What is Global Anode Binders for Lithium Batteries Market?

The global Anode Binders for Lithium Batteries market is a specialized segment within the broader battery materials industry. Anode binders are crucial components in lithium-ion batteries, serving to hold the active material particles together and adhere them to the current collector. This ensures the structural integrity and performance of the battery during charge and discharge cycles. The market for anode binders is driven by the increasing demand for lithium-ion batteries, which are widely used in various applications such as consumer electronics, electric vehicles, and industrial energy storage systems. The growth in these sectors, particularly the rapid adoption of electric vehicles, has significantly boosted the demand for high-performance anode binders. These binders must possess excellent mechanical properties, chemical stability, and compatibility with other battery components to enhance the overall efficiency and lifespan of lithium-ion batteries. As the technology evolves, the market continues to see innovations and improvements in binder materials, aiming to meet the stringent requirements of next-generation batteries.

Polyvinylidene Fluoride (PVDF) Based Binders, Styrene-Butadiene Rubber (SBR) Based Binders, Other in the Global Anode Binders for Lithium Batteries Market:

Polyvinylidene Fluoride (PVDF) based binders are among the most commonly used anode binders in lithium-ion batteries. PVDF is favored for its excellent chemical resistance, thermal stability, and strong adhesion properties. These characteristics make it an ideal choice for ensuring the durability and performance of lithium-ion batteries, especially in high-demand applications such as electric vehicles and high-capacity energy storage systems. PVDF binders help in maintaining the structural integrity of the anode during repeated charge and discharge cycles, thereby enhancing the battery's lifespan and efficiency. On the other hand, Styrene-Butadiene Rubber (SBR) based binders are also widely used, particularly in applications where flexibility and cost-effectiveness are crucial. SBR binders offer good mechanical properties and are often used in combination with other materials to improve the overall performance of the anode. They are particularly popular in consumer electronics and other applications where the battery's mechanical flexibility is important. Additionally, there are other types of binders used in the market, including carboxymethyl cellulose (CMC) and other water-based binders. These alternatives are often chosen for their environmental benefits and ease of processing. CMC, for instance, is a water-soluble binder that provides good adhesion and mechanical properties while being more environmentally friendly compared to solvent-based binders like PVDF. The choice of binder material often depends on the specific requirements of the battery application, including factors such as cost, performance, and environmental impact. As the demand for lithium-ion batteries continues to grow, the market for anode binders is expected to see further diversification and innovation, with new materials and formulations being developed to meet the evolving needs of the industry.

Consumer Electronics, Automobile, Industrial, Other in the Global Anode Binders for Lithium Batteries Market:

The usage of anode binders in lithium-ion batteries spans across various sectors, including consumer electronics, automobiles, industrial applications, and others. In the consumer electronics sector, lithium-ion batteries are widely used in devices such as smartphones, laptops, tablets, and wearable technology. The demand for high-performance, long-lasting batteries in these devices drives the need for advanced anode binders that can enhance battery efficiency and lifespan. PVDF and SBR binders are commonly used in this sector due to their excellent adhesion properties and mechanical flexibility. In the automobile sector, the rapid adoption of electric vehicles (EVs) has significantly increased the demand for high-capacity lithium-ion batteries. Anode binders play a crucial role in ensuring the structural integrity and performance of these batteries, which are subjected to rigorous charge and discharge cycles. PVDF binders are particularly favored in this sector for their thermal stability and chemical resistance, which are essential for the demanding conditions of automotive applications. In industrial applications, lithium-ion batteries are used for energy storage systems, power tools, and backup power supplies. The performance and reliability of these batteries are critical, and anode binders such as PVDF and CMC are used to enhance their durability and efficiency. The industrial sector often requires batteries with high energy density and long cycle life, making the choice of binder material crucial for meeting these demands. Additionally, other sectors such as aerospace, medical devices, and renewable energy systems also utilize lithium-ion batteries, further driving the demand for high-performance anode binders. The continuous advancements in binder materials and formulations are essential to meet the diverse requirements of these applications, ensuring the efficient and reliable performance of lithium-ion batteries across various sectors.

Global Anode Binders for Lithium Batteries Market Outlook:

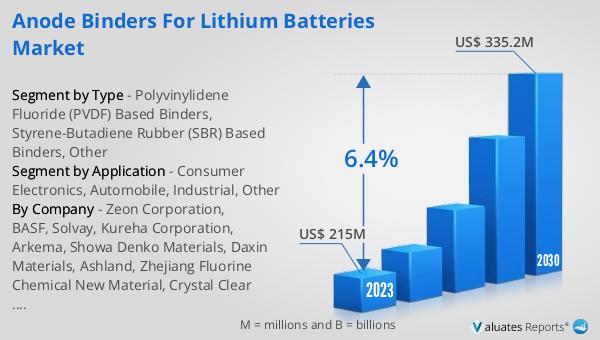

The global Anode Binders for Lithium Batteries market was valued at US$ 215 million in 2023 and is anticipated to reach US$ 335.2 million by 2030, witnessing a CAGR of 6.4% during the forecast period 2024-2030. In 2022, China’s new energy vehicle sales reached 6.8 million units, and the global share increased to 63.6%. In Q4 2022, the sales penetration rate of China’s new energy vehicles reached 27%, while the global average penetration rate was only 15%. Europe’s penetration was 19%, and North America’s penetration rate was only 6%. According to the Ministry of Industry and Information Technology, China’s lithium-ion battery production reached 750 GWh in 2022, up more than 130 percent year on year.

| Report Metric | Details |

| Report Name | Anode Binders for Lithium Batteries Market |

| Accounted market size in 2023 | US$ 215 million |

| Forecasted market size in 2030 | US$ 335.2 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zeon Corporation, BASF, Solvay, Kureha Corporation, Arkema, Showa Denko Materials, Daxin Materials, Ashland, Zhejiang Fluorine Chemical New Material, Crystal Clear Electronic Material, Sichuan Indigo Technology, Shandong Huaxia Shenzhou New Materials, Fujian Blue Ocean & Black Stone |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |