What is Global Lab Freezer Mill Market?

The Global Lab Freezer Mill Market is a specialized segment within the broader laboratory equipment industry, focusing on devices designed to grind and pulverize samples at cryogenic temperatures. These mills are essential for laboratories that require precise and efficient sample preparation, particularly when dealing with tough, elastic, or temperature-sensitive materials. By using liquid nitrogen to maintain low temperatures, lab freezer mills prevent the degradation of samples, ensuring that their chemical composition remains unchanged during the grinding process. This is crucial for obtaining accurate and reliable results in various scientific analyses. The market for these mills is driven by the increasing demand for advanced research and development activities across multiple sectors, including pharmaceuticals, biotechnology, and materials science. As laboratories strive for higher precision and efficiency, the adoption of lab freezer mills is expected to grow, supported by technological advancements and the need for improved sample preparation techniques. The market is characterized by a range of products catering to different laboratory needs, from small-scale research facilities to large industrial labs, each offering unique features and capabilities to meet specific requirements.

Small Size, Large Size, Medium Size in the Global Lab Freezer Mill Market:

In the Global Lab Freezer Mill Market, the size of the equipment plays a crucial role in determining its application and suitability for various laboratory settings. Small-sized lab freezer mills are typically designed for use in research and academic laboratories where space is limited, and the volume of samples processed is relatively low. These compact units are ideal for handling small batches of samples, making them perfect for individual researchers or small teams conducting preliminary studies or experiments. Despite their size, these mills are equipped with advanced features that ensure efficient grinding and sample preservation, making them a valuable asset for any laboratory focused on precision and accuracy. Medium-sized lab freezer mills, on the other hand, are more versatile and can accommodate a wider range of sample sizes and types. They are commonly used in mid-sized laboratories that require a balance between capacity and space efficiency. These mills offer enhanced capabilities, such as adjustable grinding parameters and increased throughput, allowing laboratories to process larger volumes of samples without compromising on quality. This makes them suitable for a variety of applications, from routine sample preparation to more complex research projects. Large-sized lab freezer mills are designed for high-capacity laboratories and industrial settings where the demand for sample processing is significantly higher. These robust machines are capable of handling large batches of samples, making them ideal for large-scale research projects or production environments. With advanced automation features and high throughput capabilities, large-sized mills ensure efficient and consistent sample preparation, even under demanding conditions. They are often used in industries such as pharmaceuticals, biotechnology, and materials science, where the need for precise and reliable sample analysis is critical. The choice between small, medium, and large-sized lab freezer mills ultimately depends on the specific needs and constraints of the laboratory, including available space, budget, and the volume of samples to be processed. Each size category offers unique advantages, allowing laboratories to select the most appropriate equipment to meet their research and operational goals. As the demand for advanced laboratory equipment continues to grow, manufacturers are focusing on developing innovative solutions that cater to the diverse needs of the global market, ensuring that laboratories have access to the best tools for their specific applications.

Biomedical Laboratory, Forensic Science Laboratory, Other in the Global Lab Freezer Mill Market:

The Global Lab Freezer Mill Market finds extensive usage across various fields, including biomedical laboratories, forensic science laboratories, and other specialized research areas. In biomedical laboratories, lab freezer mills are indispensable tools for preparing biological samples, such as tissues, cells, and DNA, for analysis. These mills ensure that samples are ground to a fine powder without altering their chemical composition, which is crucial for accurate and reliable results in genetic studies, drug development, and disease research. By maintaining low temperatures during the grinding process, lab freezer mills prevent the degradation of sensitive biomolecules, preserving the integrity of the samples for downstream applications. In forensic science laboratories, lab freezer mills play a vital role in the preparation of evidence samples for analysis. Forensic scientists often deal with complex and challenging samples, such as bones, hair, and fibers, which require precise and efficient grinding to extract valuable information. Lab freezer mills provide the necessary capabilities to process these samples without compromising their integrity, enabling forensic experts to obtain accurate and reliable results in criminal investigations. The ability to preserve the chemical composition of samples during grinding is particularly important in forensic science, where even the slightest alteration can impact the outcome of an investigation. Beyond biomedical and forensic applications, lab freezer mills are also used in various other research fields, including materials science, environmental studies, and food analysis. In materials science, these mills are employed to prepare samples for the analysis of polymers, ceramics, and metals, ensuring that the samples are ground to a consistent particle size for accurate characterization. In environmental studies, lab freezer mills are used to process soil, plant, and water samples, enabling researchers to study the impact of pollutants and other environmental factors on ecosystems. In the food industry, these mills are used to analyze the composition and quality of food products, ensuring compliance with safety and quality standards. The versatility and efficiency of lab freezer mills make them an essential tool for laboratories across various disciplines, supporting a wide range of research and analytical applications. As the demand for advanced research and development continues to grow, the usage of lab freezer mills is expected to expand, driven by the need for precise and reliable sample preparation techniques.

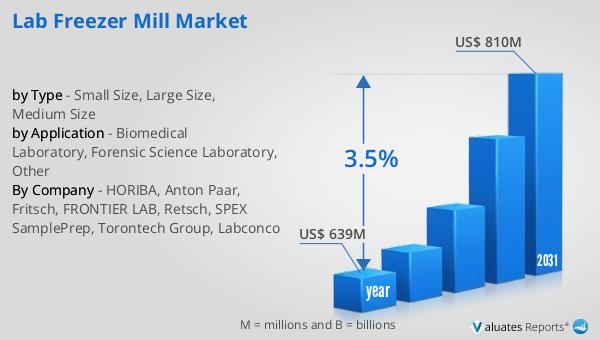

Global Lab Freezer Mill Market Outlook:

The outlook for the Global Lab Freezer Mill Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately $639 million, reflecting the significant demand for these specialized laboratory devices. By 2031, the market is anticipated to reach an estimated size of $810 million, driven by a compound annual growth rate (CAGR) of 3.5% during the forecast period. This growth can be attributed to several factors, including the increasing emphasis on research and development activities across various industries, such as pharmaceuticals, biotechnology, and materials science. As laboratories strive for higher precision and efficiency in sample preparation, the adoption of lab freezer mills is expected to rise, supported by technological advancements and the need for improved analytical techniques. The market's expansion is also fueled by the growing demand for advanced laboratory equipment in emerging economies, where research infrastructure is rapidly developing. Additionally, the increasing focus on personalized medicine and the need for accurate and reliable sample analysis in drug development and disease research are expected to further drive the demand for lab freezer mills. As a result, manufacturers are investing in the development of innovative solutions that cater to the diverse needs of the global market, ensuring that laboratories have access to the best tools for their specific applications.

| Report Metric | Details |

| Report Name | Lab Freezer Mill Market |

| Accounted market size in year | US$ 639 million |

| Forecasted market size in 2031 | US$ 810 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HORIBA, Anton Paar, Fritsch, FRONTIER LAB, Retsch, SPEX SamplePrep, Torontech Group, Labconco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |