What is Global Duck Cut Up Machine Market?

The Global Duck Cut Up Machine Market refers to the industry that manufactures and sells machines specifically designed to cut up ducks into various parts. These machines are used in poultry processing plants to efficiently and hygienically separate duck meat into portions such as breasts, thighs, wings, and drumsticks. The market encompasses a range of machines from manual to fully automated systems, catering to different scales of operations from small businesses to large industrial plants. The demand for these machines is driven by the increasing consumption of duck meat worldwide, as well as the need for more efficient and sanitary processing methods. The market includes various players, from small manufacturers to large corporations, each offering different levels of technology and customization to meet the specific needs of their clients.

Mannual, Semi-Automatic, Automatic in the Global Duck Cut Up Machine Market:

In the Global Duck Cut Up Machine Market, machines can be categorized into three main types: manual, semi-automatic, and automatic. Manual duck cut up machines require human intervention for operation. These machines are typically used in smaller operations where the volume of ducks processed is relatively low. They are cost-effective and easy to maintain but require significant labor input. Semi-automatic machines, on the other hand, combine manual labor with automated processes. These machines usually have automated cutting mechanisms but still require human operators to load the ducks and oversee the process. Semi-automatic machines are suitable for medium-sized operations where there is a need to balance efficiency with cost. They offer a good compromise between manual and fully automated systems, providing increased productivity without the high costs associated with full automation. Automatic duck cut up machines are the most advanced and are designed for large-scale industrial operations. These machines can process a high volume of ducks with minimal human intervention. They are equipped with sophisticated sensors and cutting mechanisms that ensure precise and consistent cuts. Automatic machines are highly efficient and can significantly reduce labor costs, but they require a substantial initial investment and regular maintenance. The choice between manual, semi-automatic, and automatic machines depends on various factors, including the scale of operation, budget, and specific processing requirements. Each type of machine has its own advantages and disadvantages, and businesses need to carefully consider their needs before making a decision.

Commercial, Industrial in the Global Duck Cut Up Machine Market:

The usage of Global Duck Cut Up Machines varies significantly between commercial and industrial settings. In commercial settings, such as small butcher shops or local markets, manual and semi-automatic machines are more commonly used. These machines are suitable for smaller volumes of ducks and provide the flexibility needed for custom cuts and special orders. Commercial users often prioritize cost-effectiveness and ease of use, making manual and semi-automatic machines an ideal choice. These machines allow for a hands-on approach, which can be important for maintaining quality and meeting specific customer demands. In industrial settings, such as large poultry processing plants, automatic duck cut up machines are the preferred choice. These machines are capable of processing large volumes of ducks quickly and efficiently, which is essential for meeting the high demand in industrial operations. Automatic machines ensure consistent cuts and can operate continuously, reducing downtime and increasing overall productivity. Industrial users often prioritize efficiency and throughput, making the investment in automatic machines worthwhile. Additionally, industrial settings require strict adherence to hygiene and safety standards, and automatic machines are designed to meet these requirements with features such as easy-to-clean surfaces and advanced safety mechanisms. The choice of machine in both commercial and industrial settings ultimately depends on the specific needs and priorities of the business.

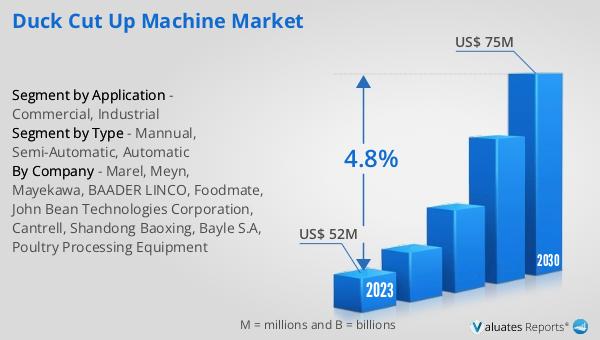

Global Duck Cut Up Machine Market Outlook:

The global Duck Cut Up Machine market was valued at US$ 52 million in 2023 and is anticipated to reach US$ 75 million by 2030, witnessing a CAGR of 4.8% during the forecast period 2024-2030. This market growth reflects the increasing demand for efficient and hygienic duck processing solutions worldwide. The rising consumption of duck meat, driven by its popularity in various cuisines and its nutritional benefits, is a key factor contributing to this market expansion. Additionally, advancements in technology and the development of more sophisticated and efficient machines are expected to further drive market growth. The market includes a diverse range of players, from small manufacturers to large corporations, each offering different levels of technology and customization to meet the specific needs of their clients. The projected growth in the market indicates a positive outlook for the industry, with opportunities for innovation and expansion in both existing and emerging markets.

| Report Metric | Details |

| Report Name | Duck Cut Up Machine Market |

| Accounted market size in 2023 | US$ 52 million |

| Forecasted market size in 2030 | US$ 75 million |

| CAGR | 4.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Marel, Meyn, Mayekawa, BAADER LINCO, Foodmate, John Bean Technologies Corporation, Cantrell, Shandong Baoxing, Bayle S.A, Poultry Processing Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |