What is CVD Coated Turning Insert - Global Market?

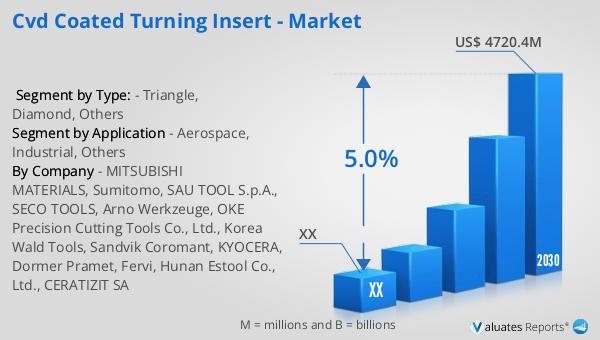

The CVD Coated Turning Insert - Global Market is an intriguing sector that revolves around the use of specialized inserts for cutting and shaping materials in manufacturing processes. These inserts are treated with a Chemical Vapor Deposition (CVD) coating, a technique that enhances their durability, efficiency, and performance. The global market for these CVD coated inserts was valued at a significant figure in 2023, indicating their widespread adoption and utility across various industries. This market is projected to grow steadily, reaching a higher valuation by 2030, thanks to a compound annual growth rate (CAGR) of 5.0%. This growth is driven by the increasing demand for high-quality, durable cutting tools that can withstand the rigors of modern manufacturing processes. The North American segment of this market, in particular, has shown promising growth figures, starting from 2023 and expected to continue its upward trajectory through 2030. This growth is a testament to the region's robust manufacturing sector and its ongoing need for advanced tools that can improve efficiency and productivity. The CVD Coated Turning Insert market's expansion is a clear indicator of the manufacturing industry's evolution, where precision and durability are paramount.

Triangle, Diamond, Others in the CVD Coated Turning Insert - Global Market:

In the realm of the CVD Coated Turning Insert - Global Market, the variety of shapes like Triangle, Diamond, and Others play a pivotal role in determining their application and effectiveness. Each shape is designed to offer specific advantages in cutting, shaping, and finishing tasks across a wide range of materials. Triangle inserts are known for their strong cutting edges, making them suitable for heavy cutting loads. Diamond-shaped inserts, on the other hand, are preferred for their sharp angles and superior precision, especially in finishing tasks where detail and accuracy are crucial. The "Others" category encompasses a variety of shapes, each tailored to meet unique manufacturing needs, from complex contours to specialized finishes. The global market for these inserts is vast and varied, catering to a multitude of industries from aerospace to automotive, and beyond. The demand for these differently shaped inserts is driven by their ability to improve manufacturing efficiency, reduce downtime, and extend the life of cutting equipment. As industries continue to evolve and seek out more efficient and cost-effective manufacturing solutions, the market for these specialized CVD coated turning inserts is expected to grow, reflecting the diverse and changing needs of global manufacturing.

Aerospace, Industrial, Others in the CVD Coated Turning Insert - Global Market:

The usage of CVD Coated Turning Insert in the global market spans across several critical sectors such as Aerospace, Industrial, and Others, each with its unique demands and applications. In the aerospace sector, these inserts are prized for their precision and durability, essential for manufacturing components that must withstand extreme conditions. The industrial sector, encompassing a broad range of manufacturing activities, relies on these inserts for their versatility and efficiency in cutting and shaping a variety of materials, from metals to composites. Other sectors, including but not limited to automotive, energy, and electronics, also benefit from the advanced properties of CVD coated inserts, such as their resistance to wear and ability to maintain sharpness over prolonged periods. This widespread usage underscores the importance of these inserts in modern manufacturing, where they contribute significantly to productivity and quality. The global market for CVD Coated Turning Inserts is thus a reflection of the critical role these tools play across diverse industries, driving demand and innovation in material processing technologies. As manufacturing processes become more sophisticated, the reliance on high-performance tools like CVD coated turning inserts is expected to increase, further propelling the market's growth.

CVD Coated Turning Insert - Global Market Outlook:

The market outlook for CVD Coated Turning Inserts presents a promising future, with the global valuation estimated at US$ 3354.7 million in 2023 and anticipated to reach US$ 4720.4 million by 2030. This growth trajectory, marked by a CAGR of 5.0% during the forecast period from 2024 to 2030, underscores the increasing reliance on these advanced manufacturing tools across various industries. The North American segment, in particular, has shown significant promise, starting from a strong valuation in 2023 and projected to continue its growth momentum through 2030. This region's performance is indicative of the robust manufacturing sector's demand for high-quality, durable cutting tools that enhance productivity and efficiency. The global and regional market expansions reflect the broader trends in manufacturing towards adopting more advanced, reliable, and efficient tools to meet the growing complexities and demands of modern production lines. As industries continue to evolve, the demand for CVD Coated Turning Inserts is expected to rise, driven by their proven benefits in improving manufacturing outcomes.

| Report Metric | Details |

| Report Name | CVD Coated Turning Insert - Market |

| Forecasted market size in 2030 | US$ 4720.4 million |

| CAGR | 5.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | MITSUBISHI MATERIALS, Sumitomo, SAU TOOL S.p.A., SECO TOOLS, Arno Werkzeuge, OKE Precision Cutting Tools Co., Ltd., Korea Wald Tools, Sandvik Coromant, KYOCERA, Dormer Pramet, Fervi, Hunan Estool Co., Ltd., CERATIZIT SA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |