What is Automatic Filling System - Global Market?

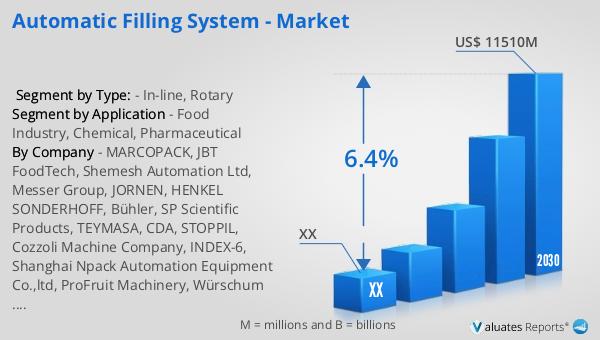

The Automatic Filling System global market is a dynamic and essential component of modern manufacturing and packaging industries, ensuring efficiency and precision in the filling of various products. At its core, an automatic filling system is designed to dispense the right amount of product into containers, ranging from liquids and powders to granular materials and pastes, without manual intervention. This technology is pivotal in maintaining consistency, speed, and accuracy in production lines, thereby significantly reducing waste and increasing productivity. The market for these systems is driven by the growing demand for packaged goods across the globe, advancements in automation technology, and the increasing emphasis on operational efficiency and compliance with regulatory standards. As of 2023, the market was valued at approximately US$ 7450 million and is anticipated to expand to US$ 11510 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.4% during the forecast period from 2024 to 2030. This growth trajectory underscores the importance and adoption of automatic filling systems in various sectors, including food and beverages, pharmaceuticals, cosmetics, and chemicals, among others. The North American region, in particular, has shown significant investment in these systems, indicating a robust market presence and potential for future growth.

In-line, Rotary in the Automatic Filling System - Global Market:

Diving into the specifics, the Automatic Filling System global market is segmented into in-line and rotary systems, each catering to different production needs and scales. In-line filling systems are designed for operations where space is at a premium and flexibility is required. These systems are ideal for handling a wide range of viscosities and container sizes, making them versatile for small to medium production volumes. On the other hand, rotary filling systems are suited for high-volume production environments. They are characterized by their circular configuration, where containers are filled as they move in a rotary fashion. This design allows for continuous operation and higher throughput, making rotary fillers the go-to for industries with large-scale production demands. Both types of systems are equipped with advanced technologies, including programmable logic controllers (PLC) and touch screen interfaces, for precise control and easy operation. The choice between in-line and rotary systems depends on several factors, including production volume, container type, product characteristics, and available floor space. As the global market for Automatic Filling Systems continues to grow, the advancements in these technologies are expected to evolve, offering even greater efficiency and adaptability to meet the changing needs of industries worldwide.

Food Industry, Chemical, Pharmaceutical in the Automatic Filling System - Global Market:

In the realm of the Automatic Filling System global market, its application across the food industry, chemical sector, and pharmaceutical field showcases its versatility and critical role in modern manufacturing. In the food industry, automatic filling systems are indispensable for ensuring the accurate, hygienic, and efficient packaging of a wide array of products, from beverages and sauces to dairy and grain-based foods. These systems help in maintaining the integrity and freshness of food products, adhering to stringent health and safety standards. In the chemical industry, the precision and robustness of automatic filling systems are crucial for handling substances that may be volatile, corrosive, or otherwise hazardous. These systems are designed to operate in challenging environments, ensuring that chemicals are packaged safely and in compliance with regulatory requirements. Meanwhile, in the pharmaceutical sector, the demand for automatic filling systems is driven by the need for utmost accuracy, sterility, and consistency in the packaging of medicines and other health-related products. These systems are tailored to meet the industry's rigorous standards, providing solutions that support the safe distribution and use of pharmaceuticals. Across these sectors, the adoption of automatic filling systems is propelled by the benefits they offer, including reduced labor costs, minimized product waste, and enhanced production efficiency. As industries continue to evolve and consumer demands shift, the role of automatic filling systems in ensuring product quality and operational excellence becomes increasingly significant.

Automatic Filling System - Global Market Outlook:

The market outlook for the Automatic Filling System global market presents a promising future, with the industry's valuation set to rise from US$ 7450 million in 2023 to an estimated US$ 11510 million by 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 6.4% during the forecast period from 2024 to 2030, highlights the expanding role and adoption of automatic filling systems across various sectors. The North American region, in particular, has demonstrated a strong market presence, with significant investments and technological advancements driving the demand for these systems. The projected growth is indicative of the increasing reliance on automation and efficiency in production processes, as businesses strive to meet the rising consumer demand for packaged goods and adhere to stringent quality and safety standards. This outlook underscores the importance of automatic filling systems in enhancing productivity, reducing operational costs, and ensuring the consistency and quality of products. As the market continues to evolve, the adoption of these systems is expected to grow, reflecting their critical role in the future of manufacturing and packaging industries.

| Report Metric | Details |

| Report Name | Automatic Filling System - Market |

| Forecasted market size in 2030 | US$ 11510 million |

| CAGR | 6.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | MARCOPACK, JBT FoodTech, Shemesh Automation Ltd, Messer Group, JORNEN, HENKEL SONDERHOFF, Bühler, SP Scientific Products, TEYMASA, CDA, STOPPIL, Cozzoli Machine Company, INDEX-6, Shanghai Npack Automation Equipment Co.,ltd, ProFruit Machinery, Würschum GmbH, OCME SOLUTIONS, Filamatic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |