What is Global Grinding Wheels Market?

The global grinding wheels market is a dynamic and essential segment of the manufacturing industry. Grinding wheels are tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. These wheels are made from various materials, including aluminum oxide, silicon carbide, diamond, and cubic boron nitride. They are used in a wide range of applications, from simple home-based tasks to complex industrial processes. The market for grinding wheels is driven by the increasing demand for precision tools in various industries such as automotive, aerospace, and metalworking. The growth in these industries directly impacts the demand for grinding wheels, making it a crucial component in the manufacturing process. The market is also influenced by technological advancements that lead to the development of more efficient and durable grinding wheels. These advancements help in reducing production costs and improving the quality of the final product. The global grinding wheels market is expected to continue growing, driven by the increasing need for high-quality surface finishes and the rising demand for precision engineering.

in the Global Grinding Wheels Market:

Grinding wheels come in various types, each designed to meet the specific needs of different customers based on the global grinding wheels market. The most common types include straight wheels, cylinder wheels, and cup wheels. Straight wheels are the most basic and are used for surface grinding operations. They are ideal for sharpening tools and other simple grinding tasks. Cylinder wheels, on the other hand, are used for larger surface areas and are commonly found in industrial settings. They are designed to handle heavy-duty grinding tasks and are often used in the manufacturing of large machinery parts. Cup wheels are another type, primarily used for grinding on flat surfaces. They are commonly used in the construction industry for tasks such as smoothing concrete surfaces. Another important type is the diamond wheel, which is known for its hardness and durability. Diamond wheels are used for precision grinding tasks, especially in the aerospace and automotive industries. They are ideal for grinding hard materials such as ceramics and glass. Silicon carbide wheels are another type, known for their ability to grind non-ferrous metals. They are commonly used in the metalworking industry for tasks such as deburring and finishing. Cubic boron nitride (CBN) wheels are also popular, especially in the automotive industry. They are known for their ability to maintain sharpness and are used for grinding hard ferrous materials. Resinoid bond wheels are another type, known for their flexibility and ability to handle high-speed grinding tasks. They are commonly used in the manufacturing of cutting tools and other precision instruments. Vitrified bond wheels are also widely used, known for their strength and durability. They are ideal for heavy-duty grinding tasks and are commonly used in the steel industry. Each type of grinding wheel has its unique properties and is designed to meet the specific needs of different industries. The choice of grinding wheel depends on various factors, including the material to be ground, the desired surface finish, and the specific requirements of the task at hand. The global grinding wheels market offers a wide range of options to meet the diverse needs of different customers, making it an essential component of the manufacturing industry.

Transport Industry, Bearing & Machinery, Construction, Steel Industry, Oil & Gas, Others in the Global Grinding Wheels Market:

The global grinding wheels market finds extensive usage across various industries, including the transport industry, bearing and machinery, construction, steel industry, oil and gas, and others. In the transport industry, grinding wheels are used for manufacturing and maintaining various components such as engine parts, brake systems, and transmission components. They help in achieving high precision and smooth surface finishes, which are crucial for the efficient functioning of these components. In the bearing and machinery industry, grinding wheels are used for manufacturing and maintaining various types of bearings and machinery parts. They help in achieving high precision and smooth surface finishes, which are crucial for the efficient functioning of these components. In the construction industry, grinding wheels are used for tasks such as cutting, grinding, and polishing concrete, stones, and other construction materials. They help in achieving smooth and precise finishes, which are crucial for the quality and durability of the construction work. In the steel industry, grinding wheels are used for tasks such as cutting, grinding, and polishing steel and other metals. They help in achieving high precision and smooth surface finishes, which are crucial for the quality and durability of the steel products. In the oil and gas industry, grinding wheels are used for manufacturing and maintaining various components such as drill bits, pipes, and valves. They help in achieving high precision and smooth surface finishes, which are crucial for the efficient functioning of these components. Other industries that use grinding wheels include aerospace, electronics, and medical devices. In the aerospace industry, grinding wheels are used for manufacturing and maintaining various components such as turbine blades, engine parts, and landing gear. They help in achieving high precision and smooth surface finishes, which are crucial for the efficient functioning of these components. In the electronics industry, grinding wheels are used for manufacturing and maintaining various components such as semiconductor wafers, connectors, and circuit boards. They help in achieving high precision and smooth surface finishes, which are crucial for the efficient functioning of these components. In the medical devices industry, grinding wheels are used for manufacturing and maintaining various components such as surgical instruments, implants, and diagnostic equipment. They help in achieving high precision and smooth surface finishes, which are crucial for the quality and safety of the medical devices. The global grinding wheels market plays a crucial role in the manufacturing and maintenance of various components across different industries, making it an essential component of the global economy.

Global Grinding Wheels Market Outlook:

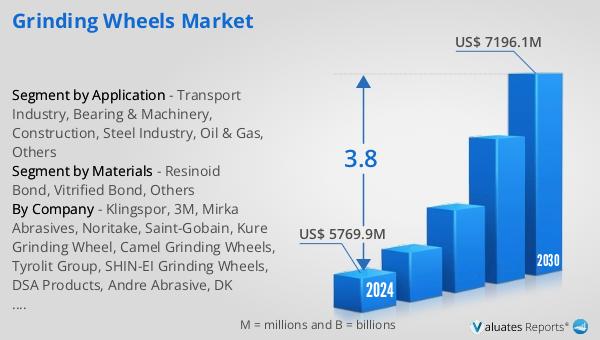

The global grinding wheels market is anticipated to grow significantly, with projections indicating it will reach approximately US$ 7196.1 million by 2030, up from an estimated US$ 5769.9 million in 2024, reflecting a compound annual growth rate (CAGR) of 3.8% between 2024 and 2030. Saint-Gobain stands out as the largest manufacturer in this market, holding a substantial 15% market share. When it comes to product materials, resinoid bond grinding wheels dominate the market with a 60% share, followed by vitrified bond grinding wheels at 35%. In terms of application, the transport industry is the leading sector, accounting for 38% of the market share, followed closely by the bearings and machinery sector. This growth is driven by the increasing demand for precision tools and high-quality surface finishes in various industries. The advancements in technology and the development of more efficient and durable grinding wheels also contribute to the market's expansion. The global grinding wheels market is expected to continue its upward trajectory, driven by the rising demand for precision engineering and high-quality surface finishes across different industries.

| Report Metric | Details |

| Report Name | Grinding Wheels Market |

| Accounted market size in 2024 | an estimated US$ 5769.9 million |

| Forecasted market size in 2030 | US$ 7196.1 million |

| CAGR | 3.8% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Materials |

|

| Segment by Application |

|

| By Region |

|

| By Company | Klingspor, 3M, Mirka Abrasives, Noritake, Saint-Gobain, Kure Grinding Wheel, Camel Grinding Wheels, Tyrolit Group, SHIN-EI Grinding Wheels, DSA Products, Andre Abrasive, DK Holdings, ELKA-Elastic, Keihin Kogyosho Co., Ltd, Northern Grinding Wheels, Hebei Sanfeng Abrasives, Hindustan Abrasives, GRANIT Grinding Wheel Ltd, ATLANTIC GmbH, AWUKO Abrasives, Abrasivos Manhattan SA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |