What is Global Electrostatic Dissipative Coating (ESD Coating) Market?

The global Electrostatic Dissipative Coating (ESD Coating) market is a specialized segment within the broader coatings industry, focusing on materials that prevent the buildup of static electricity. These coatings are essential in environments where static discharge can cause significant damage, such as in electronics manufacturing, data processing centers, and military applications. ESD coatings work by dissipating static charges safely to the ground, thereby protecting sensitive electronic components and reducing the risk of fire or explosion in volatile environments. The market for ESD coatings is driven by the increasing demand for electronic devices, the need for safer work environments, and stringent regulations regarding static discharge. These coatings are available in various forms, including water-based and solvent-based, each with its own set of advantages and applications. The market is highly competitive, with numerous players offering a range of products to meet the diverse needs of different industries. As technology continues to advance, the demand for effective ESD solutions is expected to grow, making this an exciting and dynamic market to watch.

Water-Based ESD Coating, Solvent-Based ESD Coating in the Global Electrostatic Dissipative Coating (ESD Coating) Market:

Water-based ESD coatings are a popular choice in the global Electrostatic Dissipative Coating market due to their environmental benefits and ease of application. These coatings use water as a solvent, making them less harmful to the environment and safer for workers to handle. They are particularly effective in applications where low toxicity and minimal environmental impact are crucial. Water-based ESD coatings are commonly used in electronics manufacturing, where they provide excellent protection against static discharge without compromising the performance of sensitive components. They are also favored in data processing centers, where maintaining a clean and safe environment is essential. On the other hand, solvent-based ESD coatings use organic solvents, which can offer superior performance in terms of durability and resistance to wear and tear. These coatings are often used in more demanding environments, such as military and aerospace applications, where the highest levels of protection are required. Solvent-based ESD coatings are known for their excellent adhesion properties and ability to withstand harsh conditions, making them ideal for use in extreme environments. However, they can be more challenging to apply and may require specialized equipment and safety measures due to the presence of volatile organic compounds (VOCs). Despite these challenges, solvent-based ESD coatings remain a popular choice for applications where performance and durability are paramount. Both water-based and solvent-based ESD coatings play a crucial role in the global market, offering a range of solutions to meet the diverse needs of different industries. As regulations around environmental impact and worker safety continue to tighten, the demand for water-based ESD coatings is expected to grow, while solvent-based coatings will continue to be essential in applications where their unique properties are required.

Electronics, Data Processing, Military & Aerospace, Other in the Global Electrostatic Dissipative Coating (ESD Coating) Market:

The usage of Global Electrostatic Dissipative Coating (ESD Coating) in various sectors such as electronics, data processing, military, aerospace, and others is extensive and multifaceted. In the electronics industry, ESD coatings are crucial for protecting sensitive components from static discharge, which can cause significant damage and lead to costly repairs or replacements. These coatings are applied to circuit boards, connectors, and other electronic parts to ensure they remain functional and reliable. In data processing centers, ESD coatings help maintain a safe and efficient environment by preventing static buildup that can disrupt operations and damage equipment. These coatings are used on floors, walls, and workstations to create a controlled environment where static discharge is minimized. In the military and aerospace sectors, ESD coatings are essential for protecting critical equipment and systems from static discharge, which can compromise their performance and safety. These coatings are used on a wide range of components, from communication devices to navigation systems, ensuring they remain operational in extreme conditions. Other industries that benefit from ESD coatings include healthcare, automotive, and manufacturing, where the protection of sensitive equipment and components is vital. In healthcare, ESD coatings are used to protect medical devices and equipment from static discharge, ensuring they function correctly and safely. In the automotive industry, these coatings are applied to electronic components and systems to prevent static discharge that can cause malfunctions or damage. In manufacturing, ESD coatings are used to protect machinery and equipment from static buildup, ensuring smooth and efficient operations. Overall, the usage of ESD coatings in these various sectors highlights their importance in maintaining the safety, reliability, and performance of critical equipment and systems.

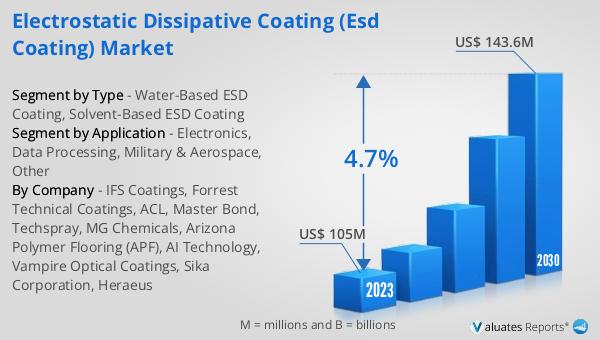

Global Electrostatic Dissipative Coating (ESD Coating) Market Outlook:

The global Electrostatic Dissipative Coating (ESD Coating) market was valued at US$ 105 million in 2023 and is anticipated to reach US$ 143.6 million by 2030, witnessing a CAGR of 4.7% during the forecast period 2024-2030. This growth is driven by the increasing demand for electronic devices, the need for safer work environments, and stringent regulations regarding static discharge. The market is highly competitive, with numerous players offering a range of products to meet the diverse needs of different industries. As technology continues to advance, the demand for effective ESD solutions is expected to grow, making this an exciting and dynamic market to watch. The market's growth is also supported by the increasing adoption of water-based ESD coatings, which offer environmental benefits and ease of application. These coatings are particularly effective in applications where low toxicity and minimal environmental impact are crucial. On the other hand, solvent-based ESD coatings continue to be essential in more demanding environments, such as military and aerospace applications, where the highest levels of protection are required. Overall, the global ESD coating market is poised for significant growth, driven by the increasing demand for electronic devices, the need for safer work environments, and stringent regulations regarding static discharge.

| Report Metric | Details |

| Report Name | Electrostatic Dissipative Coating (ESD Coating) Market |

| Accounted market size in 2023 | US$ 105 million |

| Forecasted market size in 2030 | US$ 143.6 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IFS Coatings, Forrest Technical Coatings, ACL, Master Bond, Techspray, MG Chemicals, Arizona Polymer Flooring (APF), AI Technology, Vampire Optical Coatings, Sika Corporation, Heraeus |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |