What is Global Coatings and Inks pH Neutralizing Agent Market?

The Global Coatings and Inks pH Neutralizing Agent Market is a specialized segment within the broader chemical industry, focusing on agents that help maintain the pH balance in coatings and inks. These agents are crucial because they ensure the stability and performance of the final product. In coatings and inks, pH neutralizing agents are used to adjust and stabilize the pH level, which is vital for the optimal performance of the product. A balanced pH level helps in maintaining the viscosity, color, and overall quality of the coatings and inks. The market for these agents is driven by the increasing demand for high-quality coatings and inks in various industries such as automotive, construction, and packaging. As industries continue to grow and innovate, the need for effective pH neutralizing agents becomes more pronounced, leading to advancements in the formulations and applications of these agents. The market is characterized by a mix of established players and new entrants, all striving to offer more efficient and environmentally friendly solutions. With the ongoing emphasis on sustainability and performance, the Global Coatings and Inks pH Neutralizing Agent Market is poised for significant growth and innovation in the coming years.

Inorganic, Organic in the Global Coatings and Inks pH Neutralizing Agent Market:

In the Global Coatings and Inks pH Neutralizing Agent Market, inorganic and organic agents play pivotal roles in maintaining the desired pH levels in various formulations. Inorganic pH neutralizing agents, such as ammonia and sodium hydroxide, are widely used due to their effectiveness and cost-efficiency. These agents are typically employed in water-based coatings and inks, where they help in stabilizing the pH without significantly altering the other properties of the formulation. Inorganic agents are known for their strong neutralizing capabilities, which make them suitable for applications requiring rapid pH adjustments. However, they can sometimes lead to issues such as corrosion or unwanted reactions if not used carefully. On the other hand, organic pH neutralizing agents, including amines and amino alcohols, offer a more refined approach to pH stabilization. These agents are often preferred in formulations where a more controlled and gradual pH adjustment is needed. Organic agents are particularly valued for their ability to enhance the performance characteristics of coatings and inks, such as improving gloss, adhesion, and durability. They are also favored in applications where environmental and safety considerations are paramount, as many organic agents are less volatile and have lower toxicity compared to their inorganic counterparts. The choice between inorganic and organic pH neutralizing agents often depends on the specific requirements of the application, including factors such as the type of substrate, desired performance characteristics, and regulatory considerations. In recent years, there has been a growing trend towards the use of organic agents, driven by the increasing demand for sustainable and eco-friendly solutions in the coatings and inks industry. This shift is also influenced by the tightening of environmental regulations, which encourage the use of less hazardous chemicals. Despite the advantages of organic agents, inorganic agents continue to hold a significant share of the market due to their cost-effectiveness and proven track record in various applications. The ongoing research and development efforts in the field are focused on enhancing the performance and environmental profile of both inorganic and organic pH neutralizing agents. Innovations such as hybrid agents, which combine the benefits of both inorganic and organic compounds, are also being explored to meet the evolving needs of the industry. As the Global Coatings and Inks pH Neutralizing Agent Market continues to evolve, the interplay between inorganic and organic agents will remain a key area of focus, with manufacturers striving to offer solutions that balance performance, cost, and sustainability.

Coatings, Inks in the Global Coatings and Inks pH Neutralizing Agent Market:

The usage of Global Coatings and Inks pH Neutralizing Agents in coatings and inks is integral to ensuring the quality and performance of these products. In the coatings industry, pH neutralizing agents are used to maintain the stability of water-based coatings, which are increasingly popular due to their lower environmental impact compared to solvent-based alternatives. These agents help in adjusting the pH to an optimal level, which is crucial for the stability of the emulsion and the prevention of issues such as coagulation or phase separation. A well-balanced pH also contributes to the overall performance of the coating, including its adhesion, gloss, and resistance to environmental factors. In the inks industry, pH neutralizing agents play a similar role in maintaining the stability and performance of water-based inks. These agents ensure that the pH remains within a range that prevents the degradation of the ink components, which can lead to issues such as color shifts or reduced print quality. The use of pH neutralizing agents in inks is particularly important in applications where precision and consistency are critical, such as in the printing of packaging materials or high-quality graphics. In both coatings and inks, the choice of pH neutralizing agent can have a significant impact on the final product. Factors such as the type of substrate, the desired performance characteristics, and environmental considerations all play a role in determining the most suitable agent for a given application. For instance, in applications where environmental and safety considerations are paramount, organic pH neutralizing agents may be preferred due to their lower toxicity and reduced environmental impact. Conversely, in applications where cost is a major consideration, inorganic agents may be favored for their cost-effectiveness and strong neutralizing capabilities. The ongoing advancements in the field of pH neutralizing agents are focused on developing solutions that offer enhanced performance while minimizing environmental impact. This includes the development of new formulations that combine the benefits of both inorganic and organic agents, as well as the exploration of novel compounds that offer improved stability and performance. As the demand for high-quality coatings and inks continues to grow, the role of pH neutralizing agents in ensuring the stability and performance of these products will remain critical. Manufacturers and formulators will continue to seek out innovative solutions that meet the evolving needs of the industry, balancing performance, cost, and sustainability in their choice of pH neutralizing agents.

Global Coatings and Inks pH Neutralizing Agent Market Outlook:

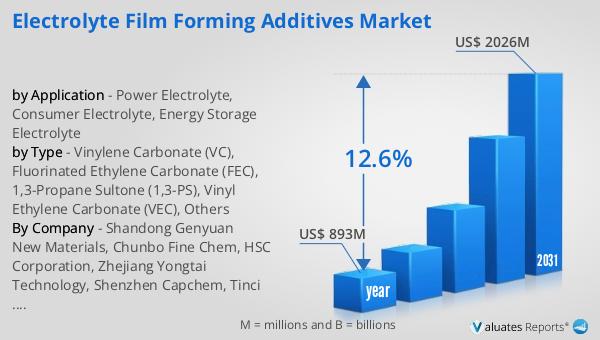

The global market for Coatings and Inks pH Neutralizing Agents was valued at $153 million in 2024, and it is anticipated to expand to a revised size of $222 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% over the forecast period. This growth trajectory underscores the increasing demand for pH neutralizing agents in the coatings and inks industry, driven by the need for high-quality, stable, and environmentally friendly products. The market's expansion is fueled by the rising adoption of water-based formulations, which require effective pH management to ensure optimal performance. As industries such as automotive, construction, and packaging continue to grow, the demand for advanced coatings and inks that meet stringent quality and environmental standards is expected to rise. This, in turn, drives the need for efficient pH neutralizing agents that can maintain the stability and performance of these products. The market is characterized by a diverse range of players, from established chemical companies to innovative startups, all striving to offer solutions that meet the evolving needs of the industry. As the market continues to grow, the focus will remain on developing pH neutralizing agents that offer a balance of performance, cost-effectiveness, and sustainability, ensuring that the coatings and inks industry can continue to innovate and meet the demands of a rapidly changing world.

| Report Metric | Details |

| Report Name | Coatings and Inks pH Neutralizing Agent Market |

| Accounted market size in year | US$ 153 million |

| Forecasted market size in 2031 | US$ 222 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eastman Chemical, Dow, CLARIANT, BASF SE, Ashland, Hydrite Chemical, Rxchemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |