What is Global Computer Numerical Controls (CNC) Market?

The Global Computer Numerical Controls (CNC) Market refers to the worldwide industry focused on the development, production, and distribution of CNC machines. These machines are automated control systems that use computer programming to manage the movement of machinery and tools. CNC technology is essential in manufacturing because it allows for precise control over complex machinery, leading to increased efficiency and accuracy in production processes. The market encompasses a wide range of industries, including automotive, aerospace, electronics, and more, as these sectors rely heavily on CNC machines for their manufacturing needs. The growth of this market is driven by the increasing demand for high-quality products, the need for automation in manufacturing processes, and advancements in technology that enhance the capabilities of CNC machines. As industries continue to seek ways to improve productivity and reduce costs, the adoption of CNC technology is expected to rise, further expanding the market. The global CNC market is characterized by a diverse range of products and services, catering to various industrial applications and requirements. This market is also influenced by factors such as technological innovations, economic conditions, and regulatory policies that impact the manufacturing sector.

Milling Machines, Lathe Machines, Grinding Units, Lasers, Winding Machines, Welding Machines, Others in the Global Computer Numerical Controls (CNC) Market:

Milling machines are a crucial component of the Global CNC Market, designed to perform a variety of operations such as cutting, drilling, and shaping materials like metal, wood, and plastic. These machines use rotary cutters to remove material from a workpiece, allowing for the creation of complex shapes and designs with high precision. In the CNC market, milling machines are valued for their versatility and ability to produce intricate parts with minimal human intervention. Lathe machines, on the other hand, are used to shape cylindrical objects by rotating the workpiece against a cutting tool. CNC lathe machines are highly efficient and capable of producing precise components for industries such as automotive and aerospace. Grinding units in the CNC market are employed to achieve fine finishes and tight tolerances on workpieces. These machines use abrasive wheels to remove material and are essential for applications requiring high surface quality. Lasers in the CNC market are used for cutting, engraving, and marking materials with exceptional precision and speed. CNC laser machines are popular in industries like electronics and automotive, where intricate designs and high-quality finishes are required. Winding machines are specialized CNC equipment used in the production of coils and windings for electrical components. These machines ensure consistent winding patterns and are crucial for the manufacturing of transformers, motors, and generators. Welding machines in the CNC market automate the welding process, providing consistent and high-quality welds for various applications. These machines are widely used in industries such as construction, automotive, and shipbuilding. Other CNC machines include routers, plasma cutters, and waterjet cutters, each serving specific purposes in the manufacturing process. CNC routers are used for cutting and shaping materials like wood, plastic, and composites, while plasma cutters are employed for cutting metal with high precision. Waterjet cutters use high-pressure water streams to cut materials without generating heat, making them suitable for heat-sensitive applications. The diversity of CNC machines in the global market reflects the wide range of industrial needs and the continuous advancements in technology that drive innovation and efficiency in manufacturing processes.

Industrial, Automotive, Defense & Aerospace, Power & Energy, Others in the Global Computer Numerical Controls (CNC) Market:

The usage of Global CNC Market technology spans across various industries, each benefiting from the precision, efficiency, and automation that CNC machines provide. In the industrial sector, CNC machines are integral to the production of components and products across a wide range of applications. They enable manufacturers to produce high-quality parts with minimal waste and reduced labor costs, leading to increased productivity and competitiveness. The automotive industry relies heavily on CNC technology for the production of engine components, transmission parts, and other critical elements of vehicles. CNC machines ensure that these parts meet stringent quality standards and are produced with high precision, contributing to the overall performance and safety of vehicles. In the defense and aerospace sectors, CNC machines are used to manufacture complex components for aircraft, missiles, and other defense equipment. The precision and reliability of CNC technology are crucial in these industries, where the quality and performance of components can have significant implications for safety and effectiveness. The power and energy sector also benefits from CNC technology, particularly in the production of components for turbines, generators, and other energy-related equipment. CNC machines enable the production of parts with tight tolerances and high-quality finishes, ensuring the efficient operation of energy systems. Other industries, such as electronics, medical devices, and consumer goods, also utilize CNC technology to produce a wide range of products. In electronics, CNC machines are used to manufacture circuit boards and other components with high precision. In the medical field, CNC technology is employed to produce surgical instruments, implants, and other medical devices that require exact specifications and high-quality finishes. The consumer goods industry uses CNC machines to produce items such as furniture, appliances, and sporting equipment, where precision and quality are essential. Overall, the Global CNC Market plays a vital role in modern manufacturing, providing the tools and technology needed to produce high-quality products across a diverse range of industries. The continued advancement of CNC technology is expected to drive further innovation and efficiency in manufacturing processes, supporting the growth and development of various sectors worldwide.

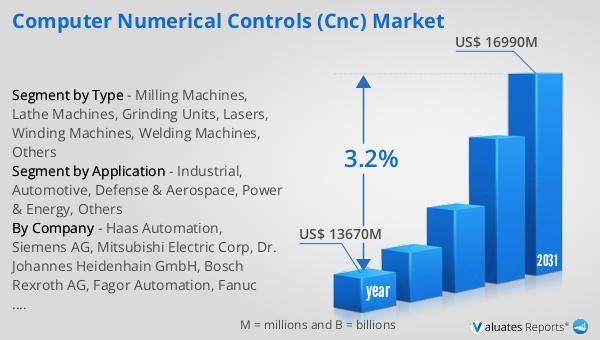

Global Computer Numerical Controls (CNC) Market Outlook:

The global market for Computer Numerical Controls (CNC) was valued at $13,670 million in 2024 and is anticipated to grow to a revised size of $16,990 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth trajectory highlights the increasing demand for CNC technology across various industries, driven by the need for precision, efficiency, and automation in manufacturing processes. As industries continue to evolve and seek ways to enhance productivity and reduce costs, the adoption of CNC machines is expected to rise, contributing to the market's expansion. The projected growth of the CNC market underscores the importance of technological advancements and innovation in driving the development of new and improved CNC machines. These advancements enable manufacturers to produce high-quality products with greater accuracy and efficiency, meeting the demands of a competitive global market. The CNC market's growth is also influenced by factors such as economic conditions, regulatory policies, and industry trends that impact the manufacturing sector. As the market continues to expand, it presents opportunities for businesses to invest in CNC technology and capitalize on the benefits it offers in terms of improved productivity, reduced waste, and enhanced product quality. The future of the CNC market looks promising, with continued growth and development expected as industries increasingly rely on CNC technology to meet their manufacturing needs.

| Report Metric | Details |

| Report Name | Computer Numerical Controls (CNC) Market |

| Accounted market size in year | US$ 13670 million |

| Forecasted market size in 2031 | US$ 16990 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Haas Automation, Siemens AG, Mitsubishi Electric Corp, Dr. Johannes Heidenhain GmbH, Bosch Rexroth AG, Fagor Automation, Fanuc Corporation, GSK CNC EQUIPMENT, Soft Servo Systems, Sieb & Meyer AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |