What is Global Physical Vapor Deposition Market?

The Global Physical Vapor Deposition (PVD) Market is a fascinating segment of the broader materials processing industry. PVD is a vacuum deposition method used to produce thin films and coatings. This process involves the physical transfer of material from a condensed phase to a vapor phase and then back to a thin film condensed phase. The global market for PVD is driven by its extensive applications across various industries, including electronics, automotive, aerospace, and healthcare. The demand for PVD is primarily fueled by its ability to enhance the durability, appearance, and performance of products. It is a preferred method due to its environmentally friendly nature, as it does not produce hazardous waste. The market is characterized by continuous technological advancements and innovations aimed at improving the efficiency and effectiveness of PVD processes. As industries increasingly seek sustainable and high-performance coating solutions, the PVD market is poised for significant growth. The market's expansion is also supported by the rising demand for miniaturized electronic components and the growing trend of lightweight materials in automotive and aerospace sectors. Overall, the Global Physical Vapor Deposition Market is a dynamic and evolving field with promising prospects for the future.

PVD Equipment, PVD Materials, PVD Services in the Global Physical Vapor Deposition Market:

PVD Equipment, PVD Materials, and PVD Services are integral components of the Global Physical Vapor Deposition Market, each playing a crucial role in the overall process and application of PVD technology. PVD Equipment refers to the machinery and tools used to carry out the PVD process. This includes vacuum chambers, deposition sources, and substrate holders, among others. The equipment is designed to create the necessary conditions for the vaporization and deposition of materials onto substrates. The efficiency and precision of PVD equipment are vital for achieving high-quality coatings, and advancements in equipment technology are continually enhancing the capabilities of PVD processes. PVD Materials, on the other hand, are the substances that are vaporized and deposited onto substrates. These materials can include metals, alloys, ceramics, and other compounds, chosen based on the desired properties of the final coating. The selection of PVD materials is critical as it determines the characteristics of the coating, such as hardness, adhesion, and resistance to wear and corrosion. The development of new materials and material combinations is a key area of research and innovation within the PVD market. PVD Services encompass the application of PVD technology by specialized service providers. These services are often sought by industries that require high-performance coatings but do not have the in-house capability to perform PVD processes. PVD service providers offer expertise in selecting appropriate materials, optimizing process parameters, and ensuring quality control. They play a vital role in making PVD technology accessible to a broader range of industries and applications. The synergy between PVD Equipment, Materials, and Services is essential for the successful implementation of PVD technology across various sectors. Each component contributes to the overall effectiveness and efficiency of the PVD process, enabling industries to achieve superior coatings that enhance product performance and longevity. As the demand for advanced coatings continues to grow, the interplay between these components will be crucial in driving the evolution and expansion of the Global Physical Vapor Deposition Market.

Microelectronics, Solar, Medical Equipment, Cutting Tools in the Global Physical Vapor Deposition Market:

The Global Physical Vapor Deposition Market finds extensive usage across several key areas, including Microelectronics, Solar, Medical Equipment, and Cutting Tools, each benefiting from the unique advantages offered by PVD technology. In the realm of Microelectronics, PVD is instrumental in the fabrication of semiconductor devices and integrated circuits. The ability of PVD to deposit thin films with precise control over thickness and composition makes it ideal for creating the intricate layers required in microelectronic components. This precision is crucial for the performance and reliability of electronic devices, driving the demand for PVD in this sector. In the Solar industry, PVD is used to produce thin-film solar cells, which are an alternative to traditional silicon-based cells. The thin films created through PVD can be applied to flexible substrates, allowing for lightweight and versatile solar panels. This flexibility is particularly advantageous for applications where traditional solar panels are impractical. PVD's role in enhancing the efficiency and reducing the cost of solar cells is a significant factor in the growth of its application in this industry. In the Medical Equipment sector, PVD coatings are used to improve the performance and longevity of medical devices and implants. The biocompatibility and wear resistance of PVD coatings make them suitable for applications such as surgical instruments, orthopedic implants, and dental tools. These coatings help reduce friction, enhance durability, and prevent corrosion, which are critical factors in the medical field. The demand for high-quality, reliable medical equipment continues to drive the adoption of PVD technology in this area. Cutting Tools benefit from PVD coatings due to their ability to enhance hardness and wear resistance. PVD coatings extend the life of cutting tools, improve their performance, and reduce the need for frequent replacements. This is particularly important in industries such as manufacturing and automotive, where cutting tools are subjected to high levels of stress and wear. The use of PVD in cutting tools contributes to increased efficiency and cost savings, making it a valuable application of the technology. Overall, the Global Physical Vapor Deposition Market plays a vital role in advancing technology and innovation across these diverse sectors, offering solutions that enhance performance, efficiency, and sustainability.

Global Physical Vapor Deposition Market Outlook:

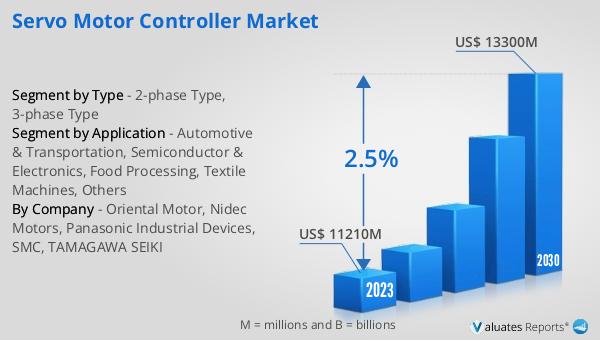

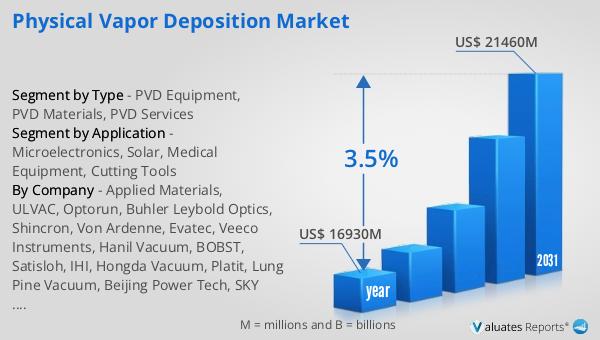

In 2024, the global market for Physical Vapor Deposition was valued at approximately $16.93 billion. Looking ahead, this market is anticipated to expand, reaching an estimated size of $21.46 billion by the year 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.5% over the forecast period. The steady increase in market size underscores the rising demand for PVD technology across various industries. This demand is driven by the need for advanced coating solutions that enhance product performance and durability. As industries continue to prioritize sustainability and efficiency, the adoption of PVD technology is expected to grow. The market's expansion is also supported by ongoing advancements in PVD equipment and materials, which are enhancing the capabilities and applications of this technology. The projected growth of the Global Physical Vapor Deposition Market highlights the importance of PVD as a key enabler of innovation and competitiveness in today's rapidly evolving industrial landscape. As the market continues to evolve, it will play a crucial role in shaping the future of materials processing and coating technologies.

| Report Metric | Details |

| Report Name | Physical Vapor Deposition Market |

| Accounted market size in year | US$ 16930 million |

| Forecasted market size in 2031 | US$ 21460 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Applied Materials, ULVAC, Optorun, Buhler Leybold Optics, Shincron, Von Ardenne, Evatec, Veeco Instruments, Hanil Vacuum, BOBST, Satisloh, IHI, Hongda Vacuum, Platit, Lung Pine Vacuum, Beijing Power Tech, SKY Technology, Impact Coatings, HCVAC, Denton Vacuum, ZHEN HUA, Mustang Vacuum Systems, KYZK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |