What is Global 3D Printing Technology in Pharmaceutical Market?

Global 3D Printing Technology in the Pharmaceutical Market is a revolutionary advancement that is transforming the way medications are developed, manufactured, and delivered. This technology involves the use of 3D printers to create pharmaceutical products with precise control over their shape, size, and dosage. By utilizing computer-aided design (CAD) software, pharmaceutical companies can design complex drug formulations and produce them layer by layer using various materials. This method allows for the creation of customized medications tailored to individual patient needs, improving treatment efficacy and reducing side effects. Additionally, 3D printing technology enables the production of complex drug delivery systems, such as multi-layered tablets and implants, which can release drugs at controlled rates over extended periods. The ability to produce small batches of drugs on-demand also reduces waste and lowers production costs. Overall, the integration of 3D printing technology in the pharmaceutical market holds great promise for enhancing patient care and streamlining drug manufacturing processes.

Material Extrusion, Binder Jetting, Powder Bed Fusion, VAT Photopolymerization in the Global 3D Printing Technology in Pharmaceutical Market:

Material Extrusion, Binder Jetting, Powder Bed Fusion, and VAT Photopolymerization are four key 3D printing technologies utilized in the pharmaceutical market, each offering unique advantages for drug development and production. Material Extrusion involves the deposition of a continuous filament of material through a heated nozzle, which is then precisely layered to form the desired shape. This method is particularly useful for creating personalized dosage forms and complex drug delivery systems. Binder Jetting, on the other hand, uses a liquid binding agent to selectively join powder particles, layer by layer, to build a solid object. This technique is ideal for producing porous structures and multi-material constructs, making it suitable for creating intricate drug formulations and scaffolds for tissue engineering. Powder Bed Fusion employs a high-energy source, such as a laser or electron beam, to selectively fuse powder particles together, layer by layer. This method allows for the production of highly detailed and mechanically robust drug delivery devices, such as implants and micro-needles. VAT Photopolymerization, also known as stereolithography, uses a light source to selectively cure a liquid photopolymer resin, layer by layer, to form a solid object. This technology is highly precise and can produce complex geometries with fine details, making it ideal for creating intricate drug delivery systems and personalized medicine. Each of these 3D printing technologies offers unique capabilities that can be leveraged to enhance drug development, improve patient outcomes, and streamline manufacturing processes in the pharmaceutical industry.

Mass Production, Personalized Medicine in the Global 3D Printing Technology in Pharmaceutical Market:

The usage of Global 3D Printing Technology in the Pharmaceutical Market extends to various areas, including mass production and personalized medicine, each offering distinct benefits and applications. In mass production, 3D printing technology enables the efficient and cost-effective manufacturing of large quantities of pharmaceutical products. By automating the production process and reducing the need for manual labor, 3D printing can significantly lower production costs and increase output. This is particularly beneficial for producing generic drugs and over-the-counter medications, where high volumes are required to meet market demand. Additionally, 3D printing allows for the rapid prototyping and testing of new drug formulations, accelerating the development process and bringing new medications to market faster. On the other hand, personalized medicine is one of the most promising applications of 3D printing technology in the pharmaceutical market. By leveraging the precision and flexibility of 3D printing, pharmaceutical companies can create customized medications tailored to individual patient needs. This includes adjusting the dosage, shape, and release profile of drugs to optimize therapeutic outcomes and minimize side effects. For example, 3D printing can be used to produce multi-layered tablets that release different drugs at specific times, providing a more effective treatment regimen for patients with complex medical conditions. Furthermore, 3D printing enables the creation of patient-specific implants and drug delivery devices, such as micro-needles and transdermal patches, which can improve the efficacy and convenience of treatments. Overall, the integration of 3D printing technology in mass production and personalized medicine holds great potential for enhancing patient care, improving treatment outcomes, and revolutionizing the pharmaceutical industry.

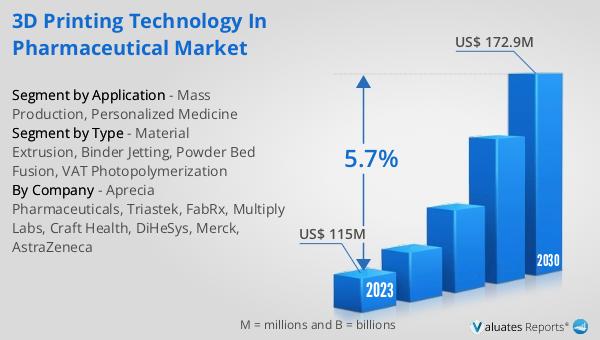

Global 3D Printing Technology in Pharmaceutical Market Outlook:

The global 3D Printing Technology in the Pharmaceutical market was valued at US$ 115 million in 2023 and is anticipated to reach US$ 172.9 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. The global pharmaceutical market is valued at 1475 billion USD in 2022, growing at a CAGR of 5% over the next six years. In comparison, the chemical drug market is estimated to increase from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth reflects the increasing adoption of advanced technologies, such as 3D printing, to enhance drug development and manufacturing processes. The ability to produce customized medications and complex drug delivery systems using 3D printing technology is driving innovation and improving patient outcomes. As the pharmaceutical industry continues to evolve, the integration of 3D printing technology is expected to play a crucial role in shaping the future of drug development and production.

| Report Metric | Details |

| Report Name | 3D Printing Technology in Pharmaceutical Market |

| Accounted market size in 2023 | US$ 115 million |

| Forecasted market size in 2030 | US$ 172.9 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Aprecia Pharmaceuticals, Triastek, FabRx, Multiply Labs, Craft Health, DiHeSys, Merck, AstraZeneca |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |