What is Aero Engine Coating - Global Market?

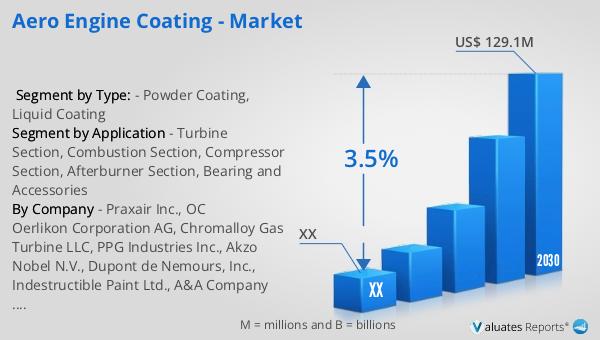

The global market for Aero Engine Coating is a niche yet significant segment within the aerospace industry, focusing on the application of advanced coatings to various engine components to enhance their performance, durability, and resistance to extreme conditions. As of 2023, this market was valued at approximately US$ 101.3 million and is projected to grow to US$ 129.1 million by 2030, marking a steady compound annual growth rate (CAGR) of 3.5% throughout the forecast period from 2024 to 2030. This growth trajectory is indicative of the increasing demand for more efficient, reliable, and longer-lasting aero engines, driven by the expanding global aviation sector. The North American region, in particular, has shown a robust performance in this market, starting with a significant valuation in 2023 and expected to continue its growth momentum up to 2030. This positive outlook is largely attributed to the technological advancements in coating materials and processes, as well as the growing emphasis on sustainability and environmental compliance in the aerospace industry. The strategic focus on enhancing engine efficiency while reducing maintenance costs and extending service life is a key driver behind the investments in aero engine coatings, making it a critical area of development for aerospace manufacturers and suppliers worldwide.

Powder Coating, Liquid Coating in the Aero Engine Coating - Global Market:

In the realm of the Aero Engine Coating global market, two primary types of coatings stand out: Powder Coating and Liquid Coating. Each type serves a unique purpose and offers distinct advantages, catering to the specific needs of aero engine components. Powder coatings are known for their exceptional durability and resistance to chipping, fading, and wearing, making them ideal for parts that endure high levels of stress and heat. This type of coating is applied as a free-flowing, dry powder and then cured under heat, creating a hard finish that is tougher than conventional paint. On the other hand, liquid coatings are valued for their versatility and superior finish quality. They can be applied to a wide range of substrates, including metals, plastics, and composites, making them suitable for various engine parts. Liquid coatings are particularly beneficial for components requiring a smooth, glossy finish or precise color matching. Both powder and liquid coatings play a crucial role in enhancing the performance, efficiency, and lifespan of aero engines by providing protection against corrosion, wear, and thermal degradation. The choice between powder and liquid coatings depends on several factors, including the specific application, desired properties, and environmental considerations. As the global market for Aero Engine Coating continues to evolve, advancements in coating technologies are expected to further improve the performance and sustainability of these critical aerospace components.

Turbine Section, Combustion Section, Compressor Section, Afterburner Section, Bearing and Accessories in the Aero Engine Coating - Global Market:

Aero Engine Coating finds its application across various sections of the engine, each serving a pivotal role in the overall performance and longevity of the engine. In the Turbine Section, coatings are applied to protect against the high temperatures and corrosive environments, thereby enhancing the durability and efficiency of the turbine blades and vanes. The Combustion Section, being exposed to extreme heat and oxidative conditions, benefits from coatings that can withstand such harsh environments, ensuring the integrity and performance of combustion chambers and other related components. For the Compressor Section, coatings are essential in minimizing wear and corrosion, thus maintaining optimal airflow and efficiency. The coatings applied here are designed to resist the abrasive particles ingested by the engine, ensuring the compressor blades and vanes maintain their aerodynamic profiles. In the Afterburner Section, where temperatures are exceedingly high, specialized coatings are used to protect against thermal degradation and to maintain structural integrity. Lastly, Bearings and Accessories, which include a wide range of engine parts such as gears, shafts, and seals, require coatings that can reduce friction, wear, and corrosion, thereby extending the service life of these components. The use of Aero Engine Coating in these areas is critical not only for the performance and efficiency of the engine but also for the safety and reliability of the aircraft.

Aero Engine Coating - Global Market Outlook:

The market outlook for Aero Engine Coating presents a promising future, with the industry's valuation set to increase from US$ 101.3 million in 2023 to US$ 129.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. This growth is indicative of the sector's resilience and its capacity to adapt to the evolving demands of the aerospace industry. The North American region, in particular, has demonstrated significant growth potential, starting from a strong market position in 2023 and projected to continue its upward trajectory through 2030. This positive outlook can be attributed to several factors, including advancements in coating technology, an increased focus on engine efficiency and durability, and a rising commitment to environmental sustainability within the aerospace sector. The strategic emphasis on improving engine performance while minimizing maintenance costs and extending the lifespan of aero engine components has been a key driver of investment and innovation in the Aero Engine Coating market. As the industry moves forward, these trends are expected to further shape the market dynamics, offering new opportunities for growth and development in the global aerospace arena.

| Report Metric | Details |

| Report Name | Aero Engine Coating - Market |

| Forecasted market size in 2030 | US$ 129.1 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Praxair Inc., OC Oerlikon Corporation AG, Chromalloy Gas Turbine LLC, PPG Industries Inc., Akzo Nobel N.V., Dupont de Nemours, Inc., Indestructible Paint Ltd., A&A Company Inc., APS Materials, Inc., Lincotek Group S.p.A. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |