What is Global 2-Methoxy-5-Methylbenzoic Acid Market?

The Global 2-Methoxy-5-Methylbenzoic Acid Market is a niche segment within the broader chemical industry, focusing on the production and distribution of a specific organic compound known as 2-Methoxy-5-Methylbenzoic Acid. This compound is a derivative of benzoic acid, characterized by the presence of methoxy and methyl groups, which contribute to its unique chemical properties. The market for this compound is driven by its applications in various industries, including pharmaceuticals, where it is used as an intermediate in the synthesis of active pharmaceutical ingredients (APIs). Additionally, it finds use in the production of dyes, fragrances, and other specialty chemicals. The demand for 2-Methoxy-5-Methylbenzoic Acid is influenced by factors such as advancements in chemical synthesis technologies, regulatory frameworks governing chemical production, and the overall growth of end-use industries. As a result, the market dynamics are shaped by both supply-side factors, such as production capacities and raw material availability, and demand-side factors, including the evolving needs of industries that utilize this compound. Overall, the Global 2-Methoxy-5-Methylbenzoic Acid Market represents a specialized area of the chemical industry with specific growth drivers and challenges.

Purity Above 99%, Purity Above 98% in the Global 2-Methoxy-5-Methylbenzoic Acid Market:

In the Global 2-Methoxy-5-Methylbenzoic Acid Market, the purity of the compound is a critical factor that influences its applications and market value. Purity levels are typically categorized as "Purity Above 99%" and "Purity Above 98%," each serving different industrial needs. Compounds with a purity above 99% are considered high-grade and are often used in applications where the highest quality is essential, such as in pharmaceuticals and high-end specialty chemicals. These applications demand stringent quality standards to ensure the efficacy and safety of the final products. The production of such high-purity compounds requires advanced purification techniques and rigorous quality control measures, which can increase production costs but also justify higher market prices. On the other hand, compounds with a purity above 98% are slightly less refined but still meet the quality requirements for many industrial applications. These are often used in sectors where ultra-high purity is not as critical, such as in the production of certain dyes, fragrances, and other industrial chemicals. The choice between these purity levels depends on the specific requirements of the end-use application, cost considerations, and regulatory standards. The market for 2-Methoxy-5-Methylbenzoic Acid with varying purity levels is influenced by factors such as technological advancements in purification processes, the availability of raw materials, and the competitive landscape of chemical manufacturers. Companies operating in this market must balance the cost of production with the demand for high-purity compounds, often investing in research and development to improve purification technologies and reduce costs. Additionally, regulatory compliance plays a significant role in determining the marketability of these compounds, as different regions may have varying standards for chemical purity and safety. As such, manufacturers must navigate a complex web of regulations to ensure their products meet the necessary criteria for global distribution. The demand for high-purity 2-Methoxy-5-Methylbenzoic Acid is also driven by the growing emphasis on quality and safety in end-use industries, particularly in pharmaceuticals, where the purity of chemical intermediates can directly impact the safety and efficacy of drugs. This has led to increased investments in quality assurance and control processes, as well as collaborations between chemical manufacturers and pharmaceutical companies to develop compounds that meet the highest standards. In summary, the Global 2-Methoxy-5-Methylbenzoic Acid Market is characterized by a focus on purity levels, with different applications and market dynamics associated with each category. The market is shaped by technological, regulatory, and economic factors, requiring manufacturers to continuously adapt to changing industry demands and standards.

Medicine, Other in the Global 2-Methoxy-5-Methylbenzoic Acid Market:

The usage of 2-Methoxy-5-Methylbenzoic Acid in the Global Market spans several areas, with medicine being one of the most significant. In the pharmaceutical industry, this compound serves as an important intermediate in the synthesis of various active pharmaceutical ingredients (APIs). Its unique chemical structure allows it to participate in reactions that form the backbone of many therapeutic agents. The demand for 2-Methoxy-5-Methylbenzoic Acid in medicine is driven by the continuous development of new drugs and the need for efficient and cost-effective synthesis routes. Pharmaceutical companies rely on high-purity compounds to ensure the safety and efficacy of their products, making the quality of 2-Methoxy-5-Methylbenzoic Acid a critical factor in its application. Beyond medicine, 2-Methoxy-5-Methylbenzoic Acid finds use in other industries, such as the production of dyes and fragrances. In the dye industry, it is used as a precursor for the synthesis of various colorants, contributing to the vibrant hues required in textiles, plastics, and other materials. The compound's chemical properties allow it to form stable bonds with other molecules, resulting in dyes that are both durable and vivid. Similarly, in the fragrance industry, 2-Methoxy-5-Methylbenzoic Acid is used to create aromatic compounds that are incorporated into perfumes, cosmetics, and personal care products. Its ability to impart a pleasant scent makes it a valuable ingredient in the formulation of fragrances that appeal to consumers. The versatility of 2-Methoxy-5-Methylbenzoic Acid extends to other applications as well, including its use as a building block in the synthesis of specialty chemicals. These chemicals are used in a wide range of industries, from agriculture to electronics, where they serve as intermediates in the production of more complex compounds. The demand for 2-Methoxy-5-Methylbenzoic Acid in these areas is influenced by factors such as technological advancements, consumer preferences, and regulatory requirements. As industries continue to evolve, the need for innovative and efficient chemical solutions drives the market for this versatile compound. In conclusion, the Global 2-Methoxy-5-Methylbenzoic Acid Market is characterized by its diverse applications across multiple industries. Its role as an intermediate in pharmaceutical synthesis, as well as its use in dyes, fragrances, and specialty chemicals, highlights its importance in the global chemical landscape. The market is driven by a combination of technological, economic, and regulatory factors, with manufacturers continuously seeking to improve production processes and meet the evolving needs of end-use industries.

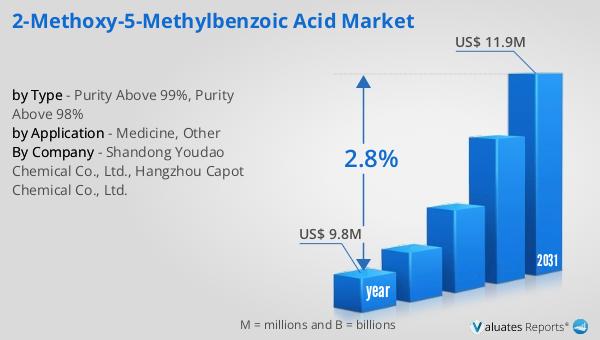

Global 2-Methoxy-5-Methylbenzoic Acid Market Outlook:

The global market for 2-Methoxy-5-Methylbenzoic Acid was valued at approximately $9.8 million in 2024, reflecting its niche yet significant role in the chemical industry. Over the years, this market is expected to experience steady growth, with projections indicating that it will reach an estimated size of $11.9 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 2.8% during the forecast period. The market's expansion can be attributed to several factors, including the increasing demand for high-purity chemical intermediates in the pharmaceutical industry, as well as the growing use of this compound in the production of dyes, fragrances, and specialty chemicals. The steady CAGR suggests a stable market environment, where demand is consistently met by supply, and manufacturers are able to adapt to changing industry needs. This growth is also indicative of the compound's versatility and the ongoing advancements in chemical synthesis technologies that enable more efficient production processes. As the market continues to evolve, stakeholders, including manufacturers, distributors, and end-users, will need to navigate the complexities of regulatory compliance, technological innovation, and competitive dynamics to capitalize on the opportunities presented by the Global 2-Methoxy-5-Methylbenzoic Acid Market.

| Report Metric | Details |

| Report Name | 2-Methoxy-5-Methylbenzoic Acid Market |

| Accounted market size in year | US$ 9.8 million |

| Forecasted market size in 2031 | US$ 11.9 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shandong Youdao Chemical Co., Ltd., Hangzhou Capot Chemical Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |