What is Global Press Fit Machines Market?

The Global Press Fit Machines Market is a specialized segment within the manufacturing industry that focuses on machines designed to insert components into printed circuit boards (PCBs) without the need for soldering. These machines are crucial in industries where precision and reliability are paramount, such as automotive, consumer electronics, and telecommunications. Press fit technology involves inserting a pin into a plated through-hole on a PCB, where the mechanical force ensures a reliable electrical connection. This method is favored for its ability to create strong, durable connections that can withstand environmental stresses and vibrations. The market for press fit machines is driven by the increasing demand for miniaturized electronic devices and the need for high-density interconnections. As technology advances, the complexity and functionality of electronic devices increase, necessitating more sophisticated manufacturing techniques. Press fit machines offer a solution by providing high-speed, accurate, and repeatable insertion processes, which are essential for maintaining the quality and performance of modern electronic products. The market is characterized by continuous innovation, with manufacturers focusing on enhancing machine capabilities to meet the evolving needs of various industries.

Semi-Automatic Press Fit Machines, Automatic Press Fit Machines in the Global Press Fit Machines Market:

Semi-automatic and automatic press fit machines are two primary types of equipment used in the Global Press Fit Machines Market, each offering distinct advantages and features. Semi-automatic press fit machines require some level of human intervention during the operation. These machines are typically used in scenarios where flexibility and adaptability are needed, as they allow operators to manually adjust settings and oversee the insertion process. This type of machine is ideal for small to medium-sized production runs or for applications where customization is necessary. Operators can easily switch between different components or adjust the machine for varying board designs, making semi-automatic machines a versatile choice for manufacturers who need to accommodate a wide range of products. On the other hand, automatic press fit machines are designed for high-volume production environments where speed and efficiency are critical. These machines operate with minimal human intervention, using advanced robotics and control systems to perform the insertion process. Automatic machines are equipped with features such as automated component feeding, precise alignment systems, and real-time monitoring capabilities, ensuring consistent quality and high throughput. They are particularly beneficial in industries where large-scale production is required, such as automotive and consumer electronics, where the demand for electronic components is high. The choice between semi-automatic and automatic press fit machines depends largely on the specific needs of the manufacturer, including production volume, product complexity, and budget constraints. While semi-automatic machines offer greater flexibility and lower initial costs, automatic machines provide superior efficiency and consistency, making them a preferred choice for large-scale operations. Both types of machines play a crucial role in the Global Press Fit Machines Market, catering to the diverse needs of manufacturers across various industries. As technology continues to evolve, the capabilities of these machines are expected to expand, offering even greater precision and efficiency in the manufacturing process.

Automotive, Consumer Electronics, Telecommunication, Others in the Global Press Fit Machines Market:

The Global Press Fit Machines Market finds extensive application across several key industries, including automotive, consumer electronics, telecommunications, and others. In the automotive industry, press fit machines are used to assemble various electronic components that are integral to modern vehicles. With the increasing complexity of automotive electronics, such as advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle components, the demand for reliable and efficient assembly processes is on the rise. Press fit technology provides the necessary precision and durability required for these applications, ensuring that electronic connections can withstand the harsh conditions often encountered in automotive environments. In the consumer electronics sector, press fit machines are essential for the production of compact and high-performance devices. As consumer demand for smaller, more powerful gadgets continues to grow, manufacturers are challenged to develop innovative solutions that maximize space and functionality. Press fit machines enable the production of densely packed circuit boards, which are crucial for devices like smartphones, tablets, and wearable technology. The ability to create strong, solderless connections also enhances the reliability and longevity of these products, meeting consumer expectations for quality and performance. In the telecommunications industry, press fit machines are used to assemble components for network infrastructure and communication devices. With the rapid expansion of 5G networks and the increasing demand for high-speed internet connectivity, the need for robust and efficient assembly processes is more critical than ever. Press fit technology offers a reliable solution for creating high-density interconnections, which are essential for supporting the advanced capabilities of modern telecommunications equipment. Beyond these primary industries, press fit machines are also utilized in various other sectors, including aerospace, medical devices, and industrial equipment. In each of these areas, the ability to produce precise and durable electronic connections is vital for ensuring the performance and reliability of complex systems. As the Global Press Fit Machines Market continues to grow, its applications are expected to expand, driven by ongoing advancements in technology and the increasing demand for sophisticated electronic devices across multiple industries.

Global Press Fit Machines Market Outlook:

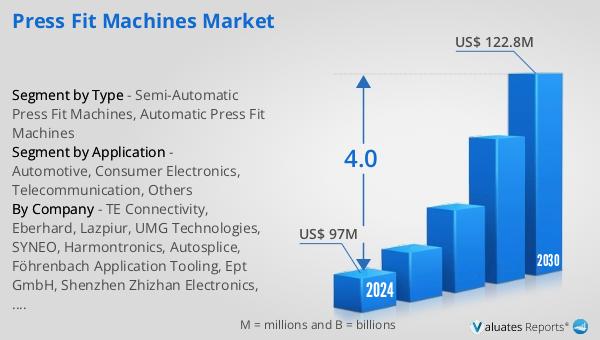

The global market for Press Fit Machines was valued at approximately USD 101 million in 2024, with projections indicating an increase to around USD 132 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. This steady growth trajectory underscores the increasing demand for press fit machines across various industries, driven by the need for efficient and reliable assembly processes in the production of electronic components. The market is characterized by a high level of concentration, with the top five manufacturers accounting for over 60% of the market share. This concentration highlights the competitive nature of the industry, where leading companies are continually innovating to maintain their market positions. These manufacturers are focused on enhancing the capabilities of press fit machines, incorporating advanced technologies to improve precision, speed, and efficiency. As the market evolves, these companies are likely to play a pivotal role in shaping the future of press fit technology, driving further advancements and expanding the applications of these machines across different sectors. The growth of the Global Press Fit Machines Market reflects the broader trends in the manufacturing industry, where automation and precision are becoming increasingly important. As industries continue to demand more sophisticated electronic devices, the role of press fit machines in the assembly process is expected to become even more critical, supporting the development of innovative products that meet the needs of consumers and businesses alike.

| Report Metric | Details |

| Report Name | Press Fit Machines Market |

| Accounted market size in year | US$ 101 million |

| Forecasted market size in 2031 | US$ 132 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TE Connectivity, Eberhard, Lazpiur, UMG Technologies, SYNEO, Harmontronics, Autosplice, Föhrenbach Application Tooling, Ept GmbH, Shenzhen Zhizhan Electronics, Nextronics Engineering, Kunming Connect Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |