What is Global Fine Zinc Powder Market?

The Global Fine Zinc Powder Market is a significant segment within the broader zinc industry, focusing on the production and distribution of finely milled zinc particles. These powders are characterized by their small particle size, which enhances their reactivity and utility in various applications. Fine zinc powder is primarily used in industries such as coatings, chemicals, and pharmaceuticals due to its excellent anti-corrosive properties and ability to act as a reducing agent. The market is driven by the increasing demand for high-performance coatings, especially in sectors like marine and architectural, where protection against corrosion is crucial. Additionally, the rise in industrial activities and the need for sustainable and efficient materials further propel the market's growth. The global reach of this market is evident as it caters to diverse industries across different regions, adapting to the specific needs and standards of each. As industries continue to evolve and seek more efficient materials, the demand for fine zinc powder is expected to grow, highlighting its importance in modern industrial applications. The market's expansion is also supported by technological advancements in production processes, ensuring high-quality and consistent products for end-users.

1000 Mesh Zinc Powder, 800 Mesh Zinc Powder, 500 Mesh Zinc Powder, 200 Mesh Zinc Powder, Others in the Global Fine Zinc Powder Market:

In the Global Fine Zinc Powder Market, different mesh sizes of zinc powder cater to various industrial needs, each offering unique properties and applications. Starting with the 1000 Mesh Zinc Powder, this ultra-fine powder is highly sought after for its superior reactivity and surface area. Its fine particle size makes it ideal for applications requiring high precision and uniformity, such as in the electronics industry for conductive pastes and in specialized coatings where a smooth finish is paramount. The 800 Mesh Zinc Powder, slightly coarser than the 1000 mesh, finds its niche in applications where a balance between reactivity and cost is essential. It is commonly used in the production of zinc-rich paints and primers, providing excellent anti-corrosive properties for steel structures exposed to harsh environments. Moving to the 500 Mesh Zinc Powder, this variant is often utilized in the chemical industry as a reducing agent and in the production of zinc-based compounds. Its particle size offers a good compromise between surface area and flowability, making it suitable for various chemical processes. The 200 Mesh Zinc Powder, with its larger particle size, is typically used in applications where high reactivity is not the primary concern. It is often employed in the metallurgical industry for galvanizing and in the production of zinc alloys. This coarser powder is also used in the manufacturing of brake linings and friction materials, where its physical properties contribute to the desired performance characteristics. Beyond these specific mesh sizes, the market also includes other variants tailored to meet specific industrial requirements. These may include customized blends or powders with specific coatings to enhance their performance in particular applications. The diversity in mesh sizes and the ability to customize zinc powders highlight the market's adaptability to the evolving needs of various industries. As industries continue to innovate and seek materials that offer both performance and sustainability, the demand for fine zinc powders of different mesh sizes is expected to remain robust. The ongoing research and development efforts in this field aim to further enhance the properties of zinc powders, ensuring they meet the stringent requirements of modern industrial applications.

Marine Coatings, Container Coatings, Architectural Coatings, Petrochemical Coatings, Chemicals, Pharmaceuticals and Food, Others in the Global Fine Zinc Powder Market:

The Global Fine Zinc Powder Market plays a crucial role in various industries, providing essential materials for a wide range of applications. In the realm of Marine Coatings, fine zinc powder is indispensable due to its excellent anti-corrosive properties. Ships and offshore structures are constantly exposed to harsh marine environments, making corrosion a significant concern. Zinc powder-based coatings provide a protective barrier, extending the lifespan of these structures and reducing maintenance costs. Similarly, in Container Coatings, zinc powder is used to protect shipping containers from rust and corrosion, ensuring the safe transport of goods across long distances. Architectural Coatings also benefit from the use of fine zinc powder. Buildings and infrastructure require durable coatings to withstand environmental factors such as rain, humidity, and pollution. Zinc powder enhances the longevity and aesthetic appeal of architectural coatings, making them a preferred choice for modern construction projects. In the Petrochemical Coatings sector, the demand for fine zinc powder is driven by the need to protect pipelines, storage tanks, and other equipment from corrosive chemicals. The powder's ability to form a protective layer helps prevent leaks and extends the service life of critical infrastructure. Beyond coatings, the Global Fine Zinc Powder Market finds applications in the Chemicals industry, where it serves as a reducing agent in various chemical reactions. Its reactivity and purity make it an ideal choice for producing high-quality chemical products. In the Pharmaceuticals and Food sectors, zinc powder is used in the formulation of dietary supplements and as a nutrient fortification agent. Its role in promoting health and wellness underscores its importance in these industries. Additionally, zinc powder is used in the production of zinc oxide, a key ingredient in sunscreens and cosmetics, further highlighting its versatility. The market also caters to other niche applications, such as in the production of batteries, where zinc powder is used as an anode material. Its high energy density and stability make it suitable for use in various battery technologies, including alkaline and zinc-air batteries. As industries continue to evolve and seek materials that offer both performance and sustainability, the demand for fine zinc powder is expected to grow. The market's ability to adapt to the specific needs of different sectors ensures its continued relevance in the global industrial landscape.

Global Fine Zinc Powder Market Outlook:

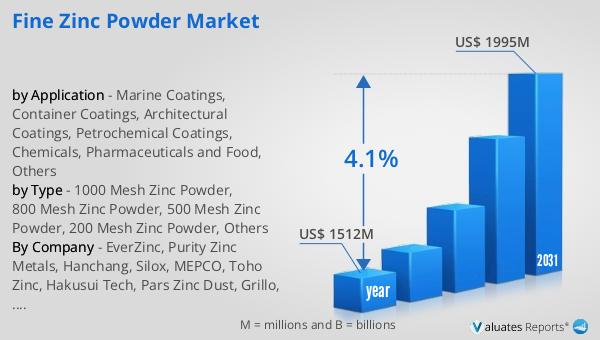

The outlook for the Global Fine Zinc Powder Market indicates a promising future, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $1,512 million, reflecting its substantial role in various industrial applications. By 2031, projections suggest that the market will expand to a revised size of around $1,995 million. This growth trajectory represents a compound annual growth rate (CAGR) of 4.1% during the forecast period. Such a steady increase underscores the rising demand for fine zinc powder across multiple sectors, driven by its versatile applications and the ongoing need for high-performance materials. The market's expansion is supported by technological advancements in production processes, which enhance the quality and consistency of zinc powders. Additionally, the increasing focus on sustainability and the development of eco-friendly products contribute to the market's growth. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the demand for fine zinc powder is expected to remain robust. The market's ability to adapt to the evolving needs of different sectors ensures its continued relevance and importance in the global industrial landscape. With its wide range of applications and the ongoing efforts to improve its properties, fine zinc powder is poised to play a crucial role in the future of various industries.

| Report Metric | Details |

| Report Name | Fine Zinc Powder Market |

| Accounted market size in year | US$ 1512 million |

| Forecasted market size in 2031 | US$ 1995 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EverZinc, Purity Zinc Metals, Hanchang, Silox, MEPCO, Toho Zinc, Hakusui Tech, Pars Zinc Dust, Grillo, Jiangsu Kecheng, Yunan Luoping Zinc &Electricity, Shijiazhuang Xinri Zinc, Jiangsu Shenlong Zinc, Shandong Xingyuan Zinc, Jiangsu Shuangsheng, Jiangsu Yejian Zinc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |