demand materials that can withstand higher temperatures and harsh conditions, both extrusion and injection grade heat-resistant PMMA will play crucial roles in meeting these needs.

Medical, Lighting, Housewares, Optical, Automobile, Architectural, Others in the Global Heat Resistant Polymethyl Methacrylate (PMMA) Market:

Heat-resistant Polymethyl Methacrylate (PMMA) finds extensive usage across various sectors due to its unique properties. In the medical field, heat-resistant PMMA is used in the production of medical devices, surgical instruments, and dental applications. Its biocompatibility, clarity, and resistance to sterilization processes make it an ideal material for these applications. In the lighting industry, heat-resistant PMMA is used in the manufacturing of light diffusers, lenses, and covers. Its high optical clarity and UV resistance ensure that lighting products maintain their performance and appearance over time. For housewares, heat-resistant PMMA is used in kitchenware, storage containers, and decorative items. Its durability and resistance to heat make it suitable for products that are frequently exposed to high temperatures. In the optical sector, heat-resistant PMMA is used in lenses, optical fibers, and display screens. Its excellent light transmission and stability under thermal stress make it a preferred material for high-precision optical components. The automobile industry utilizes heat-resistant PMMA in the production of headlamp lenses, interior panels, and exterior trims. Its lightweight nature and resistance to UV radiation contribute to the longevity and performance of automotive components. In architectural applications, heat-resistant PMMA is used in windows, skylights, and facades. Its ability to withstand harsh weather conditions and maintain optical clarity makes it a valuable material for modern architectural designs. Other applications of heat-resistant PMMA include electronics, where it is used in protective covers and display panels, and various industrial uses where its thermal stability and mechanical strength are required. The versatility and performance of heat-resistant PMMA make it a critical material across these diverse sectors.

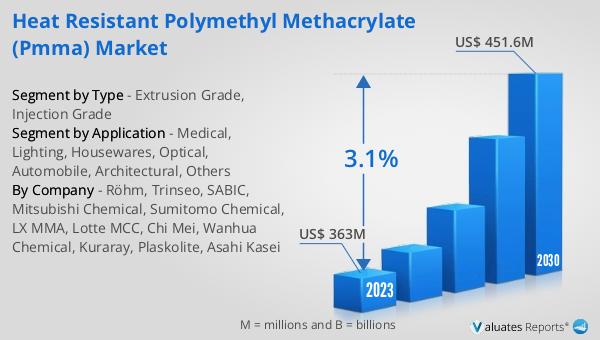

Global Heat Resistant Polymethyl Methacrylate (PMMA) Market Outlook:

The global Heat Resistant Polymethyl Methacrylate (PMMA) market was valued at US$ 363 million in 2023 and is anticipated to reach US$ 451.6 million by 2030, witnessing a CAGR of 3.1% during the forecast period from 2024 to 2030. The market is dominated by the top five manufacturers, who collectively hold a share of over 70%. Among the various product types, the injection grade segment is the largest, accounting for more than 74% of the market share. This significant market presence of injection grade PMMA highlights its widespread adoption and critical role in various high-precision applications. The steady growth of the market reflects the increasing demand for materials that can withstand higher temperatures and harsh conditions without compromising on performance. As industries continue to innovate and seek advanced materials, the global heat-resistant PMMA market is expected to maintain its upward trajectory.

| Report Metric | Details |

| Report Name | Heat Resistant Polymethyl Methacrylate (PMMA) Market |

| Accounted market size in 2023 | US$ 363 million |

| Forecasted market size in 2030 | US$ 451.6 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Röhm, Trinseo, SABIC, Mitsubishi Chemical, Sumitomo Chemical, LX MMA, Lotte MCC, Chi Mei, Wanhua Chemical, Kuraray, Plaskolite, Asahi Kasei |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |