What is Global Automated Medication Dispensing and Storage Systems Market?

The Global Automated Medication Dispensing and Storage Systems Market is a rapidly evolving sector that focuses on the development and implementation of advanced technologies to streamline the process of medication management in healthcare settings. These systems are designed to enhance the accuracy, efficiency, and safety of medication dispensing and storage, thereby reducing the risk of human error and improving patient outcomes. Automated medication dispensing systems are utilized in various healthcare environments, including hospitals, clinics, and pharmacies, to ensure that patients receive the correct medications at the right time. These systems often incorporate features such as barcode scanning, electronic tracking, and secure storage to maintain the integrity of medications and prevent unauthorized access. By automating the dispensing process, healthcare providers can allocate more time to patient care and reduce the administrative burden associated with manual medication management. As the demand for efficient healthcare solutions continues to grow, the Global Automated Medication Dispensing and Storage Systems Market is expected to expand, driven by technological advancements and the increasing emphasis on patient safety and operational efficiency.

Robots/Robotic Automated Dispensing Systems, Carousels, Automated Dispensing Cabinets in the Global Automated Medication Dispensing and Storage Systems Market:

Robots and robotic automated dispensing systems are at the forefront of innovation in the Global Automated Medication Dispensing and Storage Systems Market. These systems utilize advanced robotics technology to automate the process of dispensing medications, significantly reducing the likelihood of human error. Robots in this context are designed to handle a wide range of tasks, from sorting and counting pills to packaging and labeling medications. They are equipped with sophisticated sensors and software that enable them to operate with high precision and speed, ensuring that each patient receives the correct dosage of medication. The use of robots in medication dispensing not only enhances accuracy but also improves efficiency by allowing healthcare providers to focus on more critical tasks. Carousels, another key component of automated dispensing systems, are designed to optimize the storage and retrieval of medications. These systems use rotating shelves to store medications in a compact and organized manner, making it easier for healthcare staff to access the required medications quickly. Carousels are often integrated with computerized systems that track inventory levels and expiration dates, ensuring that medications are dispensed in a timely and efficient manner. Automated dispensing cabinets (ADCs) are secure storage units that provide controlled access to medications. These cabinets are equipped with electronic locks and tracking systems that monitor the dispensing of medications, ensuring that only authorized personnel can access them. ADCs are commonly used in hospitals and clinics to store high-risk medications, such as narcotics, and are designed to prevent theft and misuse. By providing a secure and efficient means of storing and dispensing medications, ADCs play a crucial role in enhancing patient safety and reducing medication errors. The integration of these technologies into the Global Automated Medication Dispensing and Storage Systems Market is transforming the way medications are managed in healthcare settings, leading to improved patient outcomes and increased operational efficiency. As the healthcare industry continues to evolve, the adoption of robotic and automated dispensing systems is expected to grow, driven by the need for more efficient and accurate medication management solutions.

Inpatient Pharmacies, Outpatient Pharmacies, Retail Pharmacies, Pharmacy Benefit Management Organizations and Mail-Order Pharmacies in the Global Automated Medication Dispensing and Storage Systems Market:

The Global Automated Medication Dispensing and Storage Systems Market is making significant strides in various areas of healthcare, including inpatient pharmacies, outpatient pharmacies, retail pharmacies, pharmacy benefit management organizations, and mail-order pharmacies. In inpatient pharmacies, automated dispensing systems are used to streamline the process of medication management, ensuring that patients receive the correct medications in a timely manner. These systems help reduce the risk of medication errors and improve patient safety by automating the dispensing process and providing real-time tracking of medication usage. In outpatient pharmacies, automated systems are used to enhance the efficiency of medication dispensing and reduce wait times for patients. By automating the process of filling prescriptions, outpatient pharmacies can improve their workflow and provide better service to patients. Retail pharmacies also benefit from automated dispensing systems, which help manage inventory levels and ensure that medications are dispensed accurately and efficiently. These systems enable retail pharmacies to provide a higher level of service to their customers by reducing the likelihood of medication errors and improving the overall efficiency of the dispensing process. Pharmacy benefit management organizations use automated dispensing systems to manage the distribution of medications to patients, ensuring that they receive the correct medications at the right time. These systems help streamline the process of medication management and reduce the administrative burden associated with manual dispensing. Mail-order pharmacies also utilize automated dispensing systems to improve the efficiency of their operations and ensure that medications are delivered to patients in a timely manner. By automating the process of filling and shipping prescriptions, mail-order pharmacies can reduce the risk of errors and improve the overall quality of service they provide to their customers. The integration of automated dispensing systems into these areas of healthcare is transforming the way medications are managed, leading to improved patient outcomes and increased operational efficiency. As the demand for efficient healthcare solutions continues to grow, the adoption of automated dispensing systems is expected to increase, driven by the need for more accurate and efficient medication management solutions.

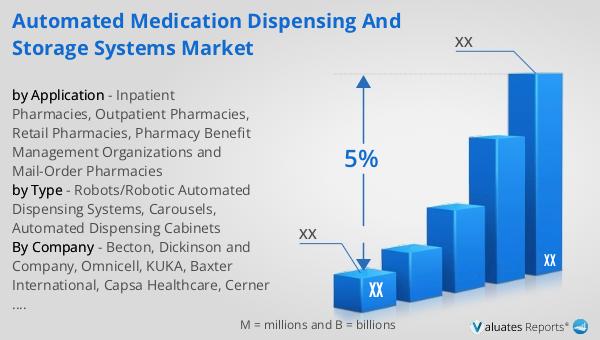

Global Automated Medication Dispensing and Storage Systems Market Outlook:

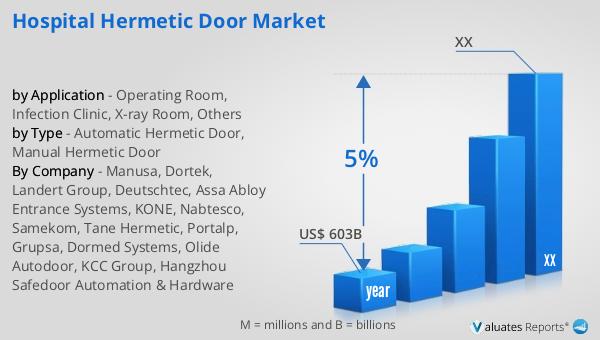

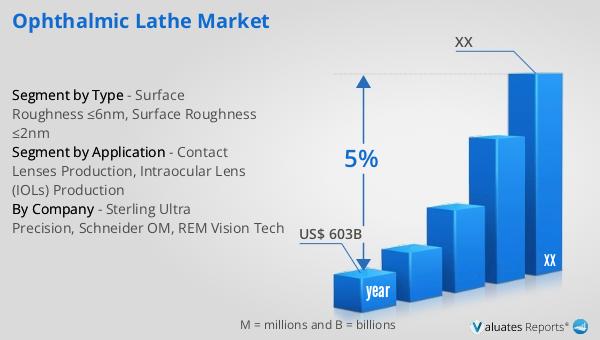

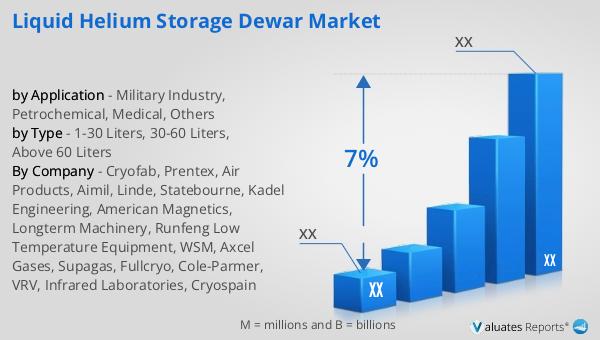

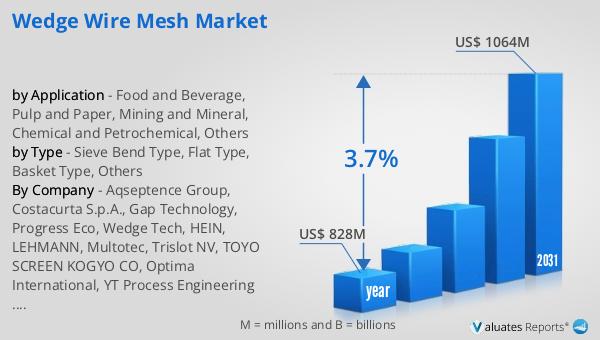

The outlook for the Global Automated Medication Dispensing and Storage Systems Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the need for efficient medication management solutions. In comparison, the chemical drug market experienced growth from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth highlights the expanding market for chemical drugs and the importance of automated dispensing systems in managing the distribution and storage of these medications. As the pharmaceutical industry continues to grow, the demand for automated medication dispensing and storage systems is expected to rise, driven by the need for more efficient and accurate medication management solutions. The integration of advanced technologies, such as robotics and computerized systems, into the Global Automated Medication Dispensing and Storage Systems Market is transforming the way medications are managed, leading to improved patient outcomes and increased operational efficiency. As healthcare providers continue to seek innovative solutions to enhance patient care and reduce costs, the adoption of automated dispensing systems is expected to increase, further driving the growth of this market.

| Report Metric | Details |

| Report Name | Automated Medication Dispensing and Storage Systems Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Becton, Dickinson and Company, Omnicell, KUKA, Baxter International, Capsa Healthcare, Cerner Corporation, Yuyama, ARxIUM, Parata Systems, RxSafe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |