What is Anti-static Foam Packaging - Global Market?

In the realm of packaging, anti-static foam packaging stands out as a specialized solution designed to protect sensitive electronic components from static electricity during shipping and handling. This type of packaging is crucial in the global market because static electricity can cause irreparable damage to electronic items, leading to significant financial losses and operational disruptions. Anti-static foam packaging is engineered to dissipate static charges safely away from the products it encases, thereby safeguarding them from electrostatic discharge (ESD). This packaging solution is widely utilized across various sectors, including electronics, automotive, and industrial goods, due to its lightweight nature, cushioning properties, and versatility in packaging design. As industries continue to advance technologically, the demand for anti-static foam packaging is expected to rise, reflecting its essential role in protecting high-value and sensitive products during transit.

High-Density Polyethylene, Middle-Density Polyethylene, Low-Density Polyethylene, Linear Low-Density Polyethylene in the Anti-static Foam Packaging - Global Market:

Diving deeper into the anti-static foam packaging market, we find it segmented by the types of polyethylene used, namely High-Density Polyethylene (HDPE), Middle-Density Polyethylene (MDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE). Each type offers unique properties suited to different packaging needs. HDPE is known for its strength and rigidity, making it ideal for protecting heavy or bulky items. MDPE serves as a middle ground with moderate density, offering a balance of flexibility and durability. LDPE, with its lower density, provides excellent flexibility and is perfect for wrapping and cushioning products. LLDPE, on the other hand, combines the benefits of LDPE's flexibility with enhanced strength and puncture resistance, making it suitable for safeguarding products with sharp edges or irregular shapes. These materials are integral to the anti-static foam packaging market, as they can be infused with anti-static properties to prevent static build-up, a critical requirement for packaging electronic components and devices. The choice of material depends on the specific requirements of the product being packaged, including weight, sensitivity to static electricity, and the level of protection needed against impacts during shipping.

Electronic, Automotive, Consumer Goods, Industrial Goods in the Anti-static Foam Packaging - Global Market:

The usage of anti-static foam packaging in the global market spans several key industries, including electronics, automotive, consumer goods, and industrial goods. In the electronics sector, this packaging is indispensable for protecting sensitive components like circuit boards, chips, and other electronic devices from static damage. Automotive manufacturers rely on anti-static foam to safeguard critical electronic parts and assemblies that are susceptible to static electricity, ensuring they reach the assembly line without incident. Consumer goods, ranging from household appliances to personal electronic devices, also benefit from the protective qualities of anti-static foam packaging, which helps maintain product integrity from the manufacturer to the end-user. In the industrial goods sector, this packaging solution is used to protect a wide array of products, including machinery parts and electronic components, that are critical to the operation of various industries. The versatility and effectiveness of anti-static foam packaging in preventing static-induced damage make it a preferred choice across these diverse sectors, highlighting its importance in the global market.

Anti-static Foam Packaging - Global Market Outlook:

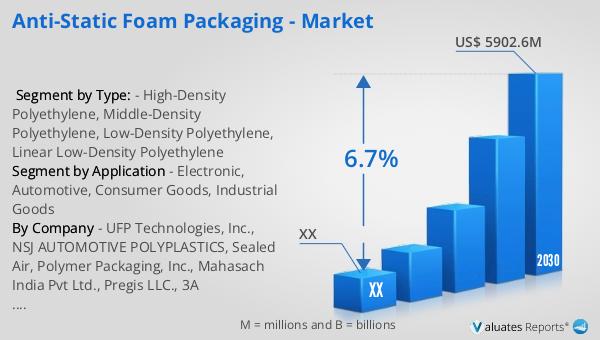

The outlook for the anti-static foam packaging market is promising, with projections indicating a significant growth trajectory. In 2023, the market was valued at approximately US$ 3760 million, and it's expected to expand to US$ 5902.6 million by 2030. This growth, estimated at a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2030, underscores the increasing demand for anti-static foam packaging solutions across various industries. Specifically, in North America, the market's value in 2023 sets the stage for continued expansion, with anticipated growth at a steady CAGR throughout the forecast period ending in 2030. This growth is driven by the critical need to protect sensitive electronic components and devices from static damage during shipping and handling, a concern that spans across global industries. The market's expansion reflects the broader trends in technology and electronics manufacturing, where the protection of components from electrostatic discharge is paramount.

| Report Metric | Details |

| Report Name | Anti-static Foam Packaging - Market |

| Forecasted market size in 2030 | US$ 5902.6 million |

| CAGR | 6.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | UFP Technologies, Inc., NSJ AUTOMOTIVE POLYPLASTICS, Sealed Air, Polymer Packaging, Inc., Mahasach India Pvt Ltd., Pregis LLC., 3A Manufacturing, Foam Converting, Raghav Industries, Surmount Industries, Kamatchi Packing Works, Battle Foam, Snehal-packaging, Starpack Overseas Private Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |